A Machine Vision Positioning Method for Surface Mount Components

A surface mount component and machine vision technology, applied in the electrical field, can solve problems such as errors and lack of precision, and achieve the effects of high precision, wide application, and avoidance of dependencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

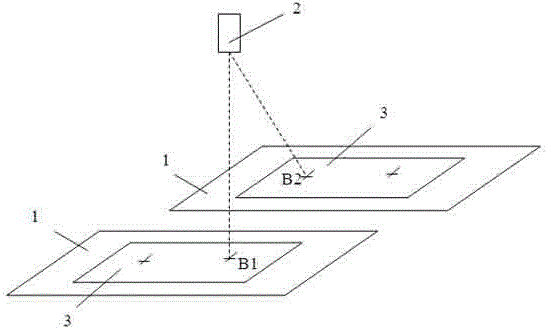

Embodiment 1

[0020] A machine vision positioning method for surface mount components of the present invention includes a process of using a camera to collect and analyze images of surface mount components, wherein, in the process of using a camera to collect and analyze images of surface mount components , a pallet platform 1 that can translate and rotate in the horizontal direction is set, a camera 2 is fixedly arranged above the pallet platform 1, and an image is set between the camera 2 and a computer (not shown in the figure) In the data transmission channel, a calibration step is first performed, and then a positioning step of the workpiece 3 to be processed is performed. In the calibration step, a circular feature point is made on the pallet platform 1 and placed at the center of the field of view of the camera 2 , and then translate the pallet platform 1 in the X direction and the Y direction respectively, use the camera 2 to collect images of circular feature points in more than two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com