A device for reducing liquid sloshing in moon pools of marine engineering structures

A technology for marine engineering and structures, which is applied in the field of devices for reducing liquid sloshing in the moon pool of drilling ships or drilling platforms, and devices for reducing the swaying of structures in marine engineering, can solve problems such as affecting the propulsion efficiency of ships, and improve water quality. Dynamic performance, stopping waves from climbing, reducing the effect of coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

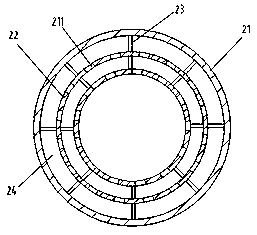

[0027] Such as figure 1 with figure 2 As shown, this embodiment includes a guide cover 2 fixed on the inner wall 1 of the moon pool. The guide cover 2 is a cylindrical structure with a double-layer shell, and includes an outer shell that is fixedly connected with the inner wall 1 of the moon pool. 21. The inner shell 22, a plurality of vertical ribs 23 and a plurality of arc-shaped transverse ribs 24, the outer shell 21 and the inner shell 22 are all in the shape of a horn with a small top and a big bottom matching the shape of the moon pool 1 shape, reduce wave climb, prevent deck 3 from overflowing, and ensure the safety of staff on deck 3. The inner shell 22 is arranged between the outer shell 21 and the inner wall 1 of the moon pool, and a plurality of vertical ribs 23 are uniformly distributed in the radial direction between the outer shell 21, the inner shell 22 and the inner wall 1 of the moon pool, vertically The ribs 23 are made of I-shaped steel, which improves th...

Embodiment 2

[0029] Such as Figure 3 ~ Figure 5 As shown, this embodiment includes multiple layers of wave breaking rings 4 arranged parallel to the axis of the moon pool and having the same inner hole size. The wave breaking ring 4 is a hollow ring structure, including an upper ring plate 41 and a lower ring plate 43 arranged in parallel. and the base ring plate 42 in the middle, and three ring rib plates 44 respectively fixed between the upper ring plate 41, the base ring plate 42 and the lower ring plate 43, the upper ring plate 41, the lower ring plate 43 and the base ring plate 42 The diameter of the rim matches the shape of the moon pool; the outer diameters of the wave-dissipating rings 4 of each layer increase gradually from the deck 3 to the bottom 5 of the ship, and the outer edges of the wave-eliminating rings 4 of each layer are welded and fixed to the inner wall 1 of the moon pool respectively. The inner hole of the upper ring plate 41, the inner hole of the base ring plate a...

Embodiment 3

[0031] Such as Figure 6 ~ Figure 8 As shown, this embodiment includes several rows of arc-shaped wave-dissipating plates 5 arranged at intervals along the inner wall of the moon pool 1 in layers and in opposite helical directions. The inner side of the arc-shaped wave-dissipating plate 5 is welded and fixed on the inner wall 1 of the moon pool. In order to improve the strength of the arc-shaped wave-dissipating plate 5, a plurality of ribs 52 are respectively arranged between the upper and lower sides of the arc-shaped wave-dissipating plate 5 and the inner wall 1 of the moon pool. , the arc-shaped wave-dissipating plate 5 is provided with several rows of wave-dissipating plate lightening holes 51 arranged at intervals in the radial direction, and the hemispherical shell 6 is respectively fixed on both sides of the wave-plate lightening holes 51 symmetrically up and down. The helix angle of the arc-shaped wave-dissipating plate 5 is α=30°, the distance between the arc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com