Processing method and processing device of dried dragon fruit slices

A processing method and technology of dragon fruit, applied in the field of processing dried dragon fruit slices, can solve the problems of complex process, high energy consumption, inability to emit sesame aroma and taste, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

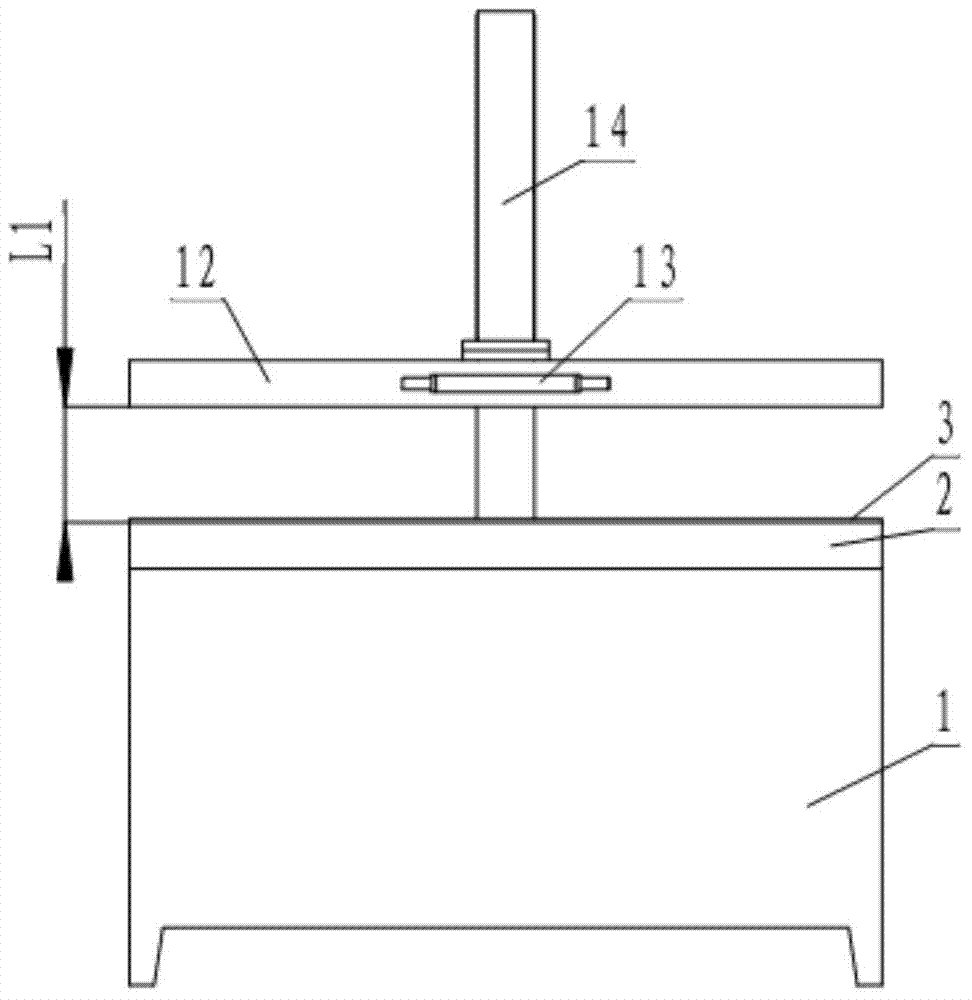

[0026] Example 1 (double-sided heating equipment for making dried dragon fruit slices)

[0027] see Figure 1~3 , the front side of the upper surface of the chassis 1 is provided with a lower ceramic heating plate 2 and a dry dragon fruit mold 3 in sequence from bottom to top, and a vertical column 4 is provided on the rear side, and the upper end of the column 4 is bent and extends to the front side with a cross arm 5. The end of the cross arm 5 is located directly above the lower ceramic heating plate 2, and is provided with a vertically downward telescopic telescopic mechanism 14. The lower end of the telescopic telescopic mechanism 14 is provided with an upper ceramic heating plate 12 for heating the ceramics. The front side of the plate 12 is provided with a handle 13 .

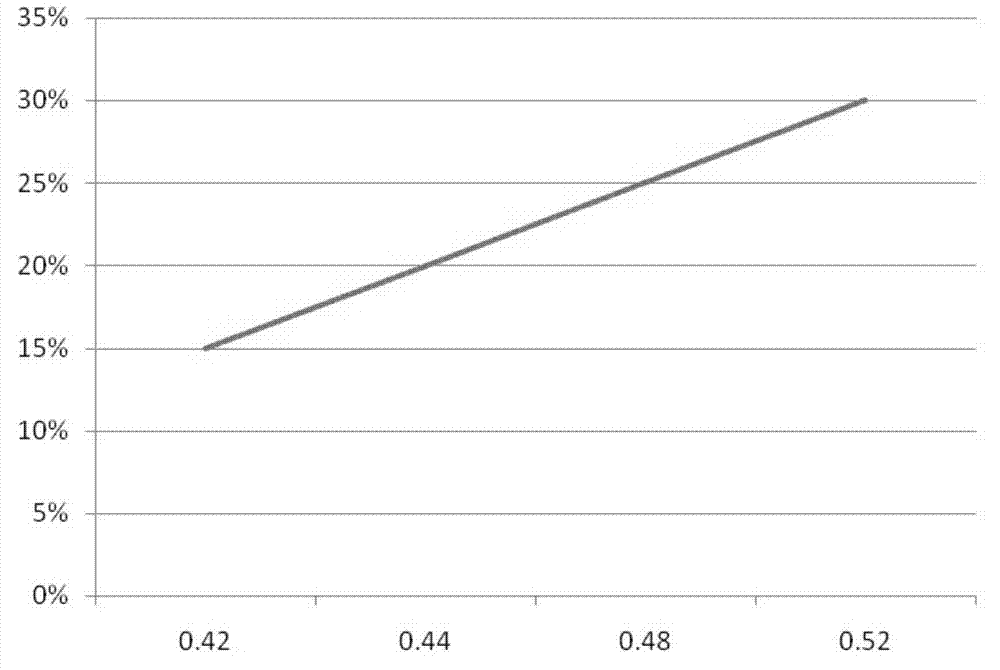

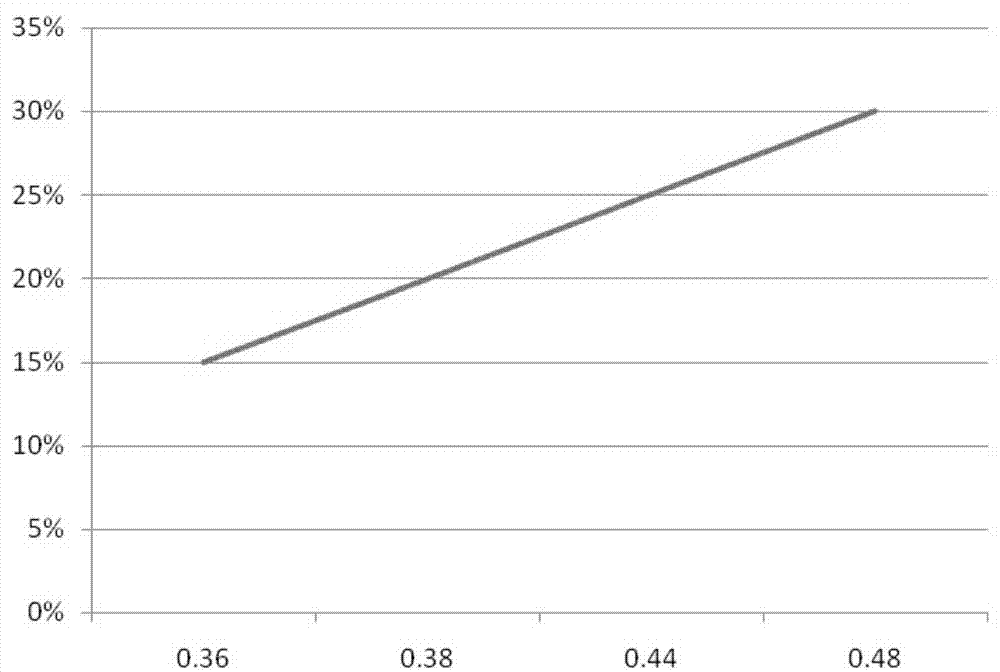

[0028] see Figure 4 and Figure 5 , the dried dragon fruit sheet mold 3 is a rectangular frame, and its thickness H depends on the thickness of the dried dragon fruit sheet, and the concrete calculat...

example 2

[0032] Example 2 (processing dried dragon fruit slices with skin)

[0033] The preparation method of the dried dragon fruit slice of this example is made up of the following steps:

[0034] (1) raw material sorting, select for use fresh, no damage by diseases and insect pests, eight to nine ripe, medium-sized fleshy red pitaya fruits without mildew and deterioration;

[0035] (2) wash the dragon fruit surface with flowing tap water;

[0036] (3) The two ends of the fruit are cut off;

[0037] (4) The fruit cut off at both ends is horizontally sliced into thin slices with a thickness of 4 mm to obtain fruit slices;

[0038] (5) Quickly immerse the fruit slices in the color-protecting agent and soak for 40 minutes, then wash with clear water to remove the color-protecting agent on the surface of the fruit slices; wherein, the color-protecting agent consists of the following components by weight percentage: ascorbic acid 0.60% , citric acid 0.80%, salt 0.70%, and the rest is...

example 3

[0042] Example 3 (processing of dried dragon fruit slices without skin)

[0043] (1) raw material sorting, select for use fresh, no damage by diseases and insect pests, eight to nine ripe, medium-sized fleshy red pitaya fruits without mildew and deterioration;

[0044] (2) wash the dragon fruit surface with flowing tap water;

[0045] (3) Cut off the two ends of the washed fruit;

[0046] (4) the fruit with two ends cut off is manually peeled;

[0047] (5) slice the peeled fruit horizontally into thin slices with a thickness of 5 mm to obtain fruit slices;

[0048] (6) Quickly immerse the fruit slices in the color-protecting agent and soak for 60 minutes, then wash with clear water to remove the color-protecting agent on the surface of the fruit slices; wherein, the color-protecting agent is composed of the following components by weight percentage: ascorbic acid 1.00% , citric acid 0.60%, salt 0.50%, and the rest is water;

[0049] (7) Put the dragon fruit slices processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com