Material flameless pyrolysis and flame combustion experiment box capable of changing environment stress and atmosphere conditions

An environmental pressure and experimental box technology, applied in the direction of chemical analysis using combustion, can solve the problems of lowering the pressure and changing the oxygen concentration, changing the atmospheric conditions, narrowing the pressure range, etc., to achieve stable working capacity, stable radiant heat flow, and improved visibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

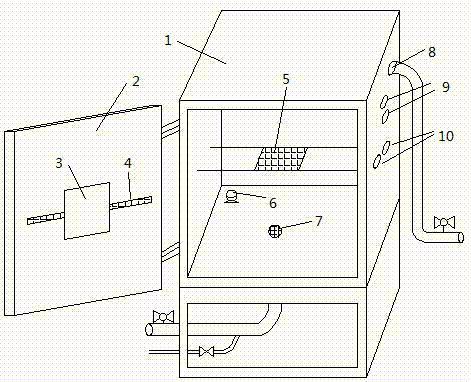

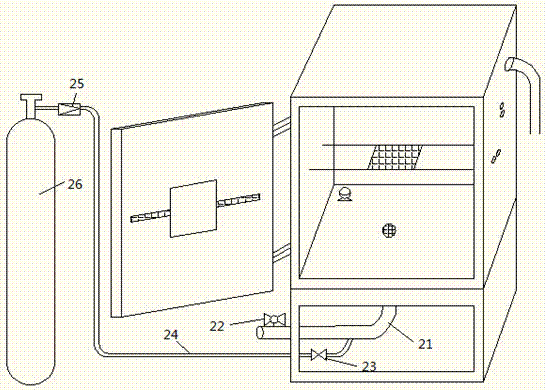

[0040] like figure 1 and figure 2 As shown, a material flameless pyrolysis and flame combustion test box capable of changing environmental pressure and atmospheric conditions according to the present invention includes a reaction box 1, and a test box door 2 is installed on the side of the reaction box 1. The test box door 2 is installed on the reaction box body 1 through a hinge, and a sealed environment is realized when the test box door 2 is closed. The door 2 of the experiment box is provided with an observation window 3. The length of the observation window 3 is 30 cm and the width is 30 cm, which can realize real-time observation of the experimental samples during the experiment. The bottom of the reaction box 1 has an air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com