Propynylamine high-temperature acidizing corrosion inhibitor and preparation method thereof

A technology of acidifying corrosion inhibitor and propargyl amine, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve the problems of inconvenience in downstream production, and achieve short reaction time, low reaction temperature and low production cost. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

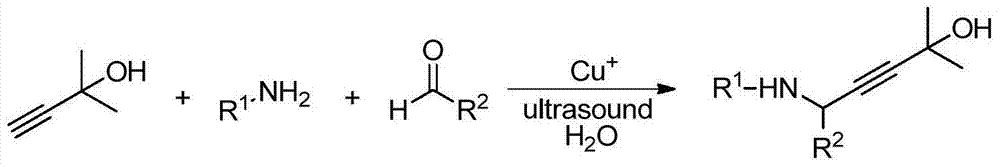

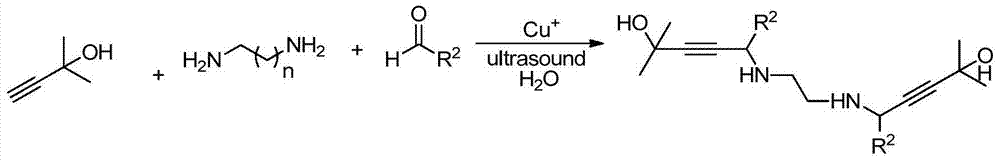

Method used

Image

Examples

Embodiment 1

[0033] Add 8.4g 2-methyl-3-butyn-2-ol, 7g n-butylamine, 5.8g propionaldehyde, 0.5g cuprous bromide, 5g potassium iodide, 10g octadecyl ammonium chloride into the reactor and dissolve In 80g of water, react in an ultrasonic cleaner at 25°C for 1 hour to obtain propargylamine high-temperature acidification corrosion inhibitor A.

Embodiment 2

[0035] Add 8.4g 2-methyl-3-butyn-2-ol, 3g ethylenediamine, 11g 40% acetaldehyde solution, 0.5g cuprous bromide, 5g potassium iodide, 10g octadecyl polyoxyethylene ether to the reaction and dissolved in 80g of water, and reacted for 1 hour in an ultrasonic cleaner at 25°C to obtain propargylamine high-temperature acidification corrosion inhibitor B.

Embodiment 3

[0037] Add 8.4g 2-methyl-3-butyn-2-ol, 3g ethylenediamine, 5.8.g propionaldehyde, 1g cuprous bromide, 5g potassium iodide, 10g cetyl ammonium chloride into the reactor and dissolve In 80g of water, react in an ultrasonic cleaner at 25°C for 1.5h to obtain propargylamine high-temperature acidification corrosion inhibitor C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com