Wind shielding quilt with carbon nanofiber electric heating fabric

A technology of carbon nanofibers and nanofibers, which is applied in the field of smart wearable electric heating textile materials, can solve the problems of displacement between fabric lines and carbon fiber lines, uneven heat conduction of heating fabrics, poor toughness of carbon fibers, etc., and achieve uniform heating and stable heating temperature control, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

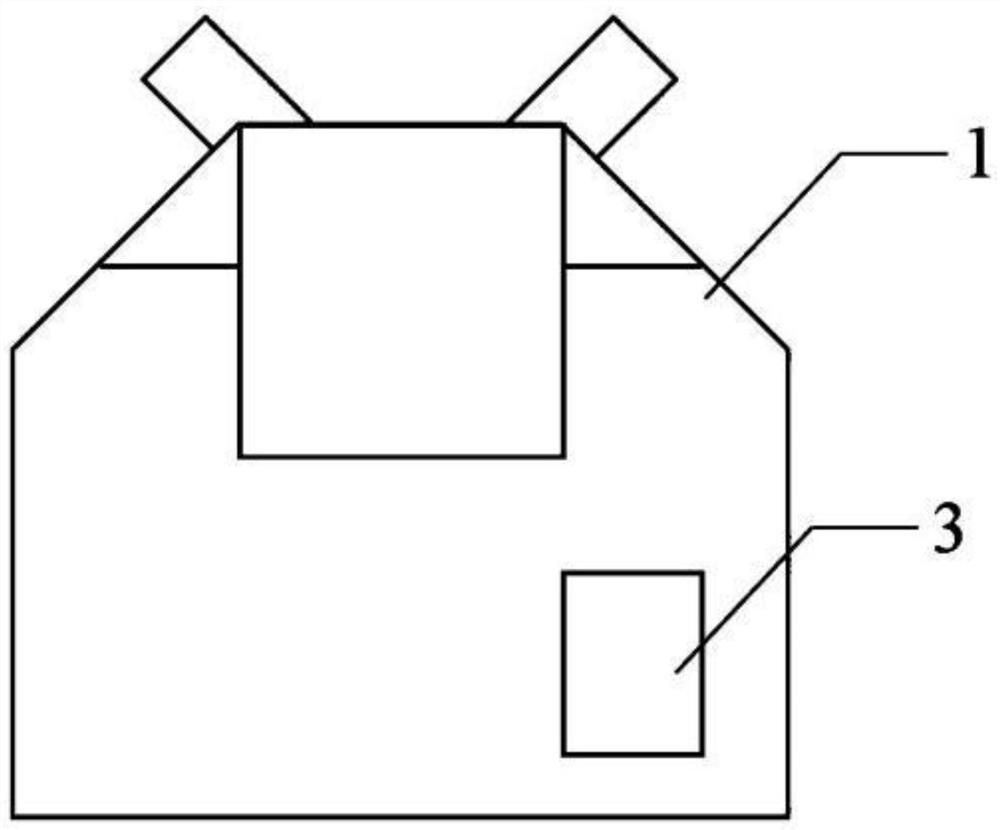

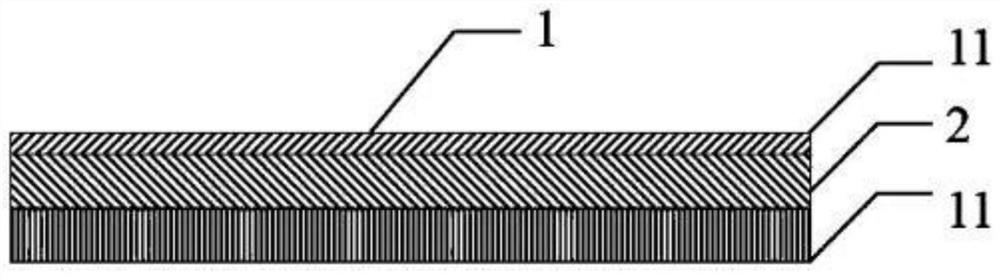

[0034] A windshield quilt with carbon nanofiber electric heating fabric, consisting of Figure 1~2 As shown, it includes a windshield quilt body 1 and an interlayer 2 arranged in the windshield quilt body; the windshield quilt body 1 includes two fabric layers 11, and an interlayer 2 is arranged between the two fabric layers 11; the interlayer 2 is made of carbon nanofiber electricity Made of heating fabric, carbon nanofiber electric heating fabric includes insulating fiber braid and carbon nanofiber material, wherein, the insulating fiber braid is woven from warp and weft, warp and weft are made of insulating fiber, carbon nanofiber material along The radial or weft direction of the insulating fiber braid is interspersed and arranged, the surface of the carbon nanofiber material is covered with an insulating and heat-conducting layer, the two ends of the carbon nanofiber material are connected to the electrodes, and the electrodes are connected to the power supply;

[0035] A...

Embodiment 2

[0052] A windshield quilt with carbon nanofiber electric heating fabric, consisting of Figure 1~2 As shown, it includes a windshield quilt body 1 and an interlayer 2 arranged in the windshield quilt body; the windshield quilt body 1 includes two fabric layers 11, and an interlayer 2 is arranged between the two fabric layers 11; the interlayer 2 includes an insulating fiber braid and carbon nanofiber material, wherein the insulating fiber braid is woven from insulating fibers through warp and weft, the carbon nanofiber material is interspersed along the radial or weft direction of the insulating fiber braid, and the surface of the carbon nanofiber material is coated There is an insulating and heat-conducting layer, the two ends of the carbon nanofiber material are connected to the electrodes, and the electrodes are connected to the power supply;

[0053] Among them, the carbon nanofiber material is prepared from high toughness carbon nanofibers.

[0054] The inner fabric laye...

Embodiment 3

[0070] A windshield quilt with carbon nanofiber electric heating fabric, consisting of Figure 1~2 As shown, it includes a windshield quilt body 1 and an interlayer 2 arranged in the windshield quilt body; the windshield quilt body 1 includes two fabric layers 11, and an interlayer 2 is arranged between the two fabric layers 11; the interlayer 2 includes an insulating fiber braid and carbon nanofiber material, wherein the insulating fiber braid is woven from insulating fibers through warp and weft, the carbon nanofiber material is interspersed along the radial or weft direction of the insulating fiber braid, and the surface of the carbon nanofiber material is coated There is an insulating and heat-conducting layer, the two ends of the carbon nanofiber material are connected to the electrodes, and the electrodes are connected to the power supply;

[0071] Among them, the carbon nanofiber material is prepared from high toughness carbon nanofibers.

[0072] The inner fabric laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com