Medicine dispensing needle

A needle and needle bar technology, applied in the field of medical supplies, can solve the problems of safety of blocked needles, inability to clean the needle tip, hidden dangers, etc., and achieve the effects of increasing the suction volume, reducing the contact area, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

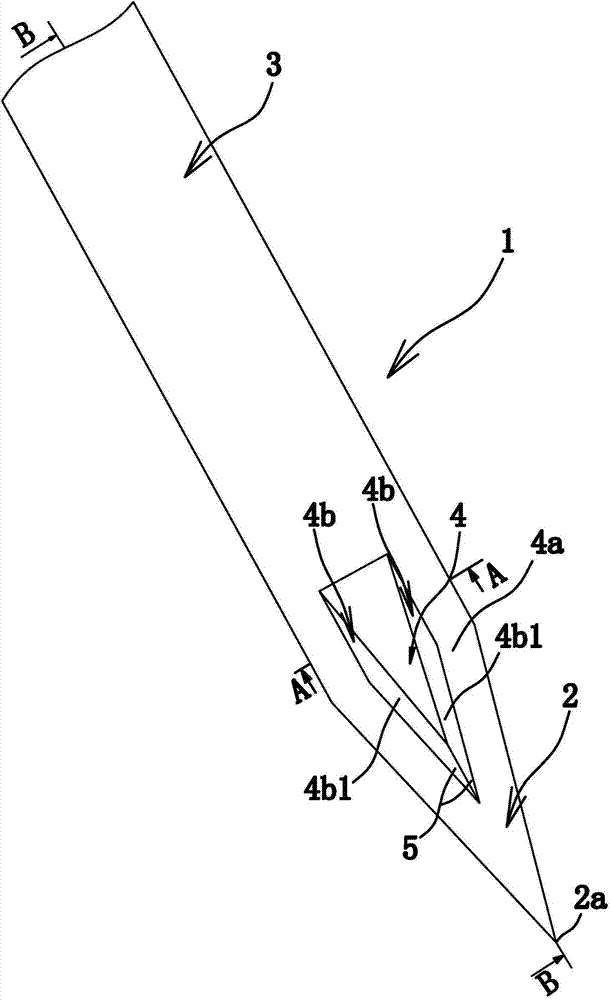

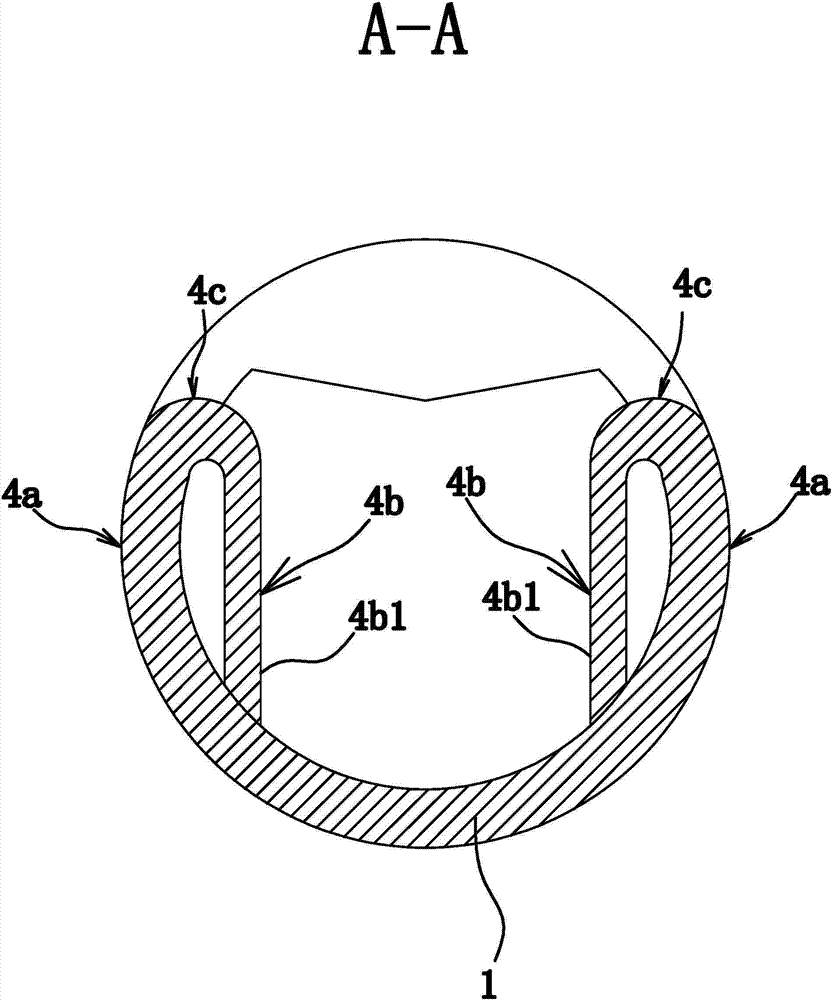

[0032] Such as figure 1 and Figure 4 As shown, the dispensing needle includes a hollow and rod-shaped body 1, the outer surface of the body 1 has a conical needle point 2 and a cylindrical needle shaft 3, and the front end of the needle point 2 is a needle point 2a .

[0033] Such as figure 1 As shown, the junction of the needle shaft part 3 and the needle tip part 2 is provided with a strip-shaped drug inlet hole 4, the drug inlet hole 4 communicates with the inner cavity of the body 1, and the drug inlet hole 4 has a strip-shaped opening. The direction of the shape is consistent with the axial direction of the main body 1. Such as figure 2 As shown, the opening of the medicine inlet hole 4 is the nearest point from the needle tip 2a to the needle tip 2 of the section of the needle tip 2a is a solid cone 2b, that is, the medicine inlet 4 is opened on the solid section of the needle tip 2, so that the needle tip The hollow section on the part 2 is completely exposed to ...

Embodiment 2

[0039] The structure and principle of the second embodiment are basically the same as the first embodiment, the difference is that: Figure 6 As shown, one end of the drug inlet hole 4 located on the needle tip 2 is roughly trapezoidal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com