Temperature sensor and thermal flow rate measurement device

A technology of temperature sensor and measuring device, which is applied in the direction of measuring device, measuring device shell, liquid/fluid solid measurement, etc., and can solve problems such as fluids that cannot transfer heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

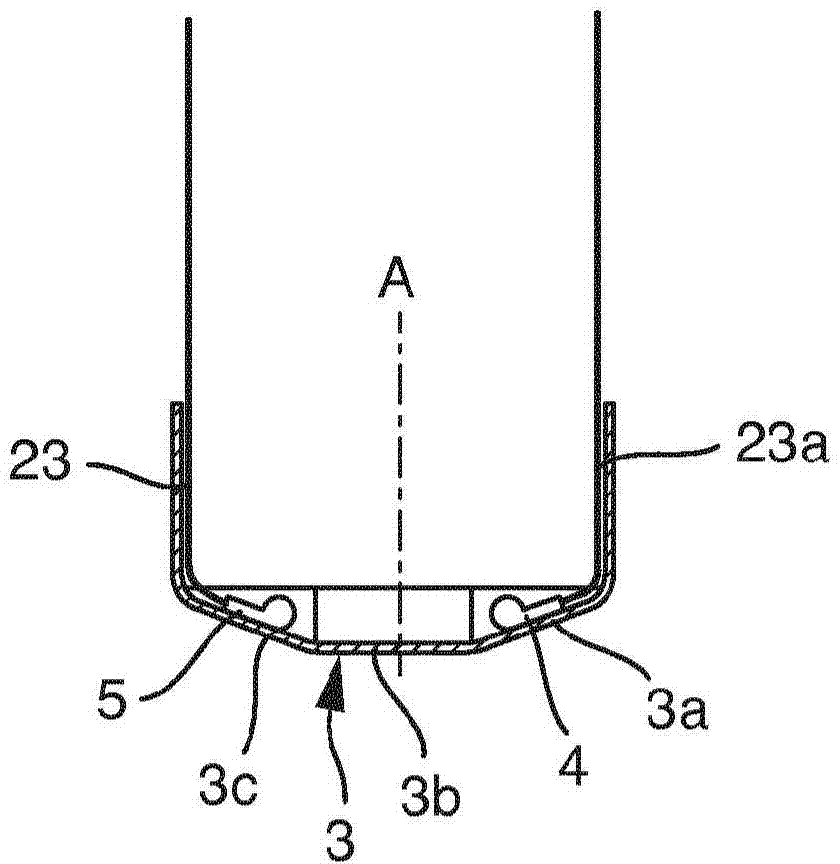

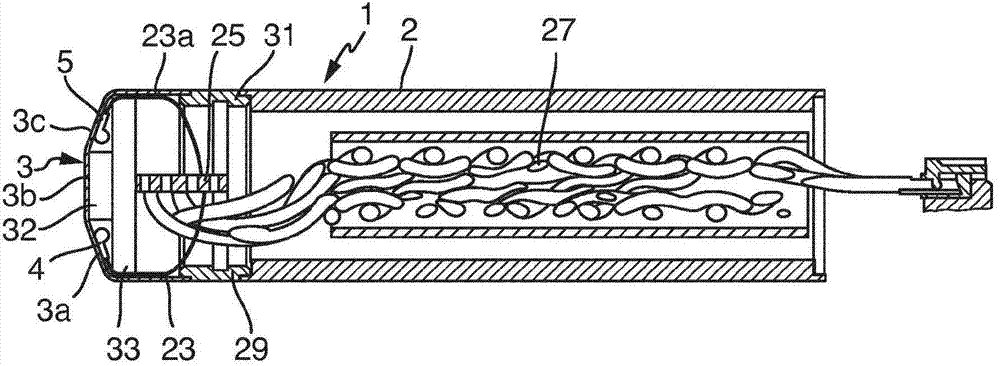

[0030] figure 1 A sensor of a thermal flow measuring device is shown, wherein the sensor is embodied as a thermal mass flow sensor 1 .

[0031] Traditionally, thermal flow measuring devices usually use two heatable resistance thermometers, which are implemented as identical as possible and are most often arranged in a pin-shaped metal sleeve, in a so-called stylus, or In a cylindrical metal sleeve, in thermal contact with the medium flowing through the measuring tube or through the pipe. For industrial applications, usually two resistance thermometers are installed in the measuring tube; however, resistance thermometers can also be installed directly in the pipe. One of the two resistance thermometers is a so-called active sensor element, which is heated by a heating unit. The heating unit provided is either an additional resistance heater or, in the case of a resistance thermometer as a resistance element, such as an RTD (Resistive Temperature Device) sensor, which is conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com