Process for electrostatic powder spraying of melted powder on steel door surface

An electrostatic powder and electrostatic spraying technology, which is applied in the coating process and coating of metal materials, can solve the problems of uneven adhesion, instability, and peeling of the decorative surface, and achieve saving of baking equipment, strong uniformity, The effect of fast induction heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

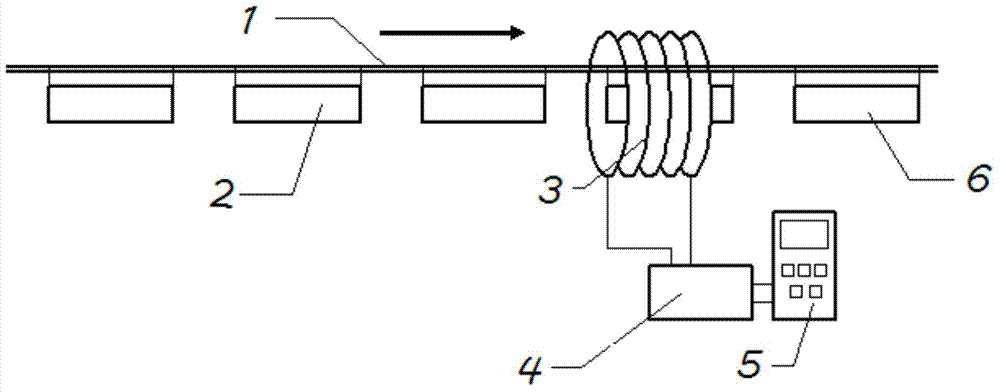

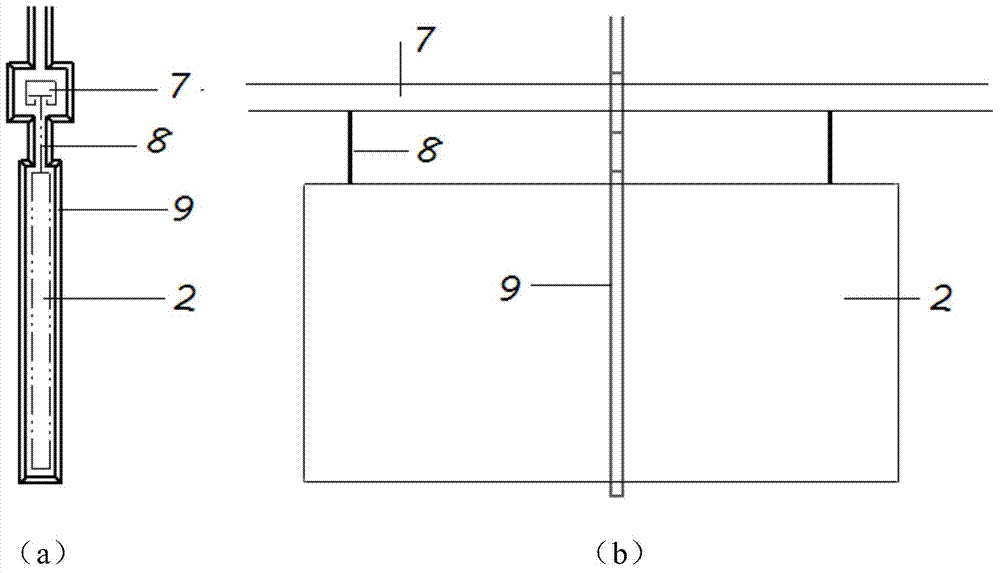

[0024] Such as figure 1 As shown, a melting powder process for electrostatic powder spraying on the surface of steel doors, a horizontal suspension transmission chain 1 is set, its rear end (left side in the figure) is connected to the electrostatic spraying equipment on the production line, and its front end (figure Middle right side) runs through an induction coil 3; the induction coil is connected with an intermediate frequency induction generator 4, and the intermediate frequency induction generator applies a specific intermediate frequency electromagnetic field to the induction coil 3 through a control box 5. The steel doors 2 to be melted powder that have been sprayed with electrostatic powder are suspended at equal intervals on the transmission chain. The steel doors 2 to be melted powder are suspended on the transmission chain in a horizontal manner, and follow the transmission chain to move from the rear end to the front end at a uniform speed, and enter one by one. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com