Extraction system and extraction method of coal liquefaction residue

A coal liquefaction residue and extraction technology, which is applied in the field of extraction system of coal liquefaction residue, can solve problems such as complex extraction process, and achieve the effect of overcoming complex process, efficient extraction and separation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

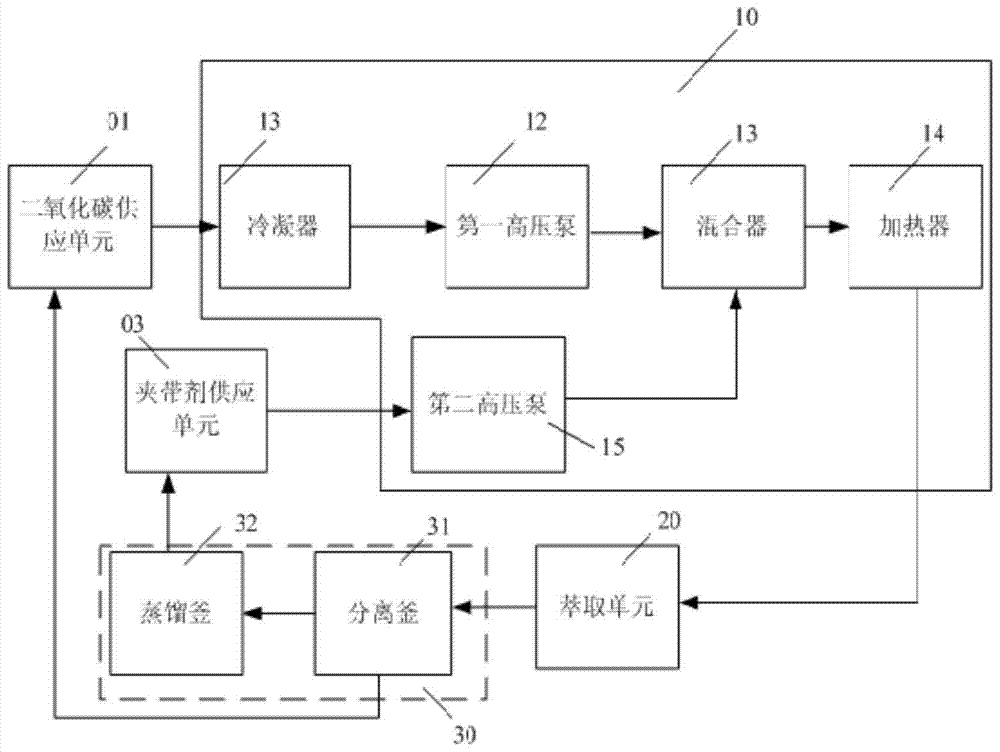

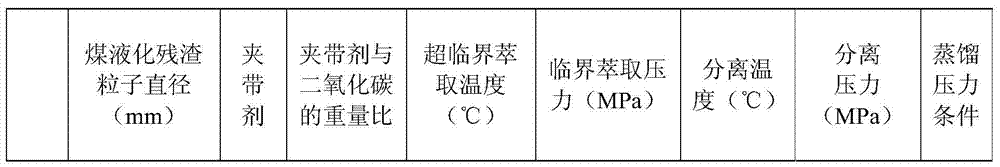

[0049] The specific process conditions of extraction are shown in Table 1. use figure 2 The extraction system shown extracts coal liquefaction residue, takes 500 kg of coal liquefaction residue particles with a particle size of 0.2-1.0 mm, puts them into the extraction unit 20 and seals them. Control the carbon dioxide in the carbon dioxide supply unit 01 to enter the heater 14 through the carbon dioxide condenser 11 and the first high-pressure pump 12 at a flow rate of 20 L / h, and the heater 14 heats the mixture from the above-mentioned mixer 13 to further ensure that the carbon dioxide is in a supercritical state.

[0050] Send the carbon dioxide in the heater 14 into the extraction unit 20, the pressure in the extraction unit 20 is 30MPa, and the temperature is 60°C, and the coal liquefaction residue is extracted in the extraction unit 20 to obtain an extract, which contains supercritical A mixture of carbon dioxide fluid and heavy liquefied oil.

[0051] The extract ent...

Embodiment 2

[0053] The specific process conditions of extraction are shown in Table 1. use figure 2 The shown extraction system extracts coal liquefaction residue, takes 500 kg of coal liquefaction residue particles with a particle size of 1.2-2.0 mm, puts them into the extraction unit 20 and seals them. Control the weight ratio of n-hexane and carbon dioxide to be 10:100, carbon dioxide enters the mixer 13 through the carbon dioxide condenser 11, the first high-pressure pump 12, and the n-hexane in the entrainer supply unit 03 enters the second high-pressure pump 15 for pressurization, Then the second high-pressure pump 15 feeds n-hexane as an entrainer into the mixer 13 . The heater 14 heats the mixture from the above-mentioned mixer 13 to further ensure that the carbon dioxide is in a supercritical state.

[0054] Send n-hexane and carbon dioxide in the heater 14 with a weight ratio of 10:100 to the extraction unit 20, the pressure in the extraction unit 20 is 30MPa, and the tempera...

Embodiment 3

[0057] The specific process conditions of extraction are shown in Table 1. use figure 2 The extraction system shown extracts the coal liquefaction residue, and the weight and extraction rate of the obtained heavy liquefied oil are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com