Method and apparatus for preparation of xylose and combined production of active carbon

A technology of activated carbon and xylose, applied in xylose production, sugar production, sugar production and other directions, can solve the problems of unfavorable process sustainable development, non-renewability, high economic cost, etc., achieve high environmental protection value, avoid pollution , the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

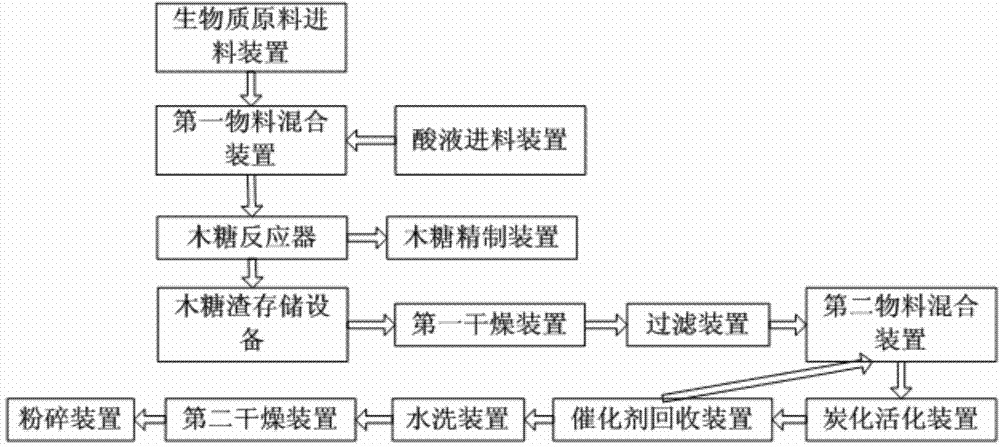

[0077] The equipment for preparing activated carbon for co-production of xylose provided by the present invention includes a biomass raw material feeding device, which is used for feeding biomass raw materials. In the present invention, the biomass raw material feeding device preferably includes a biomass raw material dust removal device and a biomass raw material crushing device, and the outlet of the biological raw material dust removal device is connected with the feed of the biological raw material crushing device, so The discharge port of the biomass raw material crushing device is connected with the first feed port of the first material mixing device. In an embodiment of the present invention, the biomass raw material is transported by a belt conveyor to the biomass raw material dedusting device to remove dust and sundries in the biological raw material; the dedusted biomass raw material flows into the biomass raw material Pulverize in the raw material crushing device to...

Embodiment 1

[0115] (1) Feeding and pretreatment of raw materials:

[0116] The corn cobs are sent to the receiving hopper of the feeding belt in the workshop, and then sent to the vibrating screening conveyor by the belt to screen out part of the sediment and debris before entering the washing machine. The corncob washing machine should regularly remove the sediment in its grit hopper. After washing, the corncobs are dehydrated through the vibrating dewatering screen and then enter the bucket elevator or the belt conveyor with a large inclination angle and sidewall, and then are lifted and transported to the horizontal belt conveyor on the top of the hydrolysis pot, and then sent to the needs through the chute controlled by the distribution plate. Load the hydrolysis pot.

[0117] (2) Hydrolysis:

[0118] During the hydrolysis process, the corncobs are first hydrolyzed and pretreated, and the corncobs are immersed in a sulfuric acid solution with a mass concentration of 0.1wt%±2wt%, and...

Embodiment 2

[0124] The technical scheme of Example 1 was used to prepare hydrolysis and activated carbon. The difference is that the acid solution used in the hydrolysis pretreatment in this example is an aqueous phosphoric acid solution with a mass concentration of 0.15 wt%, and the pretreatment temperature is 130°C. 1h; the acid solution used in the hydrolysis treatment is sulfuric acid with a mass concentration of 1%, and the temperature of the steam is 132°C.

[0125] The main components of the collected hydrolyzate are: xylose: 3-5%wt, arabinose: 0.3-0.55%wt, glucose: 0.45-0.65%wt, galactose: 0.15-0.3%wt, and the sugar concentration is generally 5-0.5%wt 8%wt.

[0126] In this example, the mass ratio of the absolute dry mass of xylose slag particles to pure phosphoric acid is 1:2.5, the temperature for carbonization activation is 490° C., and the time for carbonization activation is 80 minutes.

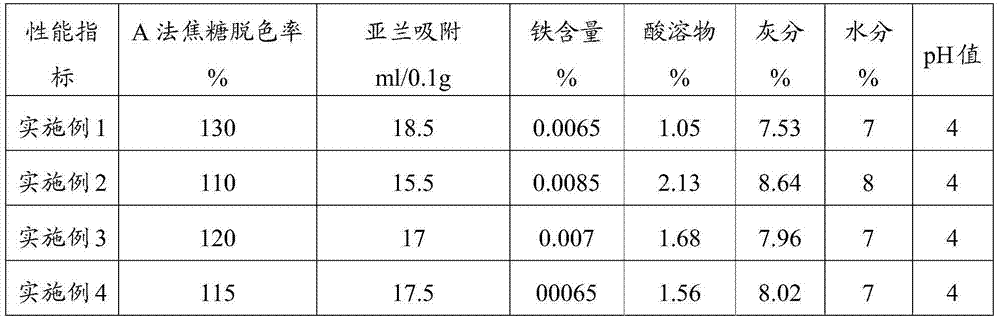

[0127] The present invention uses the test method described in Example 1 to test the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com