combined filter

A filter and oil filtration technology, applied in filtration circuits, filtration separation, chemical instruments and methods, etc., can solve the problems of poor filter holding capacity, short maintenance cycle, increased flow resistance, etc., to reduce pollutant deposition, The effect of prolonging the maintenance period and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

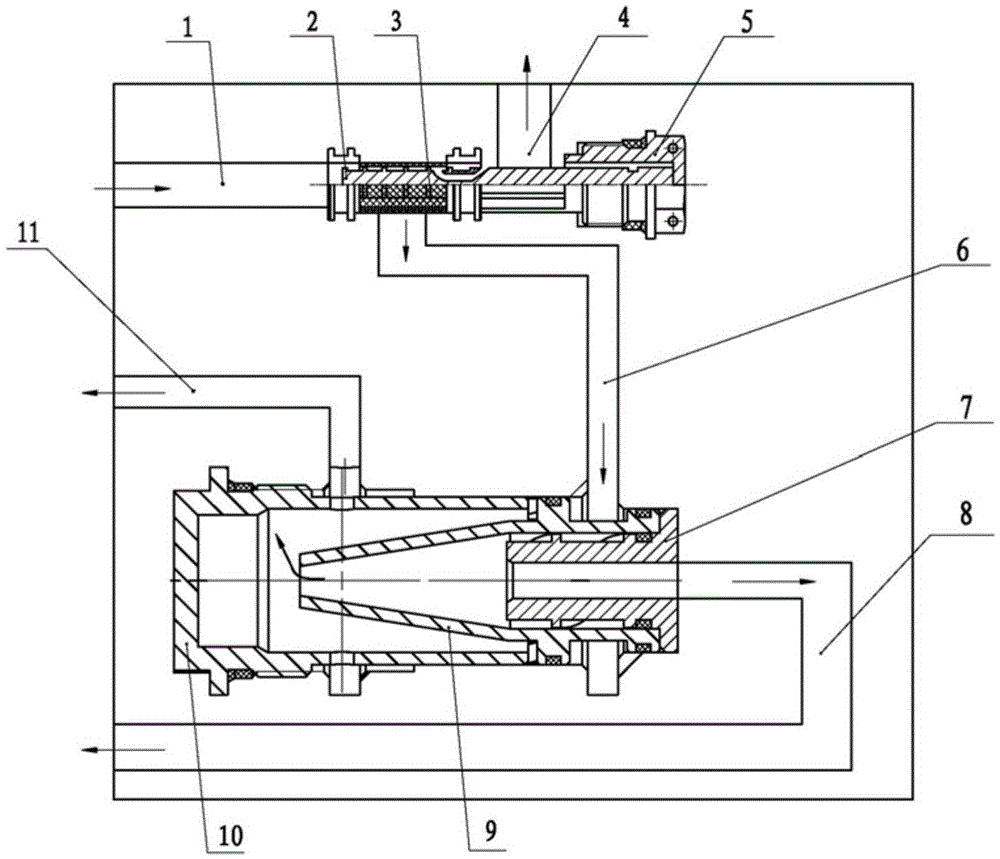

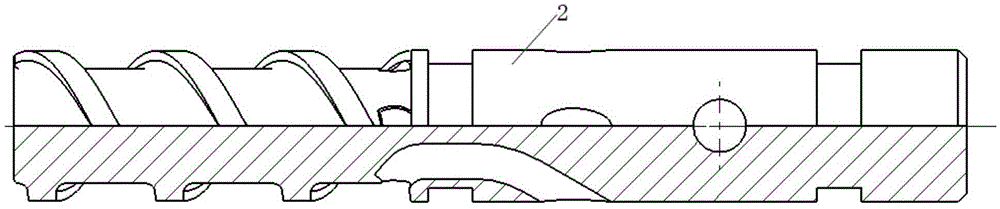

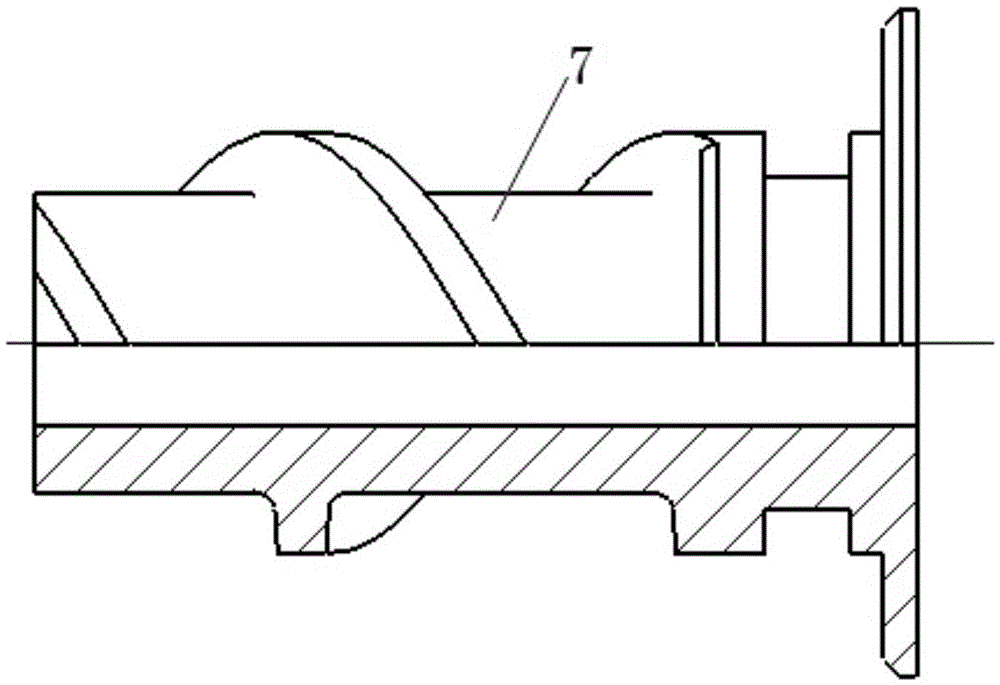

[0014] Figure 1~3 Including self-flushing oil filter inlet pipe 1, turbulence promoter 2, self-flushing oil filter screen 3, self-flushing oil filter return pipe 4, self-flushing oil filter skeleton 5, vortex oil filter inlet pipe 6, guide vane 7 , Vortex oil filter outlet pipe 8, tapered cavity 9, dirt collection tank 10, vortex oil filter return oil port pipe 11, etc.

[0015] Such as figure 1 As shown, the present invention is a combined filter, comprising a self-flushing oil filter framework 5, the oil return port of the self-flushing oil filter framework 5 is connected with a self-flushing oil filter return pipe 4, and the self-flushing oil filter framework 5 inlet The end is fixedly connected to the turbulence promoter 2, and the inlet end of the turbulence promoter 2 is connected with the self-flushing oil filter inlet pipe 1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com