Steam cooling machine capable of increasing steam utilization rate

A technology of cooking machine and utilization rate, applied in the field of kitchen utensils, can solve the problems of low utilization rate of steam, potential safety hazards, large heat dissipation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

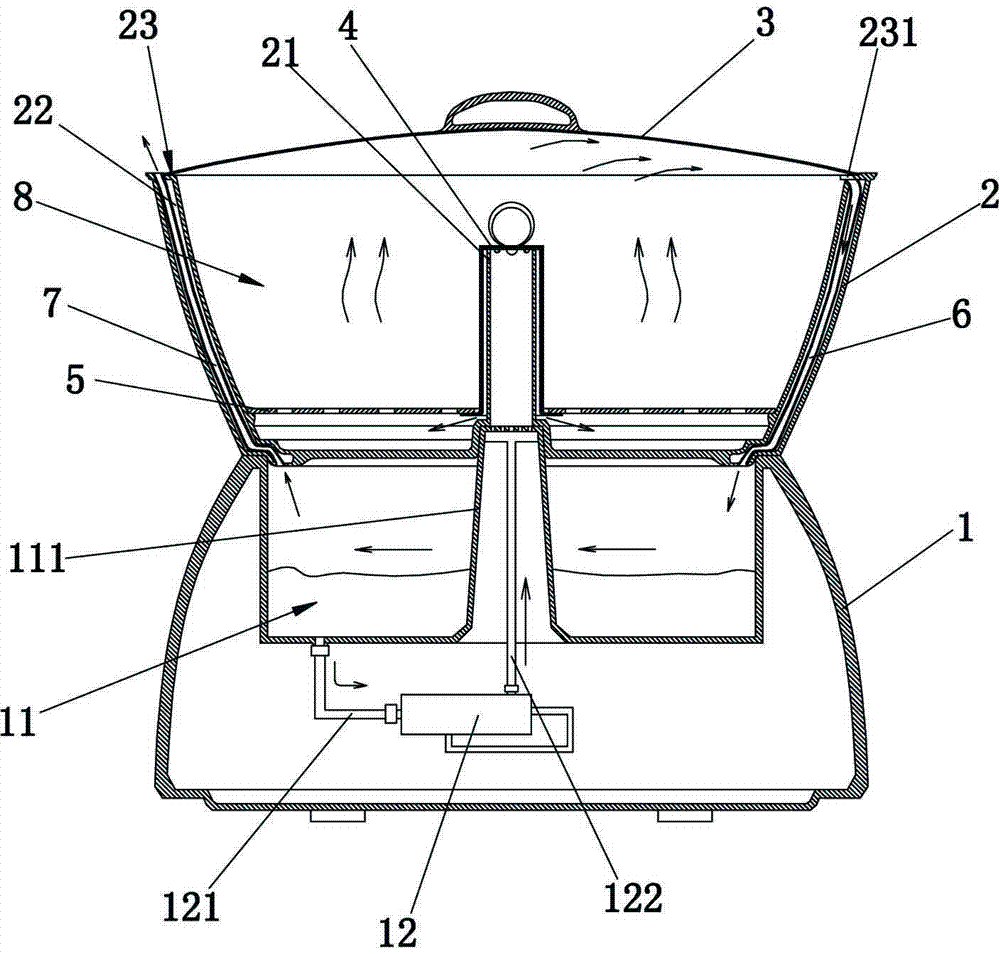

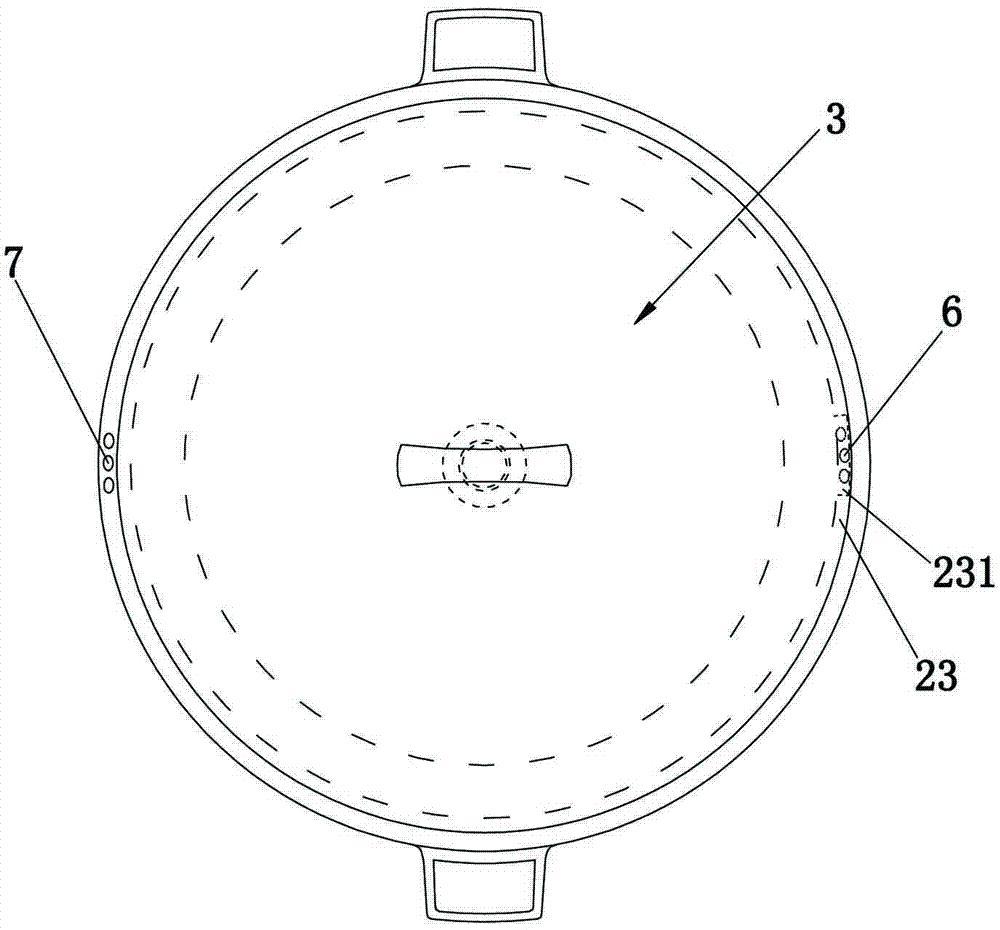

[0024] Such as figure 1 and figure 2 As shown, a steam cooking machine that can improve the utilization rate of steam includes a heating base 1 , a pot body 2 and a pot cover 3 . The heating seat 1 is provided with a steam generating device 12 and its control circuit (not shown in the figure). A water tank 11 is provided at the middle and upper part of the heating seat 1 , and the middle position of the bottom of the water tank 11 rises upwards to form a sleeve 111 . A plurality of steam holes are provided on the upper surface of the sleeve 111 ; When in use, the pot body 2 is placed on the upper end surface of the heating seat 1 , and the steam conduit 21 is docked with the casing 111 . The water in the water tank 11 flows into the steam generating device 12 through the pipe body 121 and is heated into steam, and the steam is transported to the steam conduit 21 by the steam nozzle 122 socketed with the sleeve 111, and then diffused into the whole pot. The upper end of th...

Embodiment 2

[0030] Such as Figure 4 As shown, the main difference between Embodiment 2 and Embodiment 1 lies in the arrangement of the exhaust pipe 7: the bottom edge of the pot body 2 is provided with a recess 24 leading from the water tank 11 to the outside of the steam cooking machine. As a preferred solution, The exhaust pipe 7 is arranged in the recess 24 in a manner of filling the recess 24, so as to ensure the simplicity and beauty of the shape of the pot body 2 . As another embodiment, the recess 24 can also be directly used as the exhaust pipe 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com