Gypsum material for 3D printing and preparation method thereof

A technology of 3D printing and gypsum materials, which is applied to 3D printing gypsum materials. In the field of preparation of gypsum materials, it can solve problems such as poor fluidity, low strength, and poor toughness, and achieve improved resolution, large specific surface area, and reduced printing. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of gypsum material for 3D printing is carried out according to the following steps:

[0036] According to the ratio of parts by mass, weigh 90-98 parts of hemihydrate gypsum, 1-10 parts of filler material, and 1-2 parts of fibers, and mix them thoroughly to form powder materials; according to the ratio of parts by mass, weigh 80-90 parts Parts of water, 5-15 parts of flexible bonding materials, 1-5 parts of coagulation materials, and fully dissolved by stirring and mixing to obtain liquid-phase materials; during 3D printing, 0.25-1 parts of liquid-phase materials are sprayed according to 1 part of powder material for molding .

Embodiment 1

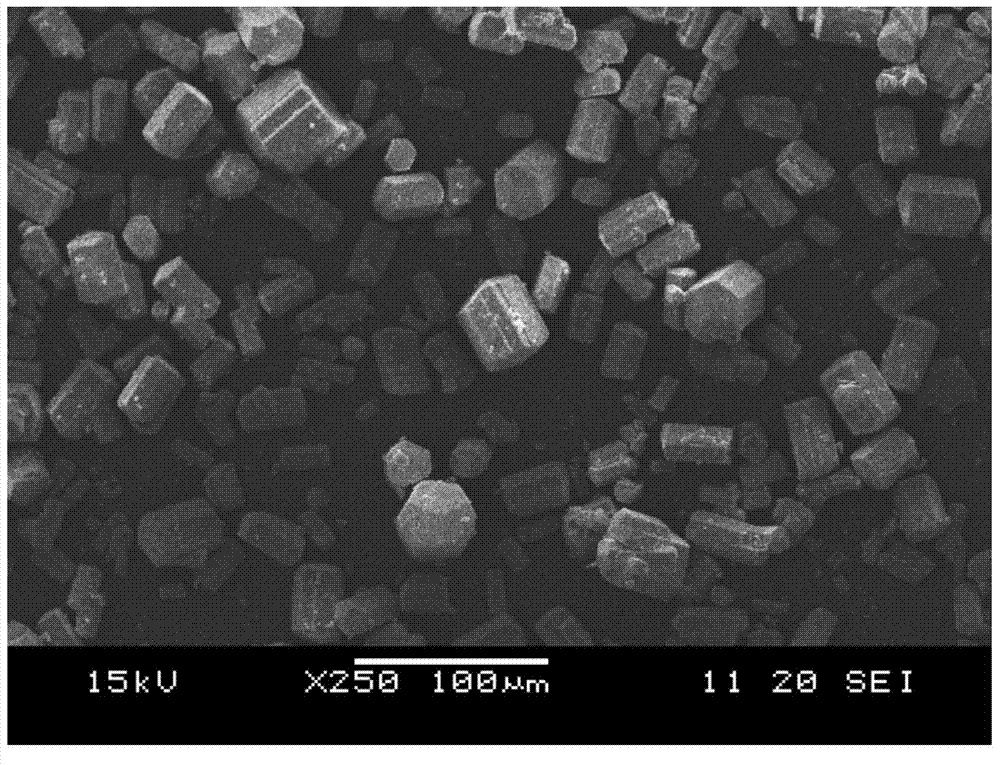

[0038] According to the ratio of parts by mass, weigh 95 parts of α-hemihydrate gypsum, 4.5 parts of limestone powder, and 0.5 part of glass fiber, wherein the aspect ratio of hemihydrate gypsum is 1:1.2, d0.5=25μm, limestone powder d0.5= 15μm, glass fiber length of 1mm, and then mixed to make powder materials; according to the ratio of parts by mass, weigh 85 parts of water, 5 parts of polyvinyl alcohol, 5 parts of hydroxypropyl methylcellulose, 5 parts of sodium sulfate, and stirred , Mixing and fully dissolving to obtain the liquid component material; the liquid material is sprayed onto the powder material by the 3D printer according to the ratio of 1 part of the liquid material to 2 parts of the powder material, and then large-scale gypsum products such as molds can be printed.

Embodiment 2

[0040] According to the ratio of parts by mass, weigh 98 parts of α-hemihydrate gypsum, 1 part of silica powder, and 1 part of lignocellulose, wherein the aspect ratio of hemihydrate gypsum is 1:1.5, d0.5=15 μm, silica Powder d0.5=10μm, lignocellulose length 1mm, and then mixed to make powder materials; according to the ratio of parts by mass, weigh 90 parts of water, 5 parts of redispersible latex powder, and 5 parts of calcium nitrate, after stirring and mixing Fully dissolve the liquid phase component material; the liquid phase material is sprayed onto the powder material by the 3D printer according to the ratio of 1 part of the liquid phase material to 4 parts of the powder material to print high-strength small gypsum models and molds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com