Non-aqueous solvent dyeing method of washing-free reactive dye

A reactive dye and non-aqueous solvent technology, applied in the dyeing of reactive dyes and non-aqueous solvent dyeing of reactive dyes with no water, can solve the problems of low fixation rate of reactive dyes, easy dyeing, and fast dyeing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of method for non-aqueous solvent dyeing of non-water-washing reactive dyes, and it comprises the following steps:

[0032] Soak 10g of pure cotton knitted fabric in an aqueous sodium carbonate solution with a concentration of 10g / L to swell, then soak twice and roll twice to control the liquid retention rate to 100%, and bake at 60°C for 10min;

[0033] Put the knitted fabric pretreated with sodium carbonate aqueous solution in the dyeing cup, add 0.3g (3% o.m.f) Avitera Red SE dye, 50mL dimethyl sulfoxide, dye at 50°C, and heat up at 1°C / min Slowly raise the temperature, slowly add 300mL of tetrachlorethylene during the heating process, raise the temperature to 130°C and keep it for 2h;

[0034] Take out the dyed cloth sample, place it in 50mL tetrachlorethylene solution of octadecyltrimethylammonium bromide with a concentration of 1g / L, keep it warm at 40°C for 30min, take it out, dry it, and complete the dyeing.

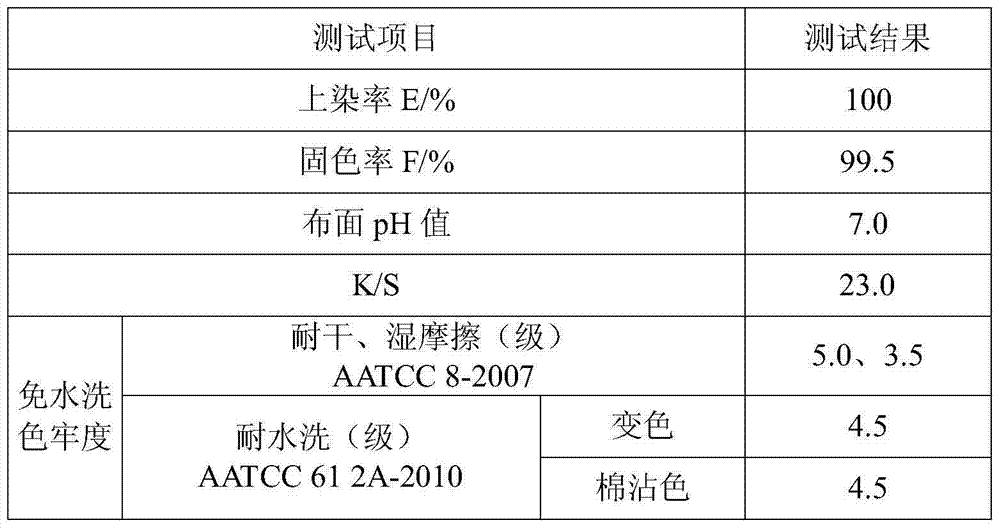

[0035] Two g...

Embodiment 2

[0039] The present embodiment provides a kind of method for non-aqueous solvent dyeing of non-water-washing reactive dyes, and it comprises the following steps:

[0040] Soak 10g of cotton / linen (60% cotton + 40% linen) blended knitting fabrics in a sodium carbonate solution with a concentration of 15g / L for 10 minutes at room temperature, dipping and rolling, control the liquid retention rate to 100%, and then dry , the drying temperature is 60°C, and the drying time is 10 minutes;

[0041] Put the knitted fabric pretreated by sodium carbonate solution in the dyeing cup, add 0.3g (3% o.m.f) Avitera Orange SE dye, 50mL of N,N-dimethylacetamide, dye at 50°C, and dye at 1°C Slowly raise the temperature at a heating rate of / min, slowly add 300mL of n-heptane during the heating process, and raise the temperature to 130°C for 2 hours;

[0042] Take out the dyed cloth sample, place it in 50 mL of 1 g / L dimethyl dioctadecyl ammonium chloride solution in tetrahydrofuran, keep it war...

Embodiment 3

[0047] The present embodiment provides a kind of method for non-aqueous solvent dyeing of non-water-washing reactive dyes, and it comprises the following steps:

[0048] Soak 10g of cotton / nylon (70% cotton + 30% nylon) blended knitting arrangement in a sodium bicarbonate solution with a concentration of 20g / L for 10 minutes at room temperature, dipping and rolling, control the liquid retention rate to 100%, and then dry Drying, the drying temperature is 60°C, and the drying time is 10 minutes.

[0049] Put the knitted fabric pretreated by sodium bicarbonate solution in the dyeing cup, add 0.3g (3% o.m.f) Avitera Blue SE dye, 50mL of N,N-dimethylformamide, dye at 50°C, and dye at 1 The heating rate of ℃ / min was raised slowly, and 300mL of n-hexane was slowly added during the heating process, and the temperature was raised to 130°C for 2 hours;

[0050] Take out the dyed cloth sample, place it in 40mL of acetone solution of 1g / L didodecyldimethylammonium bromide, keep it warm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com