High spandex strong anti-slip chemical fiber double-sided fabric and preparation method thereof

A high-strength spandex technology, applied in the textile field, can solve the problems of poor hygroscopicity, small modulus, and resistance to oxidation of spandex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0046] The raw material composition of embodiment 1-5 is as shown in table 1:

[0047] Table 1.

[0048]

[0049] Embodiment 1-5 is all prepared according to the following method:

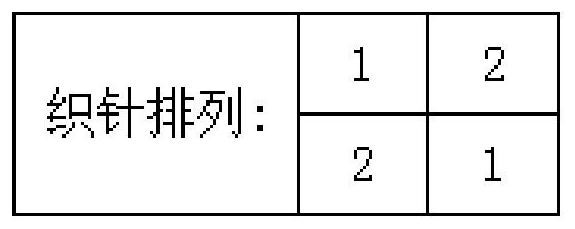

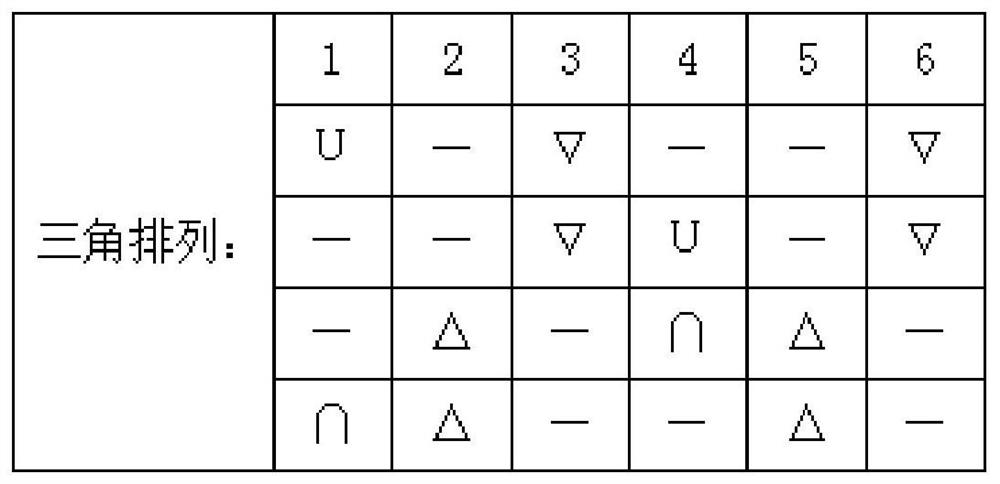

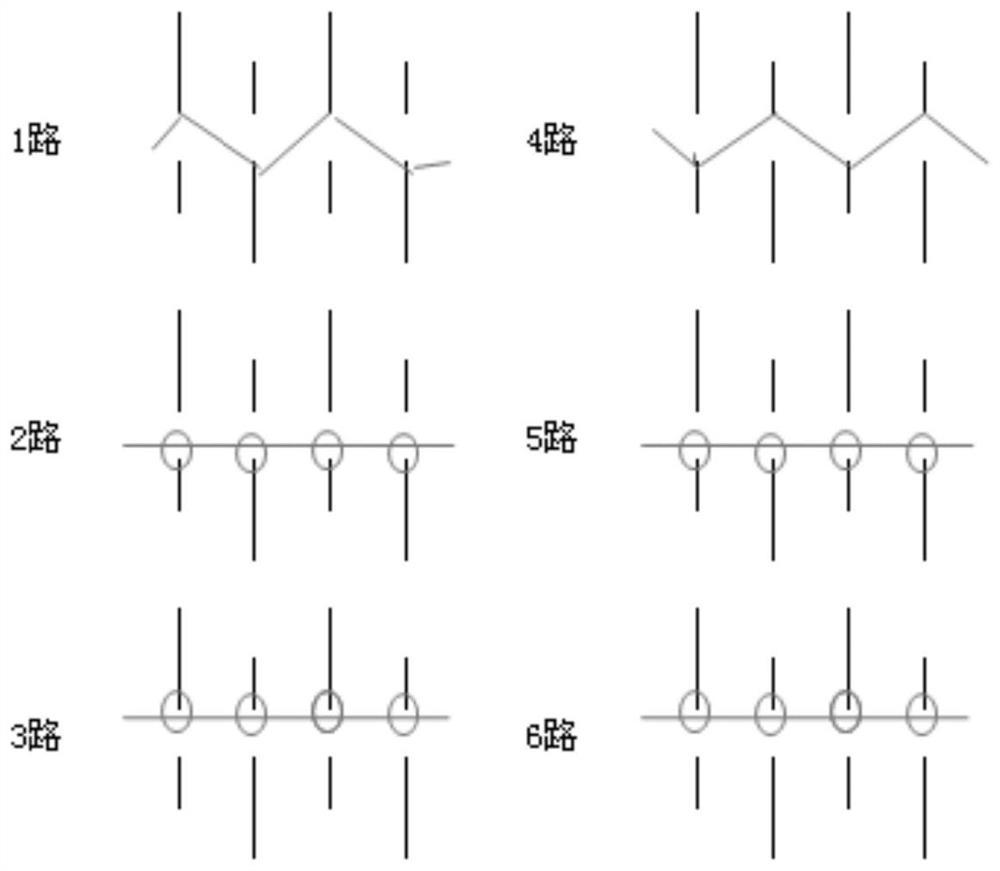

[0050] (1) Double-needle bed machine is used for weaving, and the number of incoming lines of the machine is 72, and the number of incoming lines of 6 lines is one cycle. Among them, the first and fourth lines are used for weaving with PU 70D, and the second and fifth lines are used for weaving. Wear PA6 40D / 34F SD DTY plus padded spandex PU140D for weaving on one side, and wear PU 140D on one side for three-way and six-way weaving;

[0051] (2) The roll cloth seal on the machine is controlled at 147CM, the warp density on the machine is 27 lines / CM, and the machine speed is controlled at 13 rpm;

[0052] (3) The incoming raw materials of each route are fed into the loop forming system through the yarn guide device to weave into loops, and the tension of each incoming thread of the same raw ma...

Embodiment 6-7

[0058] Embodiment 6-7, comparative example 1-5

[0059] The raw material composition of Examples 6-7 and Comparative Examples 1-5 is the same as that of Example 1, and the different process parameters in the preparation process are shown in Table 2, and the rest are the same.

[0060] Table 2.

[0061]

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com