Hydrothermal synthesis method of zinc oxide nanomaterial and zinc oxide nanomaterial

A technology of hydrothermal synthesis and nanomaterials, applied in the direction of zinc oxide/zinc hydroxide, chemical instruments and methods, nanotechnology, etc., can solve the problems of low optical quality, high density, low growth rate, etc., to improve optical quality , simplification of operation steps, and the effect of reducing defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] According to the present invention, the hydrothermal synthesis method of the ZnO nanometer material comprises: under the condition of hydrothermal synthesis, contacting the reaction solution containing zinc salt and alkali with the growth substrate in a reaction kettle to obtain the ZnO nanomaterial on the growth substrate ZnO nanostructure array, wherein the reaction solution also contains ammonium salt.

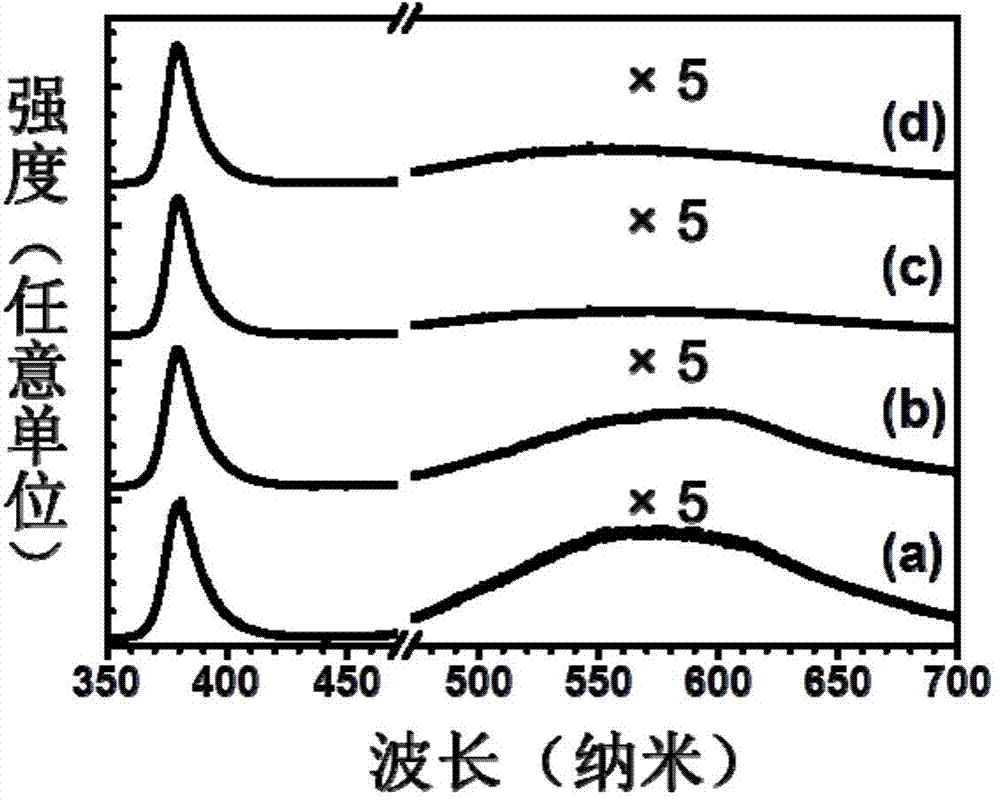

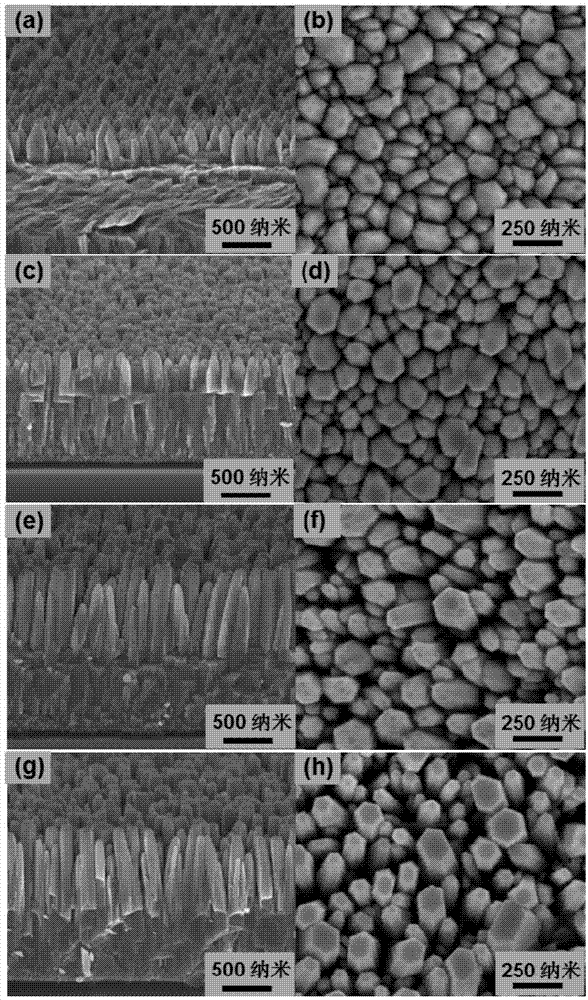

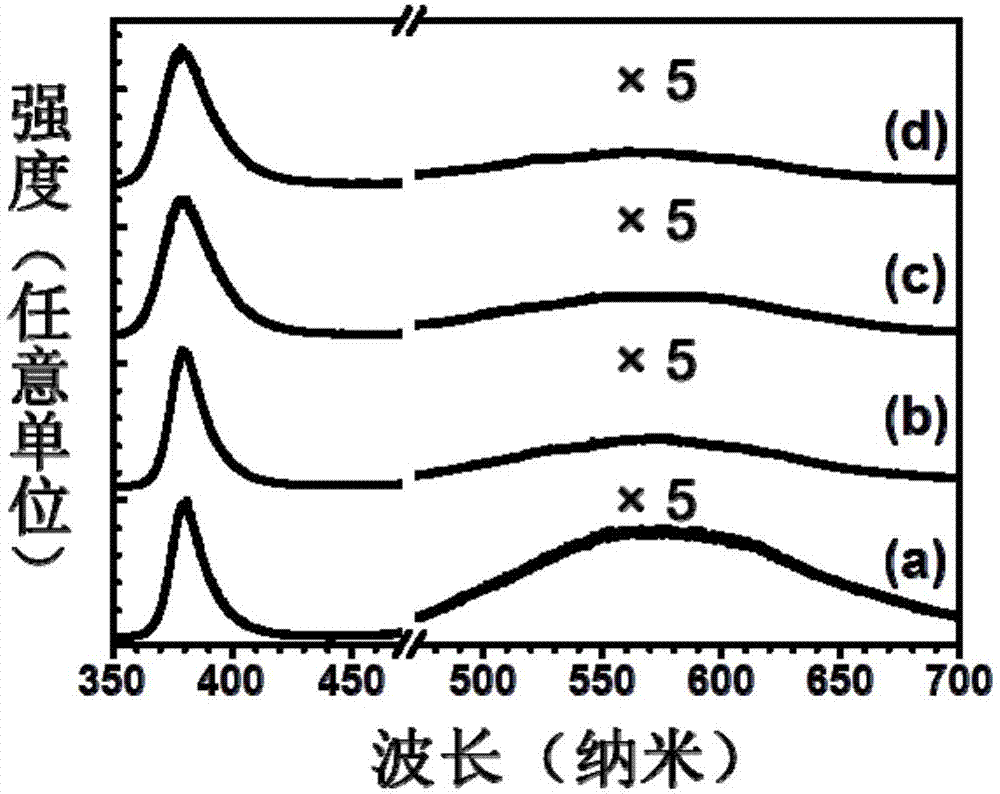

[0022] In the method of the present invention, by adding ammonium salt to the reaction solution containing zinc salt and alkali, the defect density of the ZnO nanostructure synthesized by this hydrothermal method is significantly reduced, and the length is significantly increased under the same growth time, thereby greatly improving The optical quality and growth rate of the ZnO nanostructure arrays were investigated.

[0023] According to the present invention, the type of the ammonium salt can be selected from a wide range, preferably, the ammonium salt is selected...

Embodiment 1-3

[0038] This example is used to illustrate the synthesis method of the zinc oxide nanomaterial provided by the present invention.

[0039] The aluminum-doped zinc oxide (AZO) transparent conductive film glass as the growth substrate was cleaned in an ultrasonic bath of organic solvents (acetone and ethanol), and then ultrasonically cleaned with water.

[0040] Dissolve zinc acetate (0.005M) and hexamethylenetetramine (0.005M) with a molar ratio of 1:1 in water, ultrasonically dissolve and mix evenly to prepare a mixed solution, and add different concentrations of ammonium nitrate to it, ultrasonically Dissolve and mix evenly, the concentrations of ammonium nitrate in the aqueous solution are 0.01M, 0.05M and 0.1M respectively, and the molar ratios of ammonium nitrate and zinc acetate are 2:1, 10:1 and 20:1 respectively.

[0041] Put the above growth substrate into a reaction kettle containing a mixed solution containing zinc salt, alkali and ammonium salt, put the reaction kett...

Embodiment 4-6

[0052] This example is used to illustrate the synthesis method of the zinc oxide nanomaterial provided by the present invention.

[0053] The aluminum-doped zinc oxide (AZO) transparent conductive film glass as the growth substrate was cleaned in an ultrasonic bath of organic solvents (acetone and ethanol), and then ultrasonically cleaned with water.

[0054] Dissolve zinc acetate (0.005M) and hexamethylenetetramine (0.005M) with a molar ratio of 1:1 in water, ultrasonically dissolve and mix evenly, and prepare a mixed solution, and add different concentrations of ammonium acetate to it, ultrasonically Dissolve and mix evenly, the concentrations of ammonium acetate in the aqueous solution are 0.04M, 0.05M, and 0.08M, and the molar ratios of ammonium acetate to zinc acetate are 8:1, 10:1, and 16:1, respectively.

[0055] Put the above growth substrate into a reaction kettle containing a mixed solution containing zinc salt, alkali and ammonium salt, put the reaction kettle into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com