Method for preparing physically reproducible protein chip

A technology for regenerating proteins and protein solutions, applied in biological testing, material inspection products, measuring devices, etc., can solve problems such as reduced concentration, opaque chips, and difficult quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

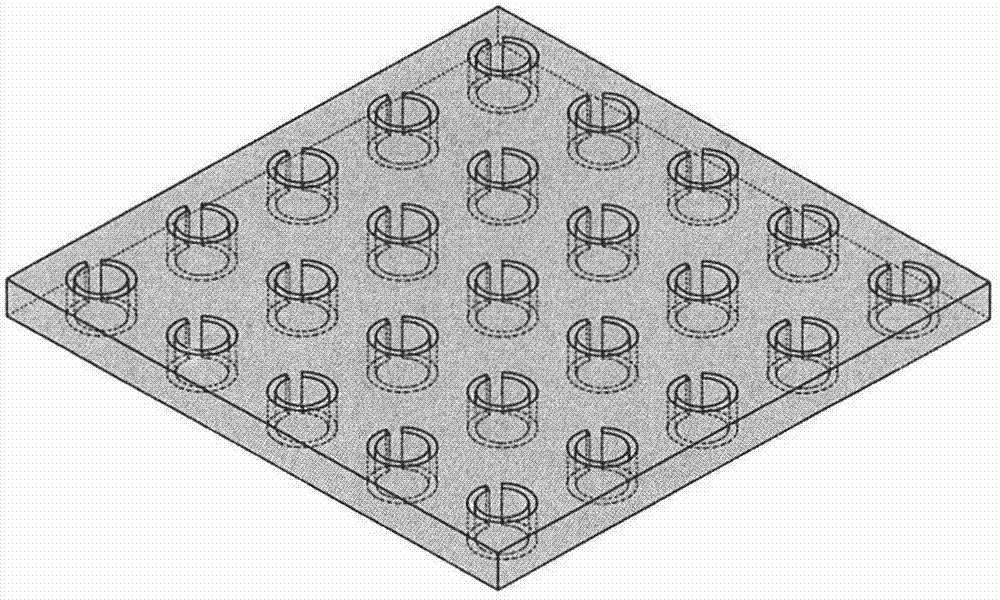

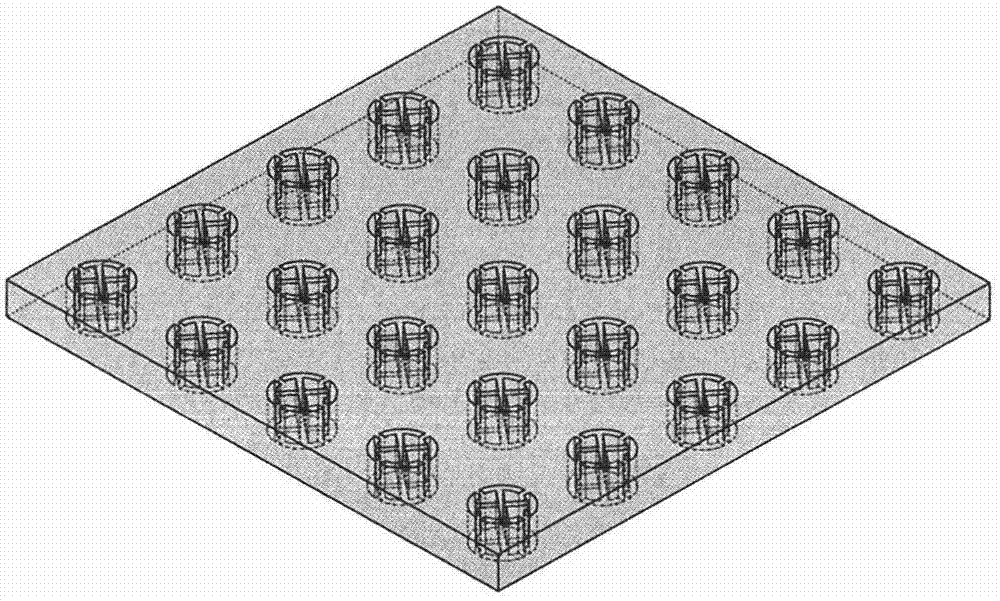

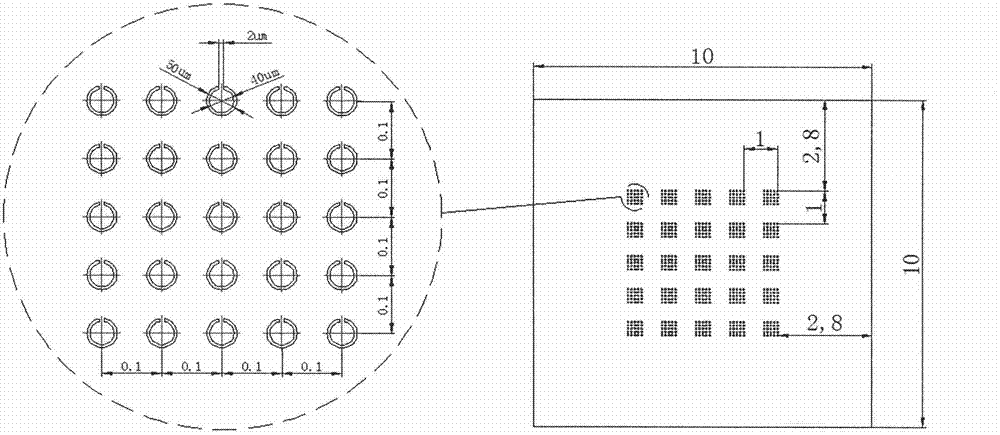

[0012] The first step is to design array and pattern design.

[0013] The first is to design the structure of a single lattice corresponding to the cylinder according to the use requirements and manufacturing process. The structural design of the barrel is cylindrical, preferably cylindrical to avoid stress concentration at the corners. The outer diameter of the tube is 10-100 microns, the height is 10-100 microns, and the wall thickness of the tube is 3-10 microns; each tube has 1-4 slits on the side, and the width of the slits is 1-5 microns. The barrel can be a single barrel, or a composite barrel divided by ribs with a thickness of 3-10 microns.

[0014] figure 1 and figure 2 Corresponding to two optimal design examples of single cylinder and multiple cylinders respectively. for figure 1 The single cylinder structure shown has an outer diameter of 50 microns, a wall thickness of 5 microns, and a depth of 30 microns. There is a slit in the wall of the cylinder, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com