Processing equipment for horn mouth of metal tube

A technology for processing equipment and metal pipes, which is applied in the field of bell mouth processing equipment, can solve the problems of complicated processing procedures, frequent switching of processing parts, and reduced processing efficiency, so as to reduce the probability of defective products, reduce parts, and improve production efficiency. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

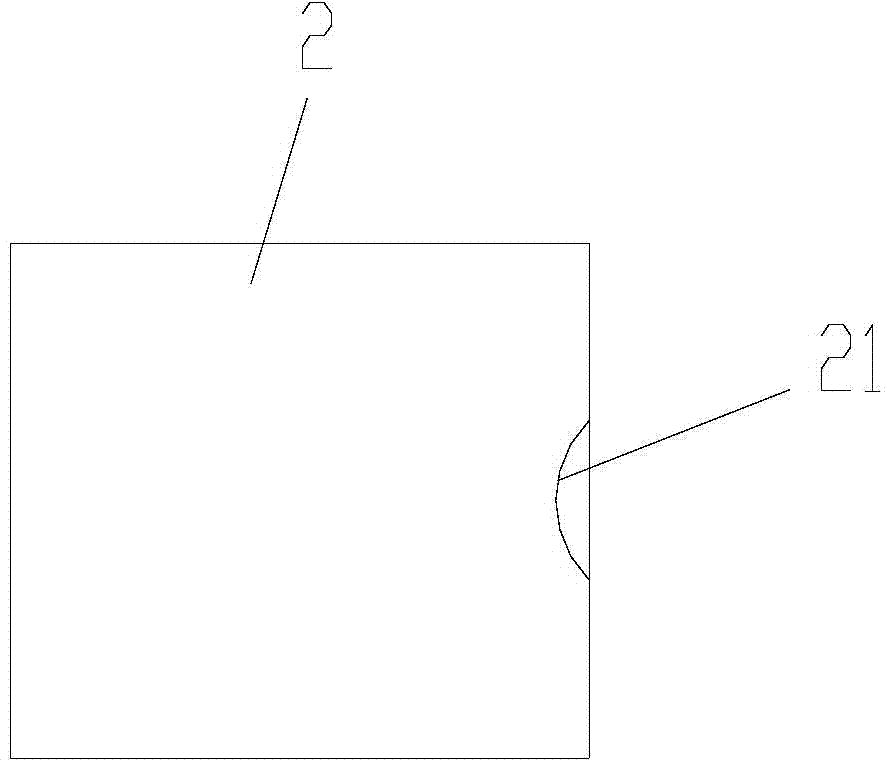

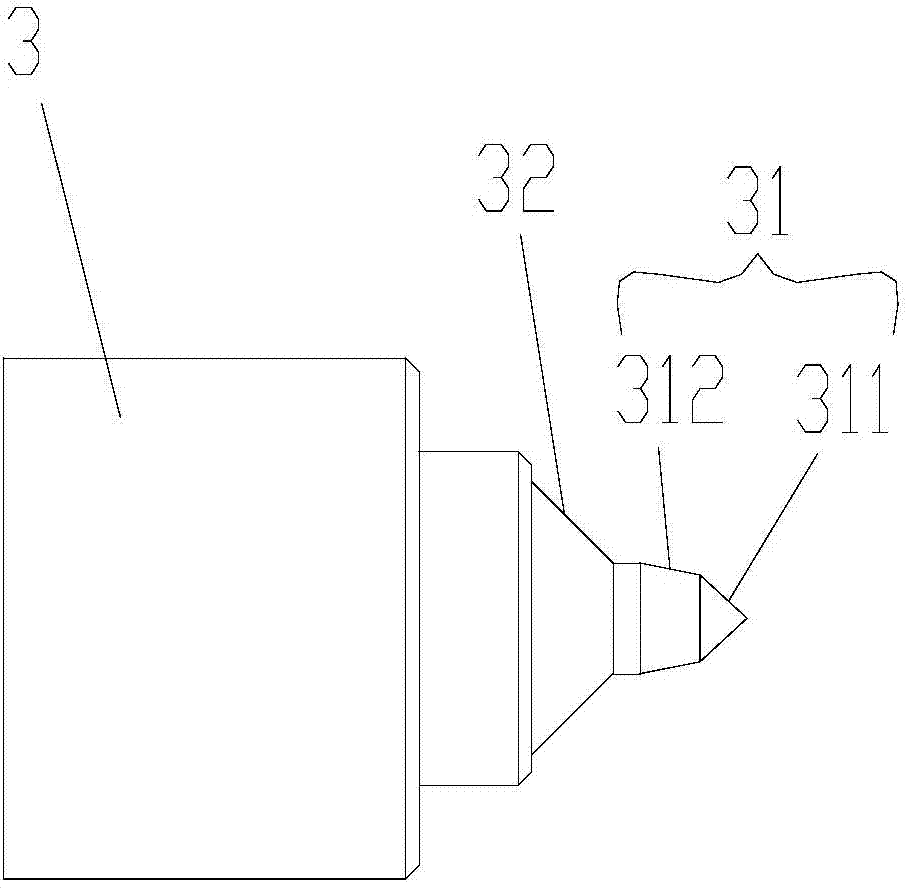

[0016] see Figure 1 to Figure 3 , a metal pipe bell mouth processing equipment, used for processing the bell mouth of the connecting pipe of the internal and external units of the air conditioner, especially for the connecting pipe made of copper alloy. It includes a fixing device 1 , a shrinking punch 2 and a flared punch 3 .

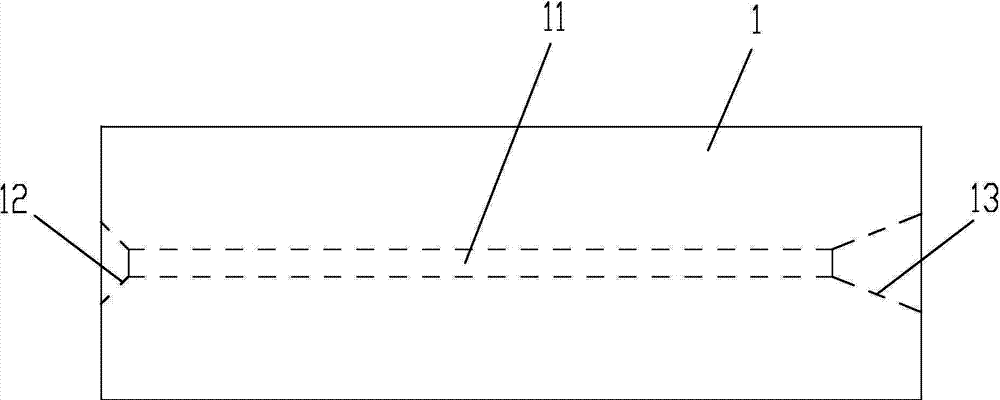

[0017] see figure 1 , The fixing device 1 is assembled from two parts, with a clamping space 11 for clamping the metal pipe in the middle, and the front part of the fixing device 1 has a tapered groove 12 exposing the front end of the metal pipe after the two parts are put together. In order to facilitate the manual operation of the metal pipe and adjust the exposed length of the front end of the metal pipe, the rear part of the fixing device 1 has a tapered groove 13 that exposes the rear end of the metal pipe.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com