Folding mechanism and its folding process

A technology of a process and a driving mechanism, applied in the field of folding technology, can solve the problems of reducing product quality, unsightly products, low work efficiency, etc., and achieve the effects of high processing efficiency, beautiful clothing, and simple folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

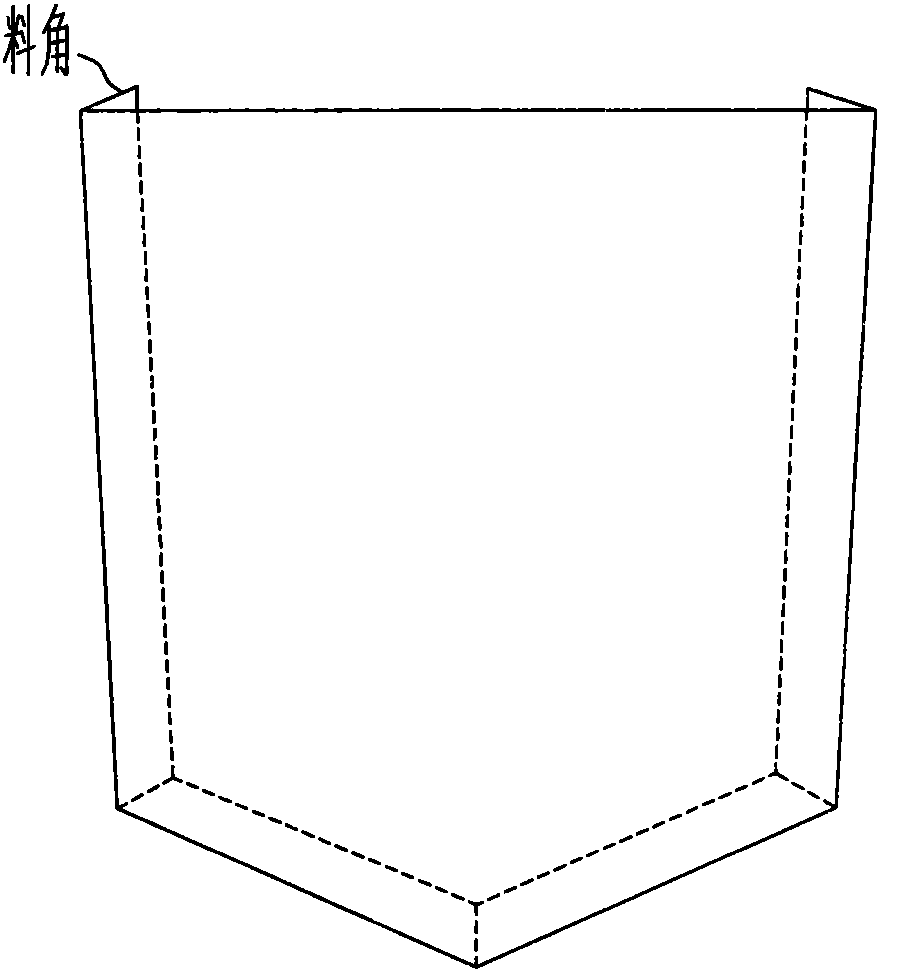

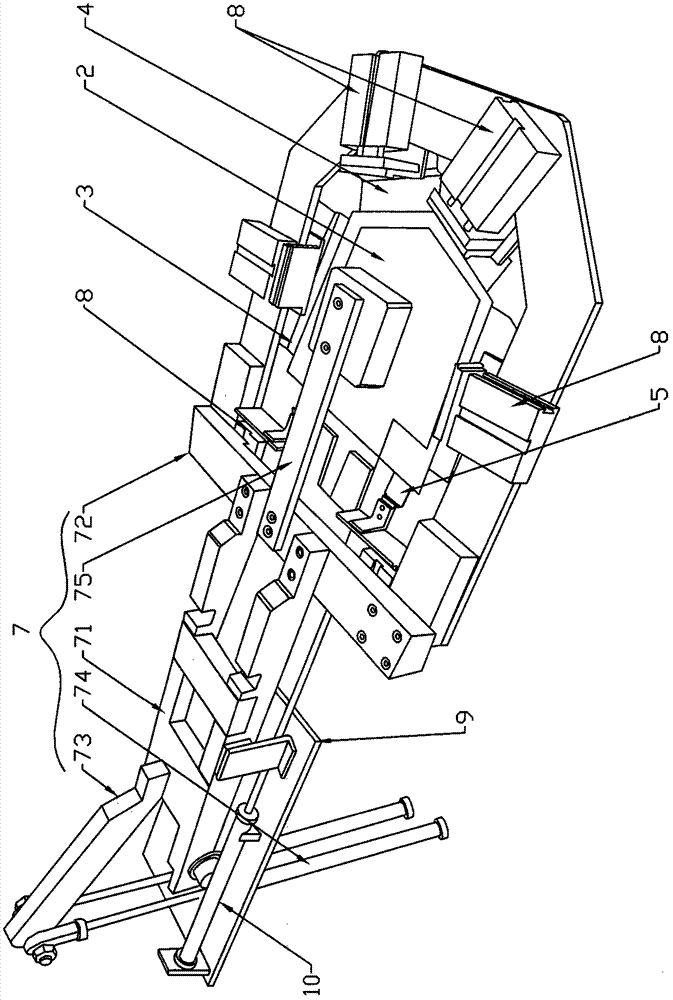

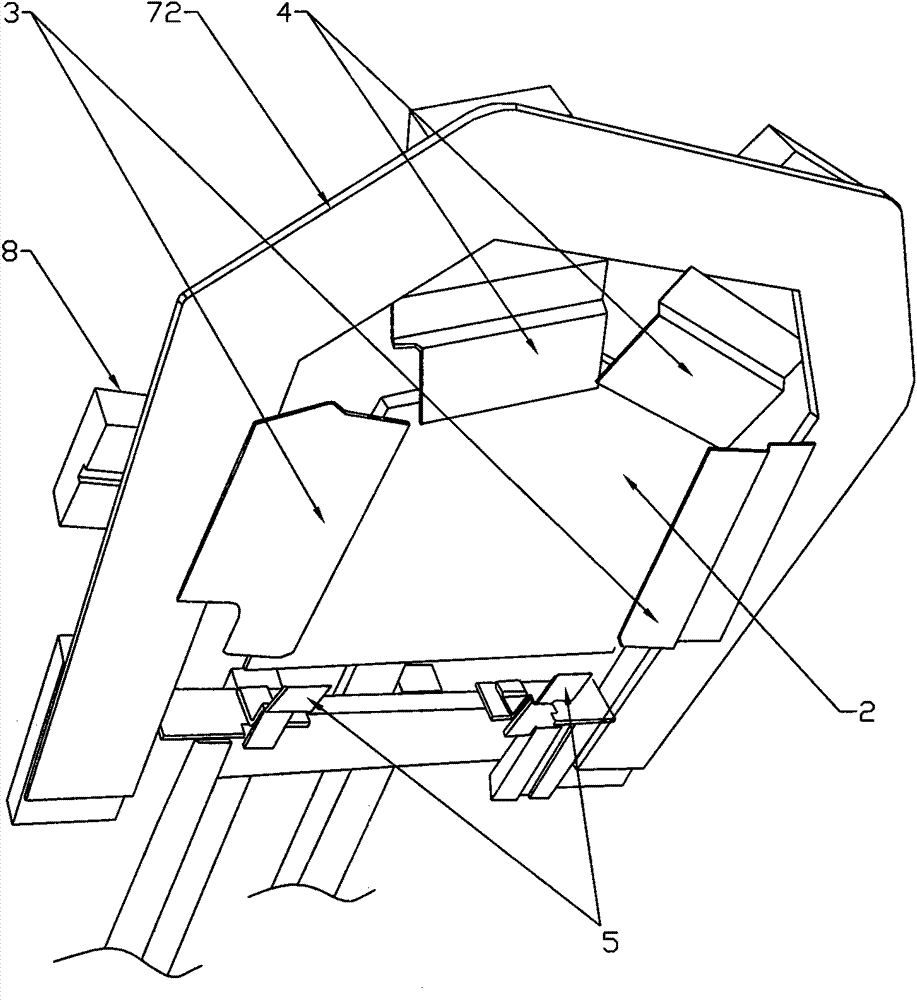

[0027] Such as Figure 1 to Figure 4 As shown, in this embodiment, the folding mechanism includes a discharge plate 1, a pressing plate 2 adapted to the discharge plate 1, a side folding sheet 3 and a bottom folding sheet 4, the folding The material mechanism also includes angled pieces 5 arranged on both sides of the front portion of the discharge plate 1, the front end of the side folded material 3 is provided with a bevel 6, when folding, the angled piece 5 is located Below the material plate 1 , the front end of the side flap 3 is located between the discharge plate 1 and the corner flap 5 .

[0028] In this embodiment, the folding mechanism further includes a lifting mechanism 7, and the lifting mechanism 7 is provided with Matched driving mechanism 8.

[0029] In this embodiment, the lifting mechanism 7 includes a swing rod 71 hinged to the base 9, a support frame 72 arranged at the front end of the swing rod 71, a pull rod 73 connected to the swing rod 71, and a pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com