Frame cross member welding

A frame beam and welding technology, applied in the field of fixed frames, can solve problems such as hidden safety hazards, difficult installation and maintenance, etc., and achieve the effect of solving hidden safety hazards and difficult installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

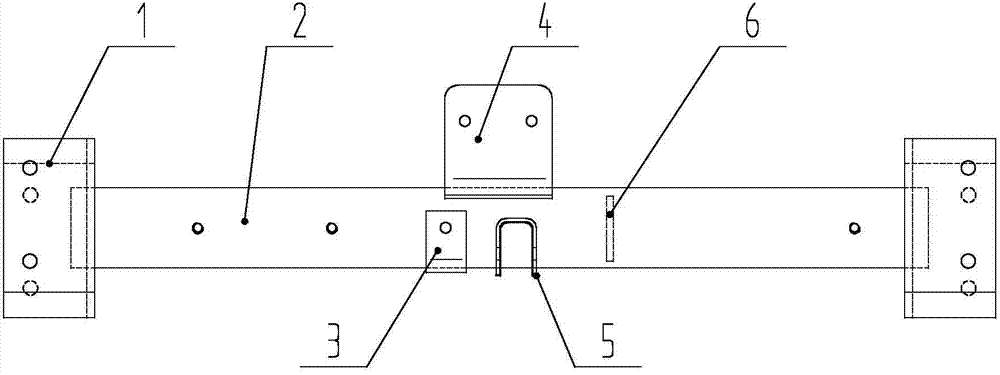

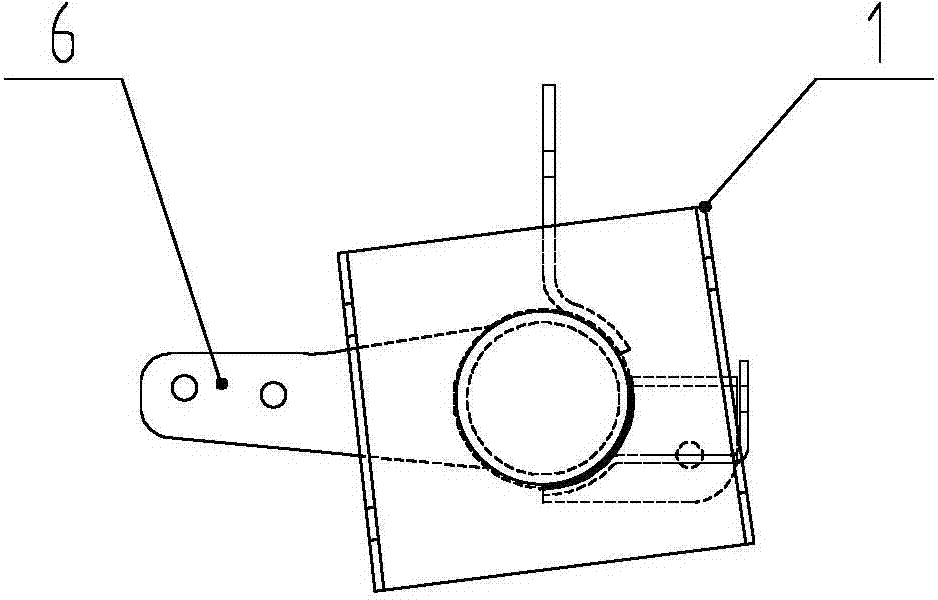

[0010] like figure 1 , 2 As shown, the present invention includes a beam tube 2, which is characterized in that a beam fixing plate 1 is provided at both ends of the beam tube 2, a flameout motor mounting plate 4 is provided above the middle of the beam tube 2, and a flameout motor mounting plate 4 is shown The front side of the lower left crossbeam tube 2 is provided with a steering tubing bracket 3, the right side of the steering tubing bracket 3 is provided with a water tank strut bracket 5, and the right side of the water tank strut bracket 5 is provided with a horn bracket 6 on the rear side of the crossbeam tube 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com