Amino-functionalization magnetic silicon dioxide-ferroferric oxide composite nanomaterial and preparation method thereof

A technology of composite nanomaterials and ferric oxide, which is applied in the field of materials to achieve the effects of high extraction efficiency, large specific surface energy and enhanced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

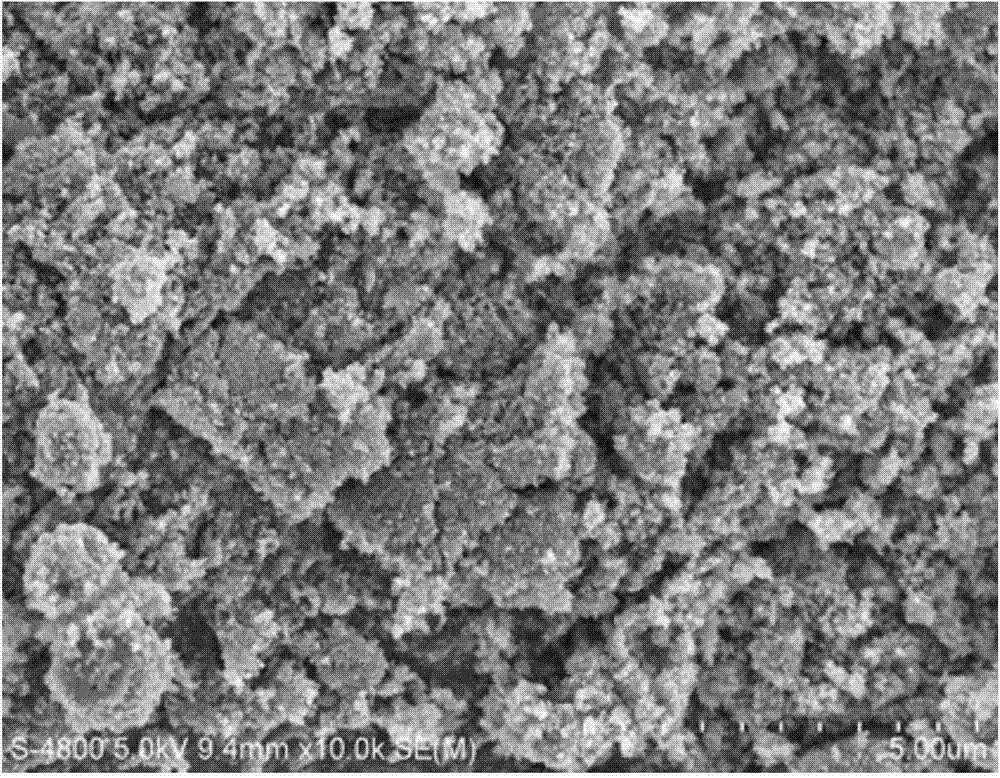

[0026] (1) Co-precipitation method to synthesize magnetic ferric oxide nanoparticles: According to the molar ratio of 1:1.2, FeSO 4 ·7H 2 O, FeCl 3 ·6H 2 O was made into an aqueous solution with deionized water aerated with nitrogen for 30 minutes, mixed in a three-necked flask, and under the protection of nitrogen, 5% ammonia water was added dropwise in the three-necked flask, while stirring at a speed of 240r / min until the pH of the solution 8; reacted at room temperature for 2 hours, the obtained product was separated by magnetic absorption and washed several times, and then dialyzed for 48 hours, then dried in vacuum at constant temperature to obtain black magnetic ferric oxide nanoparticles. The scanning electron microscope image of the prepared magnetic ferric oxide particles is shown in figure 1 .

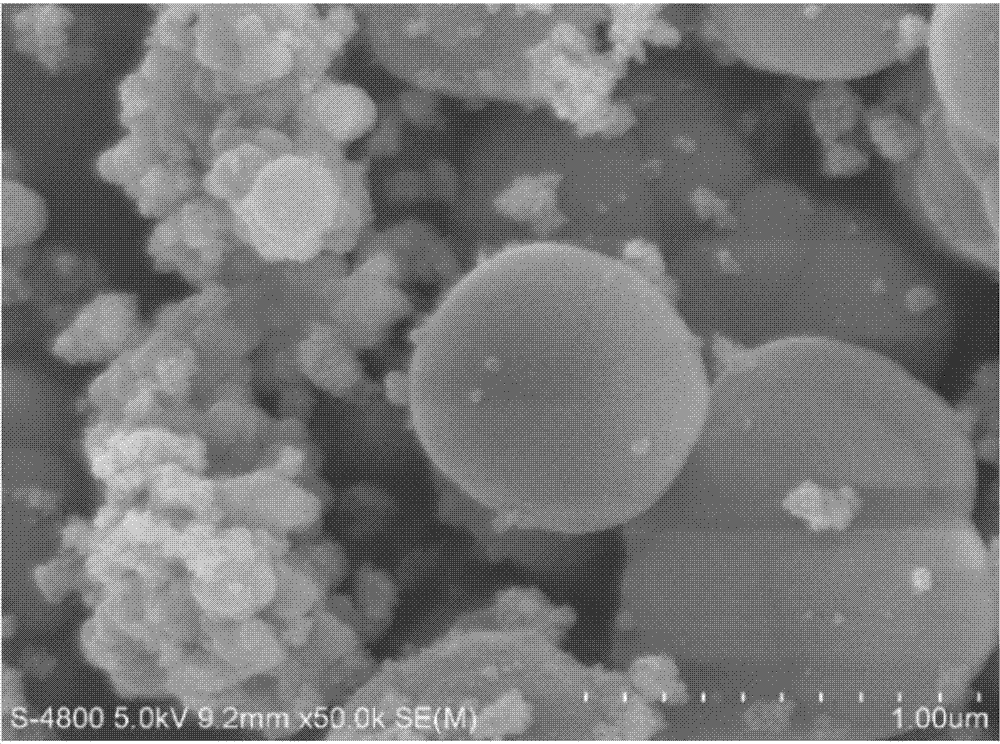

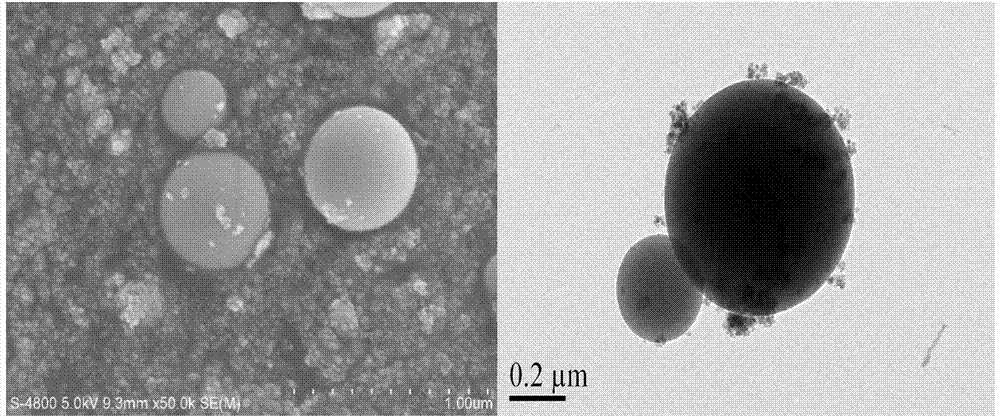

[0027] (2) Dissolve ferroferric oxide magnetic nanoparticles in ethanol, disperse them by ultrasonication for 1h, add 25% ammonia water, TEOS (tetraethyl orthosilicate),...

Embodiment 2

[0033] (1) Co-precipitation method to synthesize magnetic ferric oxide nanoparticles: According to the molar ratio of 1:1, FeSO4 ·7H 2 O, FeCl 3 ·6H 2 O was made into an aqueous solution with deionized water aerated with nitrogen for 30 minutes, mixed in a three-necked flask, and under the protection of nitrogen, 6% ammonia water was added dropwise in the three-necked flask, and stirred at a speed of 200 r / min at the same time until the pH of the solution was was 10; reacted at room temperature for 1 hour, and the obtained product was separated by magnetic suction and washed several times, and then dialyzed for 48 hours, then dried in constant temperature and vacuum to obtain black magnetic ferric oxide nanoparticles;

[0034] (2) Dissolve ferroferric oxide magnetic nanoparticles in ethanol, disperse them by ultrasonication for 1h, add 25% ammonia water, TEOS (tetraethyl orthosilicate), react for 1.5h, put the solution in an ultrasonic cleaning tank and ultrasonically for 6h,...

Embodiment 3

[0037] (1) According to the molar ratio of 1:2, FeSO 4 ·7H 2 O, FeCl 3 ·6H 2 O was made into an aqueous solution with deionized water aerated with nitrogen for 30 minutes, mixed in a three-necked flask, and under the protection of nitrogen, 4% ammonia water was added dropwise in the three-necked flask, and stirred at a speed of 300 r / min at the same time until the pH of the solution was for 9. After reacting at room temperature for 3 hours, the obtained product was separated by magnetic absorption and washed with water several times, and then dialyzed for 48 hours, then vacuum-dried at a constant temperature to obtain black magnetic ferric oxide nanoparticles.

[0038] (2) Dissolve ferroferric oxide magnetic particles in ethanol, disperse them by ultrasonication for 1h, add 25% ammonia water, TEOS (tetraethyl orthosilicate), react for 2h, put the solution in an ultrasonic cleaning tank and ultrasonically for 4h, then at 11000rpm Centrifuge at a rotating speed for 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com