Carbon fibre heating material and preparation method therefor

A heating material and carbon fiber technology, applied in fiber processing, heating element shape, fiber chemical characteristics, etc., can solve the problems of rising product cost, poor durability, and high production cost, and achieve freedom from equipment dependence, flexible voltage requirements, and heating temperature. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the invention will be described in detail with reference to the accompanying drawings of specific embodiments of the invention. The attached examples are intended to help understanding, and the invention should not be limited thereto. For those who have a certain understanding of the relevant knowledge in this field, the technologies that are clear or easy to understand at a glance will not be described in detail here.

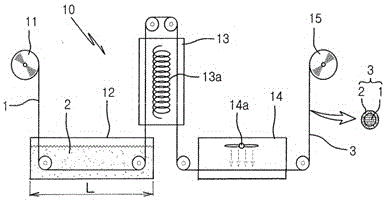

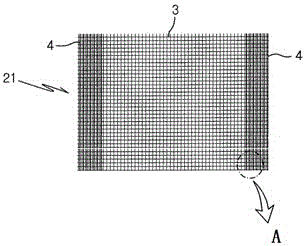

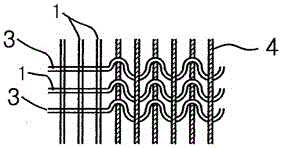

[0046] In order to achieve the above object, the present invention includes the following production stages. like figure 1 Shown is the manufacturing process of the planar heating element. That is, the synthetic fiber filaments, composite carbon fiber filaments are soaked in conductive paint, heated in a heating room at 300°C-500°C, and then placed in a cooling room equipped with a fan to cool to obtain the paint coating stage of the coated wire (10) Weaving the above-mentioned coated wire vertically and horizontally, and longitudinally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com