Nail head device for nailing corrugated board and box nailing machine

A corrugated cardboard and nailing machine technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve the problem of unsteady up and down displacement of cutters and dies, and achieve compact structure, high nailing efficiency, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

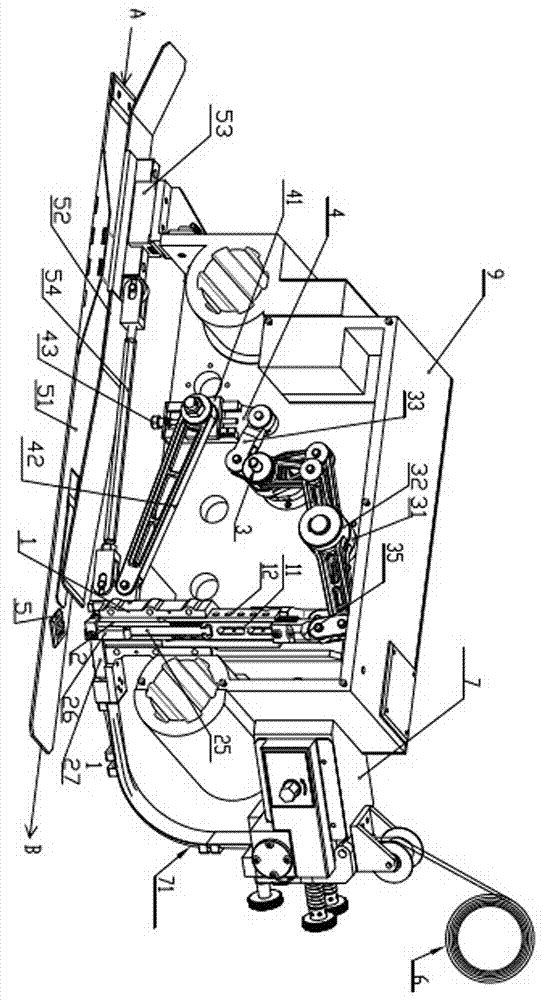

[0023] Aiming at the above-mentioned technical solution, a preferred embodiment is given and described in detail with reference to the drawings. The nail box machine of the present invention mainly includes a driving device, a nail head device and a wire feeding device, see Figure 1~Figure 6 ,in.

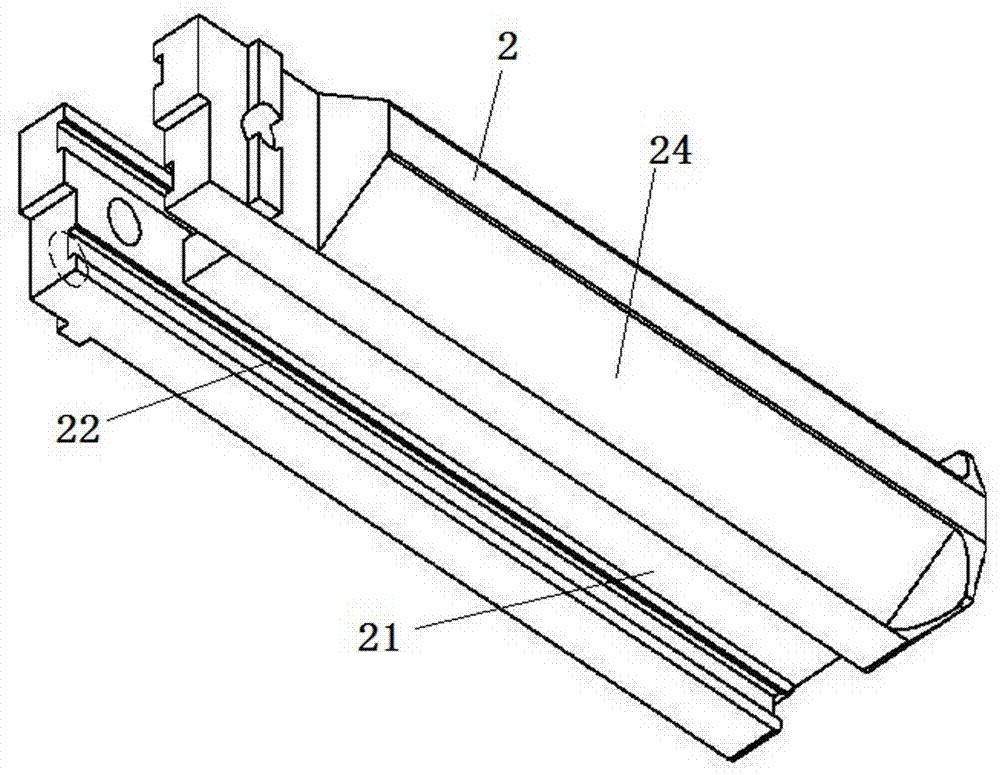

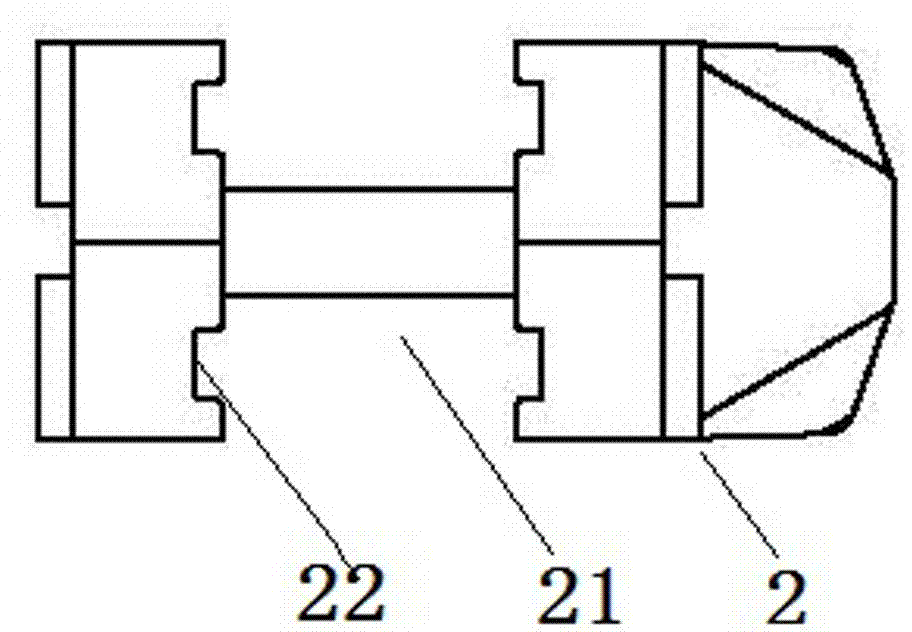

[0024]Nail head device comprises nail head frame 1, and nail head frame 1 is a hollow structure, and vertical front, rear, left and right four slide rails are fixedly set in nail head frame 1, and front and rear slide rails and left and right slide rails are parallel to each other. On each slide rail, be provided with the slide block that can displace up and down along the slide rail, the slide block on the front and rear slide rails is the punch slide block 11, and the slide block on the left and right slide rails is the cutter slide block 12. The left and right upper ends of the cutter device 2 are respectively fixed on the lower ends of the left and right sliders. Cutter devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com