A kind of preparation method of textured carbon fiber cloth/carbon nanotube composite material

A technology of carbon nanotubes and textured carbon, which is applied in the direction of carbon fiber, fiber treatment, fiber chemical characteristics, etc., can solve the problems of limiting carbon nanotube loading and its application, high cost of commercial carbon cloth, cumbersome process, etc., to achieve effective Facilitate transmission, broaden application, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

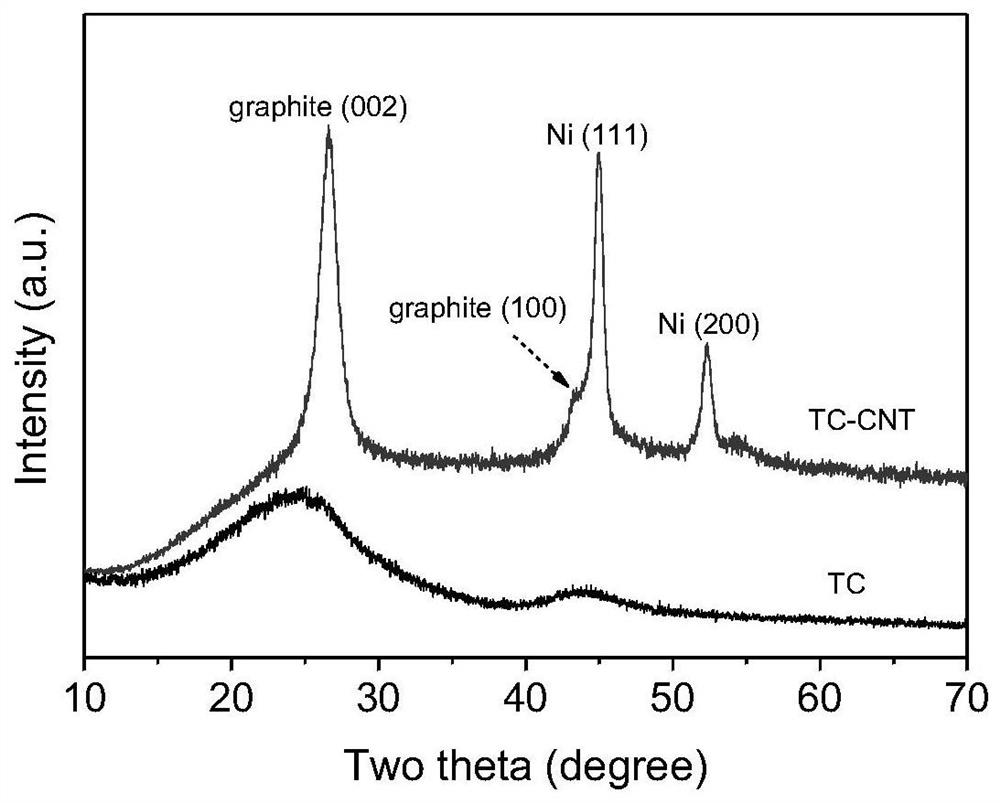

[0030] 1. Ultrasonic cleaning the waste cotton fiber fabrics in acetone, ethanol, and deionized water in sequence to remove dust, impurities and organic pollutants on the fiber surface, and then drying; wash and dry the cotton fiber fabrics in 0.05mol / L six Immerse in the hydrated nickel nitrate aqueous solution for 24 hours, and then dry it at 60°C to a wet state where there is just no flowing water on the surface, and freeze-dry it.

[0031] 2. Put the freeze-dried cotton fiber fabric in a tube furnace, raise the temperature to 800°C at a rate of 8°C / min under the protection of nitrogen gas with a gas velocity of 30sccm, and carbonize at a constant temperature for 60 minutes to obtain a porous material loaded with nickel particles. carbon fiber cloth.

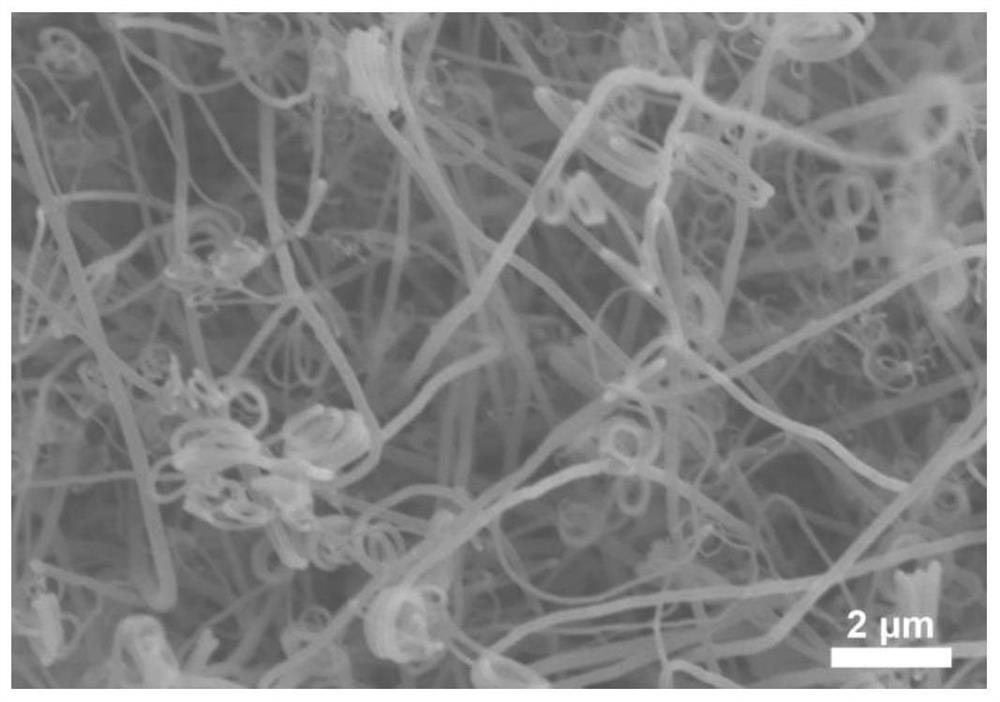

[0032] 3. Adjust the nitrogen gas velocity to 12 sccm, and continue to keep the temperature at 800°C for 15 minutes. During this constant temperature process, connect the flask containing 150 mL of acetonitrile to the inlet o...

Embodiment 2

[0036] 1. Ultrasonic cleaning the waste cotton fiber fabrics in acetone, ethanol, and deionized water in sequence to remove dust, impurities and organic pollutants on the fiber surface, and then dry; wash and dry the cotton fiber fabrics in 0.1mol / L six Immerse in the hydrated nickel nitrate aqueous solution for 24 hours, and then dry it at 60°C to a wet state where there is just no flowing water on the surface, and freeze-dry it.

[0037] 2. Put the freeze-dried cotton fiber fabric in a tube furnace, raise the temperature to 800°C at a rate of 8°C / min under the protection of nitrogen gas with a gas velocity of 30sccm, and carbonize at a constant temperature for 90 minutes to obtain a porous material loaded with nickel particles. carbon fiber cloth.

[0038] 3. Adjust the nitrogen gas velocity to 15 sccm, and continue to keep the temperature at 800°C for 15 minutes. During this constant temperature process, connect the flask containing 150 mL of acetonitrile to the inlet of th...

Embodiment 3

[0040] 1. Ultrasonic cleaning the waste cotton fiber fabric in acetone, ethanol, and deionized water in sequence to remove dust, impurities and organic pollutants on the fiber surface, and then dry; wash and dry the cotton fiber fabric in 0.02mol / L six Immerse in the hydrated nickel nitrate aqueous solution for 24 hours, and then dry it at 60°C to a wet state where there is just no flowing water on the surface, and freeze-dry it.

[0041] 2. Put the freeze-dried cotton fiber fabric in a tube furnace, raise the temperature to 800°C at a rate of 8°C / min under the protection of nitrogen gas with a gas velocity of 30sccm, and carbonize at a constant temperature for 60 minutes to obtain a porous material loaded with nickel particles. carbon fiber cloth.

[0042] 3. Adjust the nitrogen gas rate to 12 sccm, and continue to keep the temperature at 800°C for 10 minutes. During this constant temperature process, connect the flask containing 150mL of acetonitrile to the inlet of the tube f...

PUM

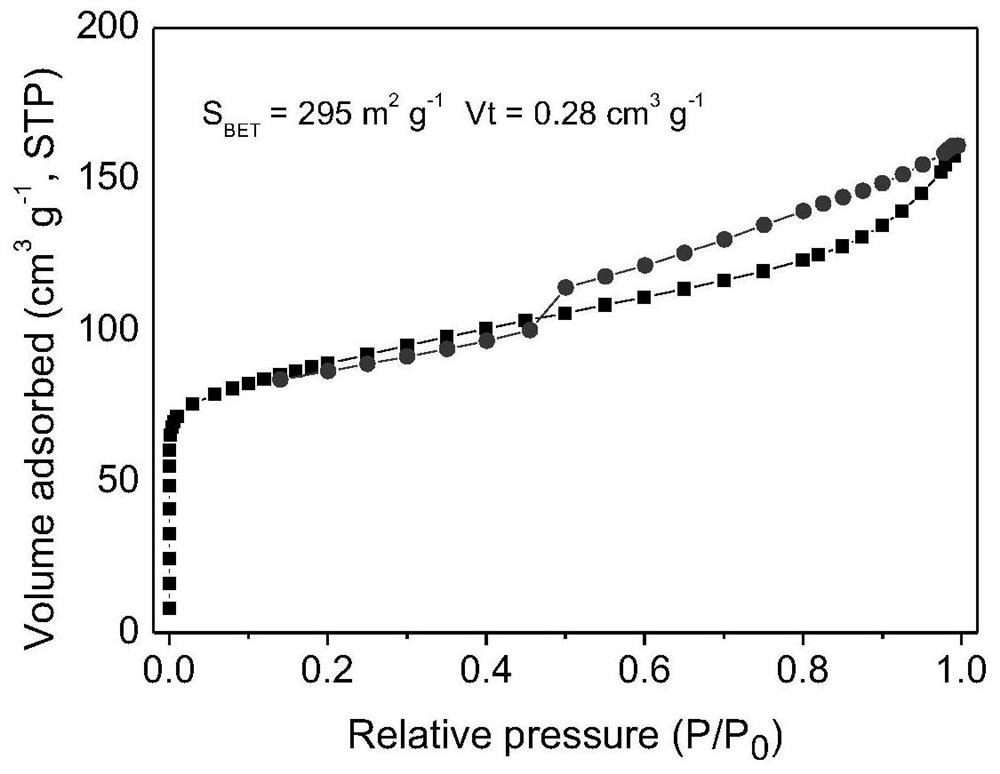

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com