A garbage incinerator with a separation device

A technology of waste incinerator and separation device, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of low waste treatment efficiency, incomplete smoke elimination, and inexhaustible ash powder combustion, and achieve a scientific method of waste treatment. , avoid environmental pollution or energy waste, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

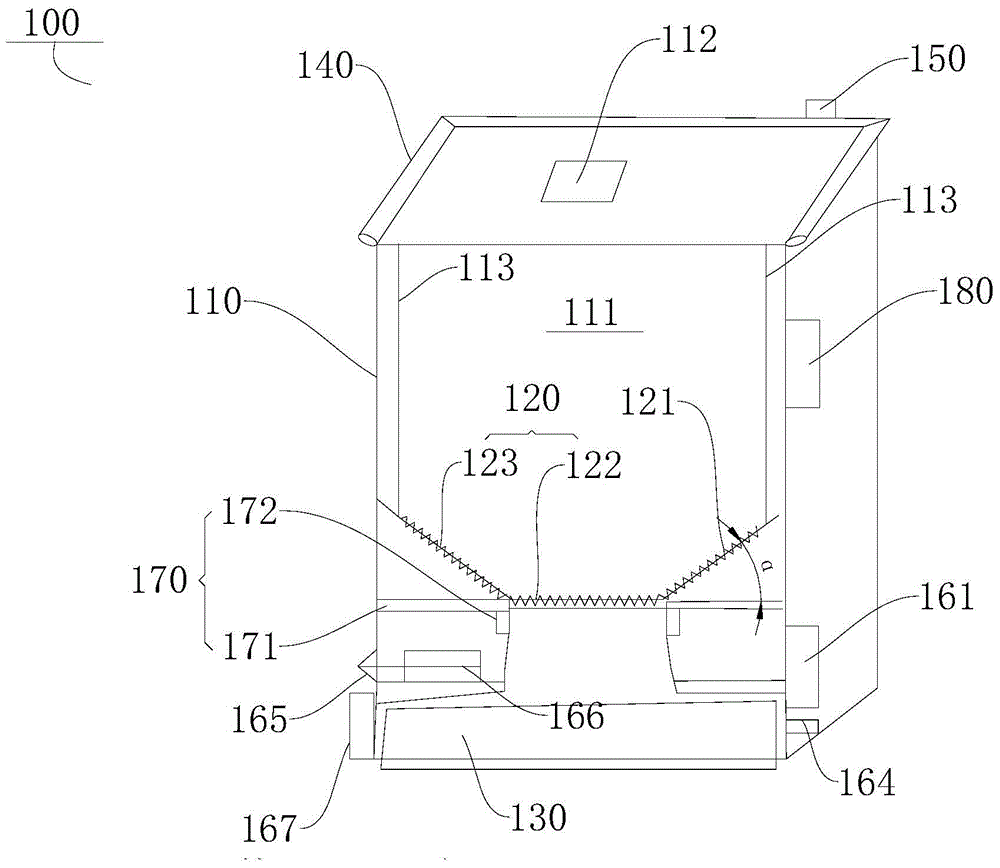

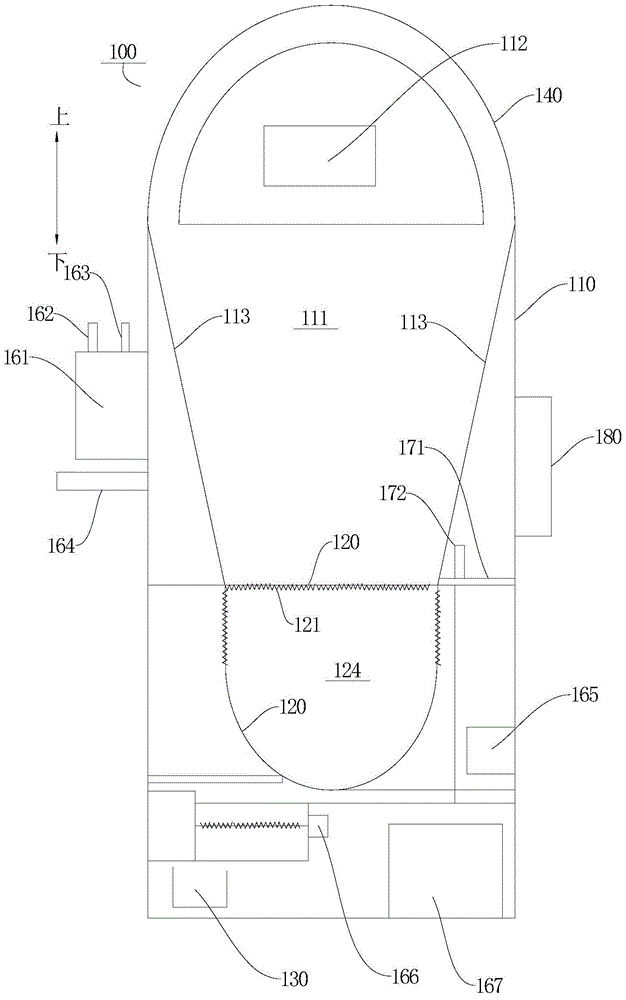

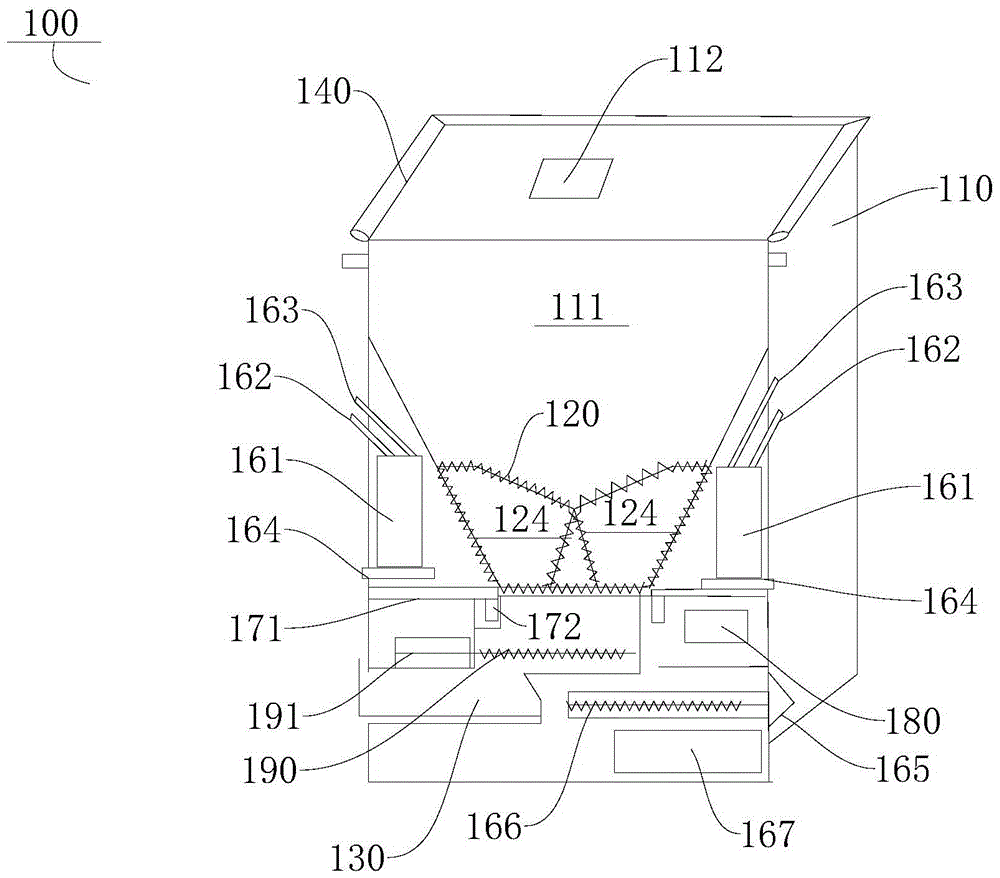

[0033] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0034] Such as Figure 1-Figure 3 As shown, a waste incinerator 100 with a separation device according to an embodiment of the present invention includes: a housing 110, a catalytic split plate 120, a gas furnace 164, and an energy conversion device.

[0035] Specifically, the casing 110 has a chamber 111 inside, and a garbage throwing door 112 is provided on the top of the chamber 111 . The top of the casing 110 is provided with a smoke discharge port (not shown in the figure), and the gas generated when the garbage is burned in the chamber 111 can be discharged through the smoke discharge port. Garbage can be thrown into the chamber 111 from the garbage throw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com