Method for subcritical fluid extraction of tea extract

A technology of subcritical fluid and tea extract, applied in the direction of tea extraction, etc., can solve the problems of destruction of tea bioactive components, high cost of production equipment, unfavorable treatment of tea dregs, etc., achieve good reuse, lower production conditions, and lower costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

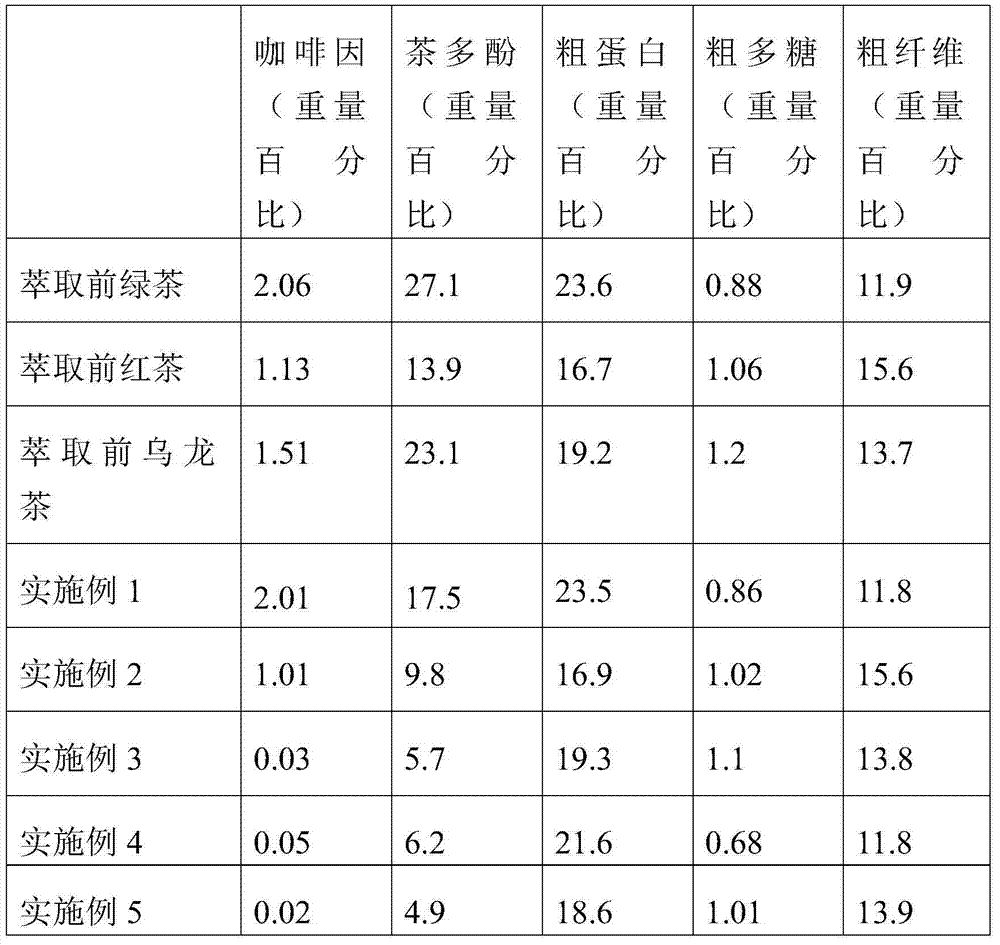

Examples

Embodiment 1

[0028] In the method for subcritical fluid extraction of tea leaf extract of the present embodiment, the tea leaves used are green tea, which specifically includes the following steps:

[0029] 1) Take 600g of tea leaves, at a temperature of 60°C and a pressure of 3MPa, control the solid-liquid ratio of the tea leaves to the dimethyl ether subcritical fluid to be 1:1, and the flow rate of dimethyl ether to be 1kg / h. Ether subcritical fluid continuous dynamic extraction for 30min to obtain the extraction mixture;

[0030] 2) Enrich the extraction mixture obtained in step 1) in a separation tank, and keep the temperature at 60°C and the pressure at 1.2 MPa to vaporize the dimethyl ether subcritical fluid to obtain the tea extract.

[0031] 3) Collect and cool the gaseous dimethyl ether subcritical fluid obtained in step 2), and recycle the liquid dimethyl ether subcritical fluid obtained by condensing.

[0032] 4) When the predetermined extraction time is reached, the extractio...

Embodiment 2

[0034] In the method for subcritical fluid extraction of tea leaf extract of the present embodiment, the tea leaves used are black tea, which specifically includes the following steps:

[0035] 1) Take 60g of tea leaves, at a temperature of 15°C and a pressure of 0.4MPa, control the solid-liquid ratio of the tea leaves to the dimethyl ether subcritical fluid to be 1:20, and the flow rate of dimethyl ether to be 50kg / h. Continuous dynamic extraction of methyl ether with subcritical fluid for 270 minutes to obtain the extraction mixture;

[0036] 2) Enrich the extraction mixture obtained in step 1) in a separation tank, keep the temperature at 40°C, and vacuumize -0.08MPa to vaporize the dimethyl ether subcritical fluid to obtain tea leaf extract .

[0037] 3) Collect and cool the gaseous dimethyl ether subcritical fluid obtained in step 2), and recycle the liquid dimethyl ether subcritical fluid obtained by condensing.

[0038] 4) When the predetermined extraction time is rea...

Embodiment 3

[0040] In the method for subcritical fluid extraction of tea leaf extract in this embodiment, the tea leaf used is oolong tea, which specifically includes the following steps:

[0041]1) Take 600g of tea leaves, use water as an auxiliary agent, and mix the tea leaves with the auxiliary agent at a temperature of 40°C and a pressure of 0.4 MPa. The weight ratio of the auxiliary agent to the tea leaves is 75:100. The solid-liquid ratio of the tea leaves and the dimethyl ether subcritical fluid is controlled to be 1:10, the flow rate of dimethyl ether is 5 kg / h, and the dimethyl ether subcritical fluid is used for continuous dynamic extraction for 150 minutes to obtain an extraction mixture;

[0042] 2) Enrich the extraction mixture obtained in step 1) in a separation tank, and keep the temperature at 50°C and the pressure at 0.2 MPa to vaporize the dimethyl ether subcritical fluid to obtain the tea extract.

[0043] 3) Collect and cool the gaseous dimethyl ether subcritical fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com