A kind of forging method of Cu-containing nickel-based alloy and Cu-containing nickel-based alloy

A technology of nickel-based alloy and forging ratio, which is applied in the field of forging technology to achieve fine and uniform microstructure, improve the structure and improve the performance of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

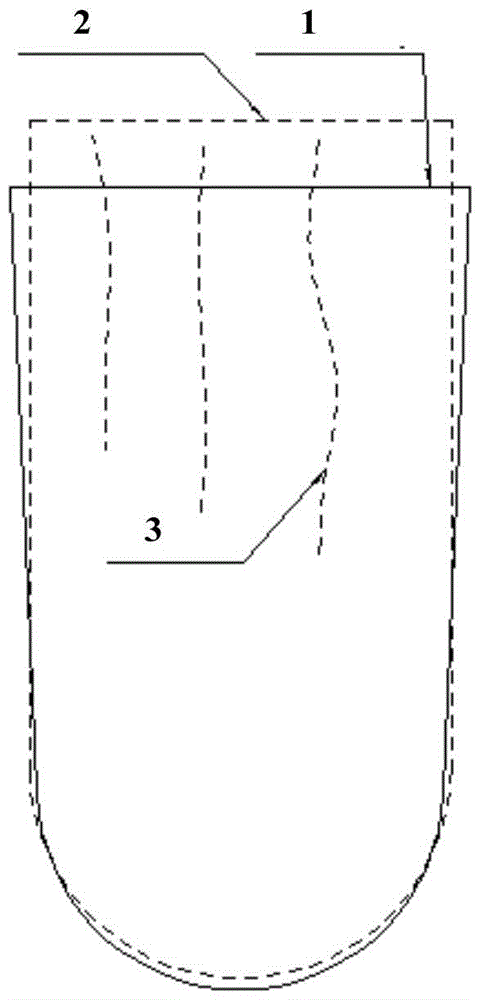

Image

Examples

Embodiment 1

[0063] Melting in a 25kg vacuum induction furnace Cu-containing nickel-based alloy ingot, the composition of the ingot is Cu-Ni-Cr-Fe, and the height of the riser is 103mm. The ingot is forged on a 0.7T free forging hammer. The specific operation steps are as follows:

[0064] Pretreatment: Grinding the surface of the ingot to remove defects such as subcutaneous air bubbles, spatters and scale on the surface.

[0065] Open billet forging: heat the pretreated ingot to 1120±10°C with the furnace and keep it warm for 2.5 hours, then take it out of the furnace for forging, the initial forging temperature is 1061°C, the final forging temperature is 908°C, and the cross-sectional size of 112mm×105mm square billet, the forging ratio is 1.25;

[0066] Preliminary forming: return the above forged billet with a cross-sectional size of 112mm×105mm to the furnace, heat it to 1080±10°C and keep it warm for 1 hour, then take it out of the furnace for forging, the initial forging temperatu...

Embodiment 2

[0070] Melting in a 25kg vacuum induction furnace Cu-containing nickel-based alloy ingot, the composition of the ingot is Cu-Ni-Cr-Fe, and the height of the riser is 97mm. The ingot is forged on a 0.7T free forging hammer. The specific operation steps are as follows:

[0071] Pretreatment: Grinding the surface of the ingot to remove defects such as subcutaneous air bubbles, spatters and scale on the surface.

[0072] Open billet forging: heat the pretreated ingot to 1120±10°C with the furnace and keep it warm for 2.5 hours, then take it out of the furnace for forging, the initial forging temperature is 1058°C, the final forging temperature is 913°C, and the cross-sectional size of 113mm×108mm square billet, the forging ratio is 1.30;

[0073] Preliminary forming: Return the above forged billet with a cross-sectional size of 113mm×108mm to the furnace, heat it to 1080±10°C and keep it warm for 1 hour, and then take it out of the furnace for forging. A flat ingot with a size ...

Embodiment 3

[0077] Melting in a 25kg vacuum induction furnace Cu-containing nickel-based alloy ingot, the composition of the ingot is Cu-Ni-Cr-Fe, and the height of the riser is 98mm. The ingot is forged on a 0.7T free forging hammer. The specific operation steps are as follows:

[0078] Pretreatment: Grinding the surface of the ingot to remove defects such as subcutaneous air bubbles, spatters and scale on the surface.

[0079] Open billet forging: heat the pretreated ingot to 1120±10°C with the furnace and keep it warm for 2.5 hours, then come out of the furnace for forging, the initial forging temperature is 1062°C, the final forging temperature is 911°C, and the cross-sectional size of 115mm×104mm square billet, the forging ratio is 1.19;

[0080] Preliminary forming: Return the above forged billet with a section size of 115mm×104mm to the furnace, heat it to 1080±10°C and keep it warm for 1 hour, then take it out of the furnace for forging, the initial forging temperature is 1030°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com