Lifting rack random locking mechanism of truss pile leg platform

A technology of platform lifting and locking mechanism, applied in the direction of lifting frame, lifting device, etc., can solve the problems of serious tilting of the platform, loss of locking function, platform sliding, etc., and achieve the effect of improving safety, convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

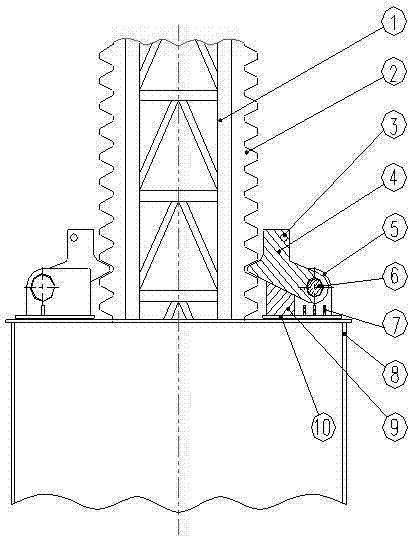

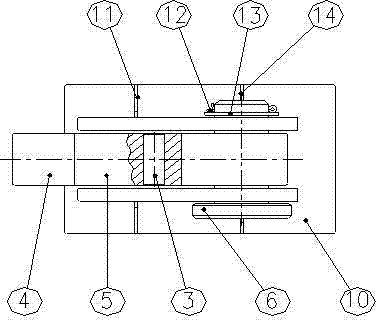

[0020] Reference truss leg platform lifting rack random locking mechanism structure figure 1 , figure 2 The narration of the embodiment of the simplified scheme is shown as follows:

[0021] A truss leg platform lifting rack random locking mechanism, the rack 2 is fixed on the platform lifting pile 1; the front end of the pawl 4 is processed with a pawl shape, and is engaged with the rack; the rear end of the pawl 4 passes through the Claw pin shaft 6 hinges on the pin shaft main force plate 5, and the pin shaft main force plate 5 is fixed on the pile area 8.

Embodiment 3

[0023] On the basis of the above-mentioned embodiment 2, the front end of the pawl 4 is equipped with a gravity block, and the upper end of the gravity block is provided with a force hole 3 .

[0024] The seat pier 9 is provided below the ratchet device 4 ; the upper surface of the seat pier 9 is provided with a slope matching the pawl device 4 ;

[0025] For the specific applications of the above-mentioned embodiments 2 and 3, refer to the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com