Method for separating and extracting hyaluronic acid (HA) from rana chensinensis skins by using membrane filtration process

A hyaluronic acid and membrane filtration technology, which is applied in the field of separation and extraction of hyaluronic acid, can solve the problems of reagent residue, inability to effectively remove protein, and reduced safety, and achieve high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

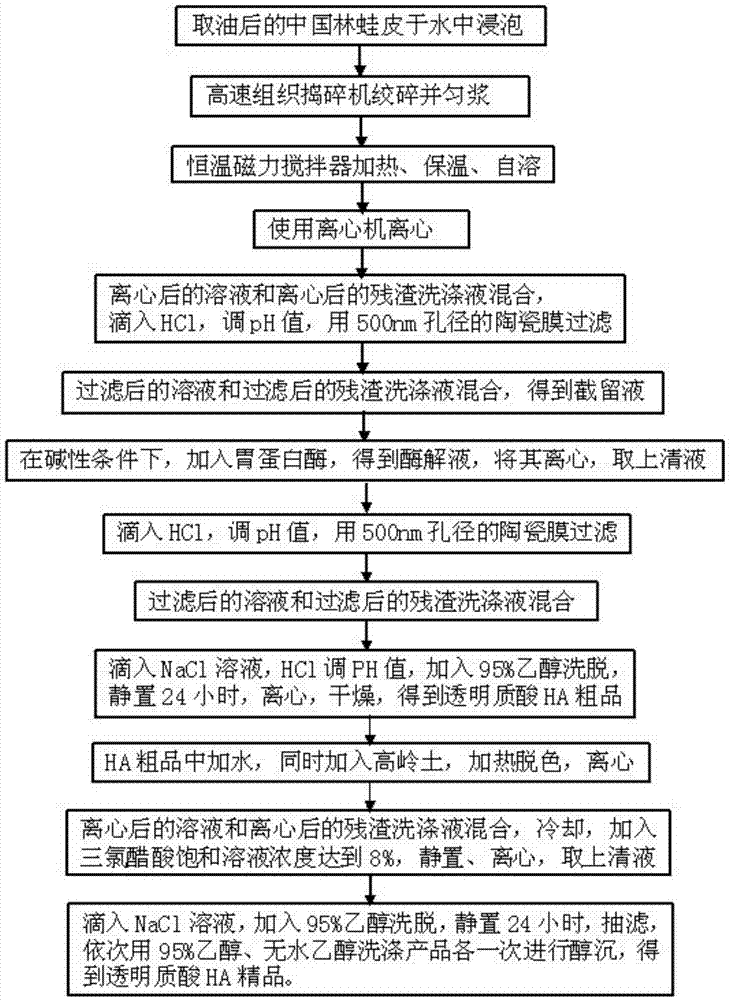

Image

Examples

Embodiment l

[0030] Embodiment 1, select the Chinese forest frog skin after getting the oil, the Chinese forest frog skin has a lower fat content, and is easily crushed, therefore, directly add 8 times the amount of water of the Chinese forest frog skin and soak for 20 hours. Homogenize at a speed of 10,000 rpm for 2 minutes, form a paste after homogenization, stir and heat to 85°C, keep warm for 5 minutes, cool to 45°C, autolyze for 12 hours, centrifuge at 4,000 rpm, add 4 times the amount of water, and divide Wash residue twice.

[0031] Adjust the pH to 1.5 with HCl, filter with a 500nm pore ceramic membrane, add 9 times the amount of water to wash with water 3 times, retentate, alkaline condition (pH7.5), pepsin (dosage: 45mg / g dry tissue) at 50°C for 12 hours, centrifuge the enzymolysis solution to get the clear liquid, adjust the pH to 1.5 with HCl, filter through a ceramic membrane with a pore size of 500nm, add 30 times the amount of water to wash with water 10 times, add NaCl to m...

Embodiment 2

[0033] Embodiment 2, select the Rana sinensis skin after oil extraction, the Rana sinensis skin has a low fat content and is easily crushed, therefore, directly add 10 times the amount of water of the Rana sinensis skin and soak for 24 hours. Homogenize at a speed of 12,000 rpm for 3 minutes, form a paste after homogenization, stir and heat to 90°C, keep warm for 10 minutes, cool to 50°C, autolyze for 12 hours, centrifuge at 4,000 rpm, add 4 times the amount of water, and separate Wash residue twice.

[0034]Adjust the pH to 2.0 with HCl, filter with a 500nm pore ceramic membrane, add 9 times the amount of water to wash with water 3 times, retentate, alkaline condition (pH8.5), pepsin (dosage: 40mg / g dry tissue) at 50°C for 12 hours, centrifuge the enzymatic solution to get the clear liquid, adjust the pH to 2.0 with HCl, filter with a 500nm pore size ceramic membrane, add 30 times the amount of water to wash with water 10 times, add NaCl to make the concentration of NaCl in t...

Embodiment 3

[0036] Embodiment 3, select the Rana sinensis skin after oil extraction, the Rana sinensis skin has a low fat content and is easy to grind, therefore, directly add 12 times the amount of Rana sinensis skin and soak in water for 28 hours. Homogenize at a speed of 14,000 rpm for 4 minutes, form a paste after homogenization, stir and heat to 95°C, keep warm for 15 minutes, cool to 55°C, autolyze for 12 hours, centrifuge at 4,000 rpm, add 4 times the amount of water, and separate Wash residue twice.

[0037] Adjust the pH to 2.5 with HCl, filter with a 500nm pore ceramic membrane, add 9 times the amount of water to wash with water 3 times, retentate, alkaline condition (pH8.0), pepsin (dosage: 50mg / g dry tissue) at 50°C for 12 hours, the enzymolysis solution was centrifuged to get the clear liquid, HCl was adjusted to PH2.5, 500nm pore size ceramic membrane was filtered, 30 times the amount of water was added to wash 10 times, NaCl was added to make the concentration of NaCl in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com