A low-frequency permanent magnet vibration generator

A vibrating generator and permanent magnet technology, applied to electrical components, electromechanical devices, etc., to achieve the effects of reducing magnetic flux leakage, facilitating assembly, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

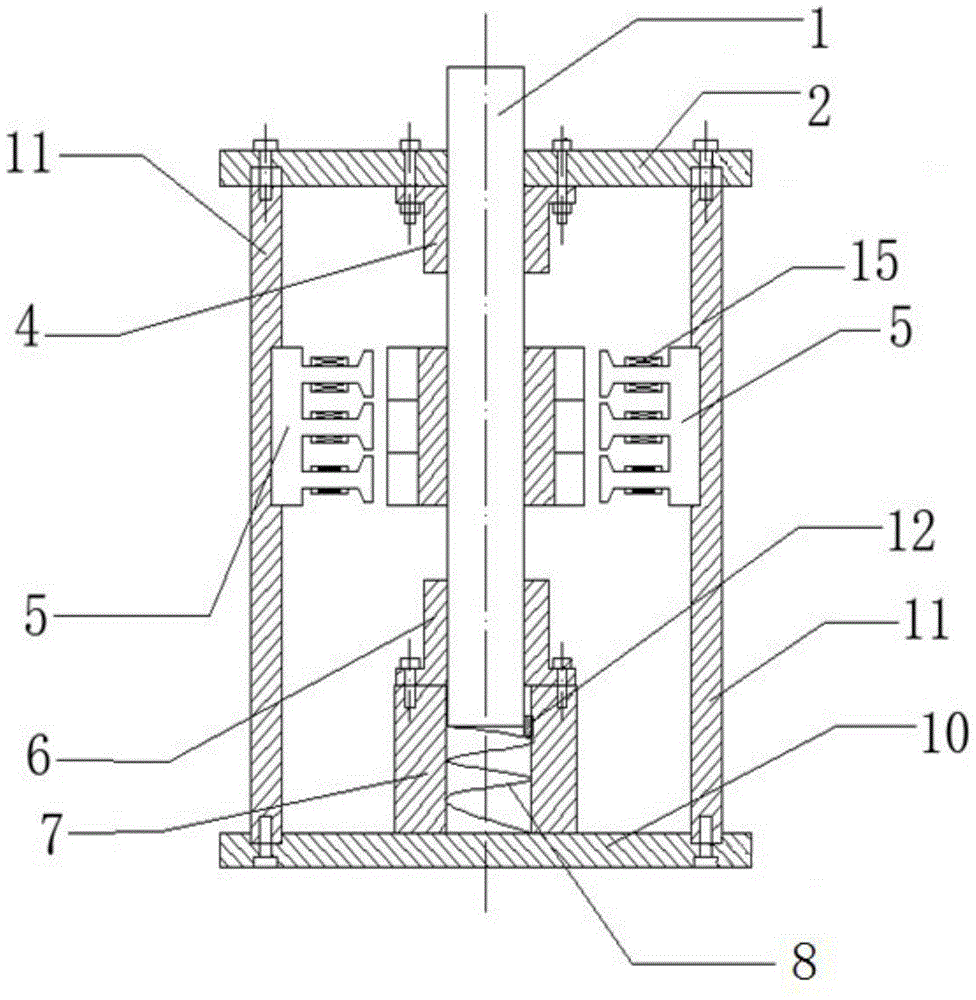

[0040] This embodiment adopts the above-mentioned connection method, the upper end cover and the lower end cover are cuboid plates with square grooves on the edges, and the grooves of the upper and lower end covers are used for embedding four side plates. Vibration shaft part: Use cylindrical austenitic stainless steel (non-magnetic material) as the vibration shaft 1 to avoid affecting the magnetic circuit. The total length of the vibrating shaft is 890mm, the diameter at both ends is 25mm, the installation length of the middle part of the silicon steel sheet of the moving element is 150mm, and the ring diameter is 10mm, and there are four 5mm deep moving silicon steel sheet grooves with an arc of 60° evenly around it. 26. The length of the vibration axis at the upper end of the mover silicon steel sheet 21 is 370 mm, and the length of the vibration axis at the lower end of the mover silicon steel sheet is 370 mm. Each mover silicon steel sheet groove 26 respectively places th...

Embodiment 2

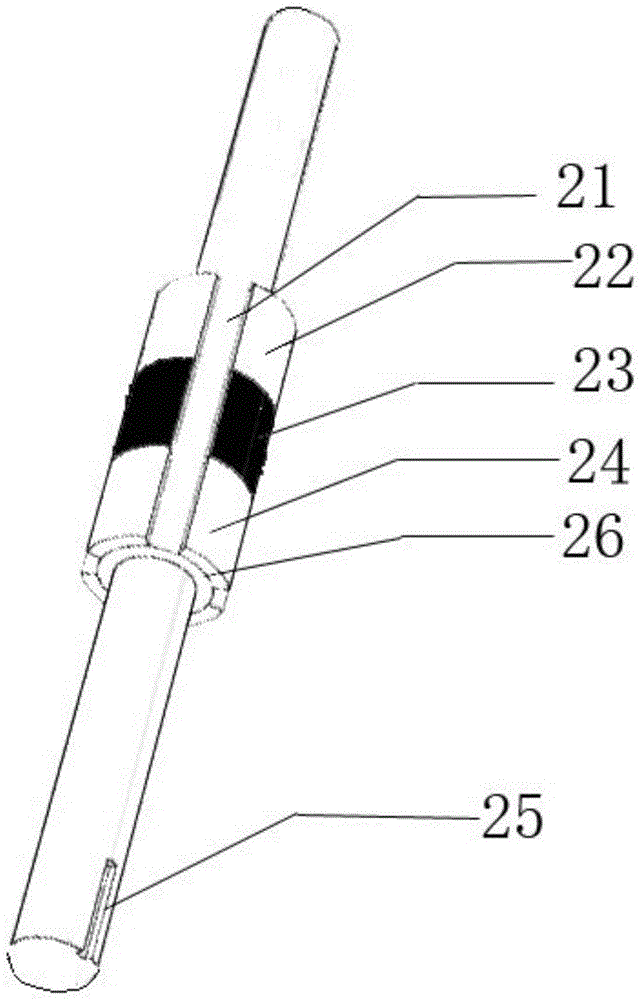

[0043] In the present embodiment, the vibration axis 1 is a 25mm cylindrical stainless steel, and the concave part of the silicon steel sheet in the middle is equipped with arc-shaped magnetic tile NdFeB permanent magnets 22-24 (Nd2Fe14B, model N45), and the three permanent magnets are vertically attached together. Polarity is reversed successively, a week altogether four groups, end has 3.5 * 4 * 8mm square keyway 25.

[0044] Considering the strong attraction between the permanent magnet and the yoke, the circular flange linear bearings (upper flange bearing 4 and lower flange bearing 6) distributed at both ends are used to limit the vibration axis, and the permanent magnet and the yoke The gravitational force between the yokes is converted into the rolling friction force between the vibrating shaft and the bearing, which greatly reduces the influence of the magnetic force on the vibration of the generator.

[0045] Figure 5 It is the waveform diagram of the output electro...

Embodiment 3

[0047] In this embodiment, the above-mentioned connection method is adopted, and the upper end cover and the lower end cover are tightly and fixedly connected with the four side plates through mutually matching mortise joint structures. The generator can output relatively large output voltage when the vibration frequency is 1-5Hz and the vibration displacement peak value is 100-200mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com