Magnetic zeolite, and preparation method and application thereof

A technology of magnetic zeolite and zeolite powder, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as high production costs and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of magnetic zeolite

[0032] Use a ball mill to grind the purchased zeolite particles for 10 minutes, pass the ground zeolite through 80 mesh and 300 mesh sieves, take the zeolite in the middle of the two sieves, soak it in a beaker with 0.1M dilute hydrochloric acid, and put it in an ultrasonic cleaner for 30 minutes. , Pour the supernatant into the waste liquid bottle, rinse the sediment with deionized water 3 times and then dry it for later use.

[0033] Take 5.0 grams of zeolite after cleaning and drying, add it to a 400mL beaker, and weigh 6.66 grams of FeCl 3 ·7H 2 O, 3.66 g FeSO 4 ·6H 2 Add O to the beaker and add 200 mL of deionized water.

[0034] Place the beaker on a magnetic stirrer with heating function, and heat it while stirring. Place the thermometer on the inner wall of the beaker with a transparent tape to monitor the temperature, heat it to 65°C, and stop heating.

[0035] Transfer the beaker to an unheated magnetic stirrer, continue sti...

Embodiment 2

[0047] Example 2 Preparation of magnetic zeolite

[0048] Use a ball mill to grind the purchased zeolite particles for 10 minutes, pass the ground zeolite through 80 mesh and 300 mesh sieves, take the zeolite in the middle of the two sieves, soak in 0.1M dilute hydrochloric acid for 1 hour, and neutralize the supernatant with calcium carbonate powder Then pour it into the sewer. Rinse the zeolite 3 times with tap water and dry it for later use.

[0049] Take 5.0 kg of cleaned and dried zeolite, add it to a 200L galvanized iron bucket or a stainless steel container, add 6.66 kg of ferric chloride heptahydrate, 3.66 kg of ferrous sulfate hexahydrate, and then add 100L of tap water.

[0050] Set up a blade stirrer on the top of the iron barrel for mixing, set up a thermometer for the temperature of the liquid in the barrel, and then heat it to 70°C on an electric furnace, and stop heating.

[0051] Continue to stir until the temperature drops below 40°C.

[0052] A pH meter is added to t...

Embodiment 3

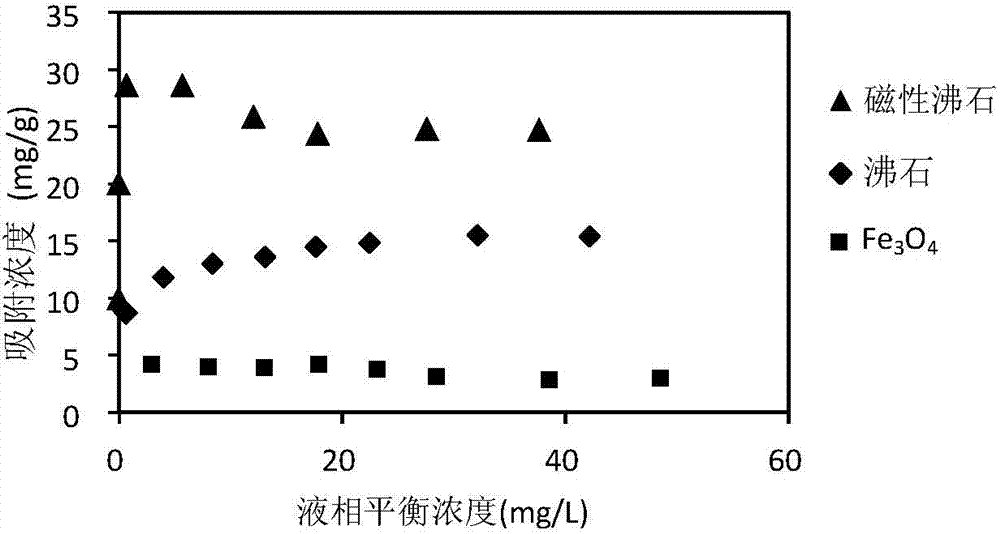

[0063] Example 3 Using the prepared magnetic zeolite to adsorb and remove Pb in sewage 2+

[0064] Add 20mg Pb(NO 3 ) 2 , 250mL deionized water, formulated into Pb 2+ Artificial sewage with a concentration of 50 mg / L.

[0065] Add 125 mg of the magnetic zeolite prepared in Example 2 to the Erlenmeyer flask, seal it with a sealing film, and place it on a horizontal shaker for 24 hours;

[0066] Place the Erlenmeyer flask on a magnet, so that the magnetic zeolite in the flask will rapidly precipitate. Use a 15mL syringe to draw the supernatant, filter it with a 0.45 micron filter membrane, pour it into a 20mL plastic bottle, and measure Pb by ICP-AES 2+ Ion concentration.

[0067] Test result, Pb in supernatant 2+ The ion concentration is 2.51mg / L, and the removal rate is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com