Double-wedge sealed buckled type reverse stop bearing

A stop bearing and snap-fit technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of high straightness, verticality and coaxiality, reducing wedge and bearing capacity, and reverse stop failure. , to ensure continuous lubricity, improve wedging ability, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

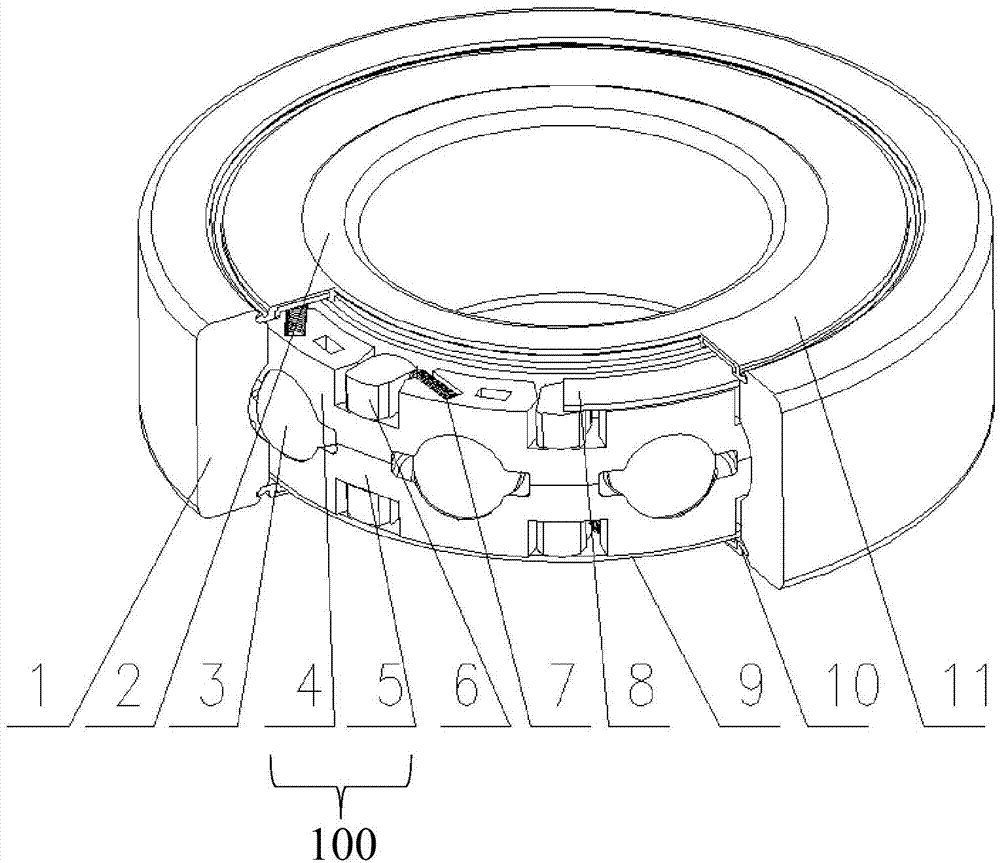

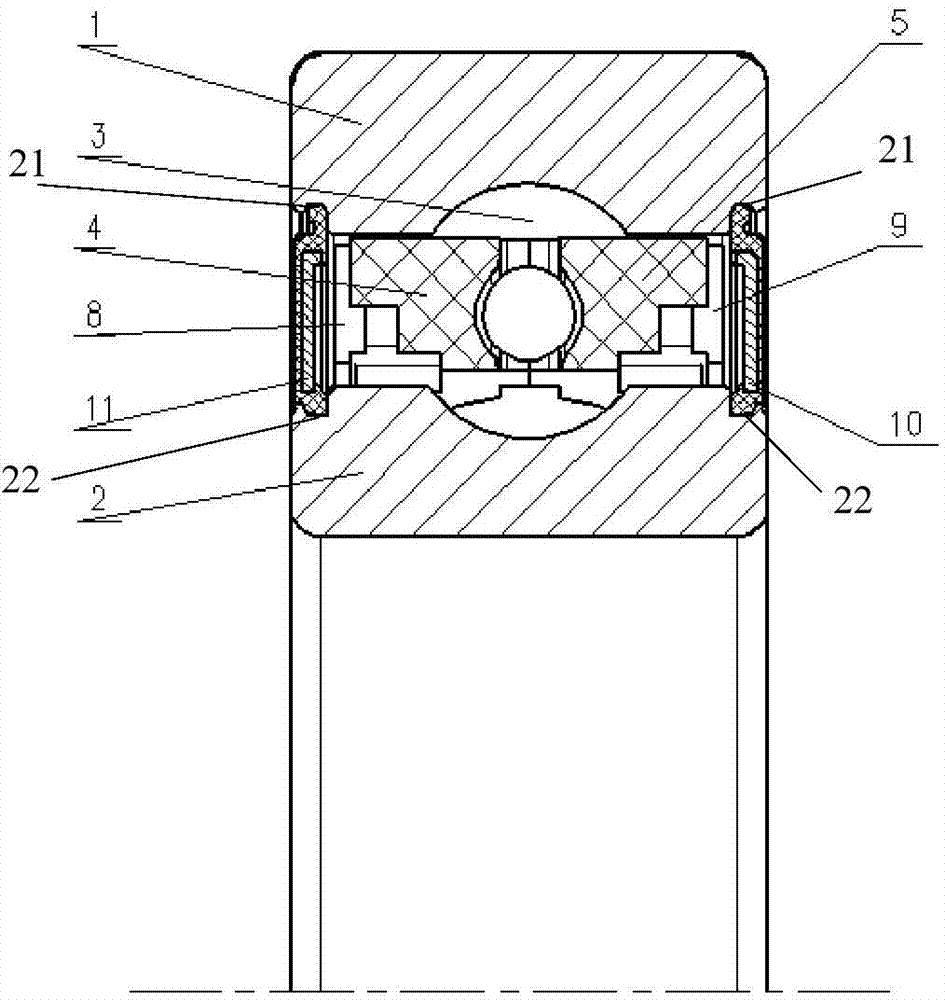

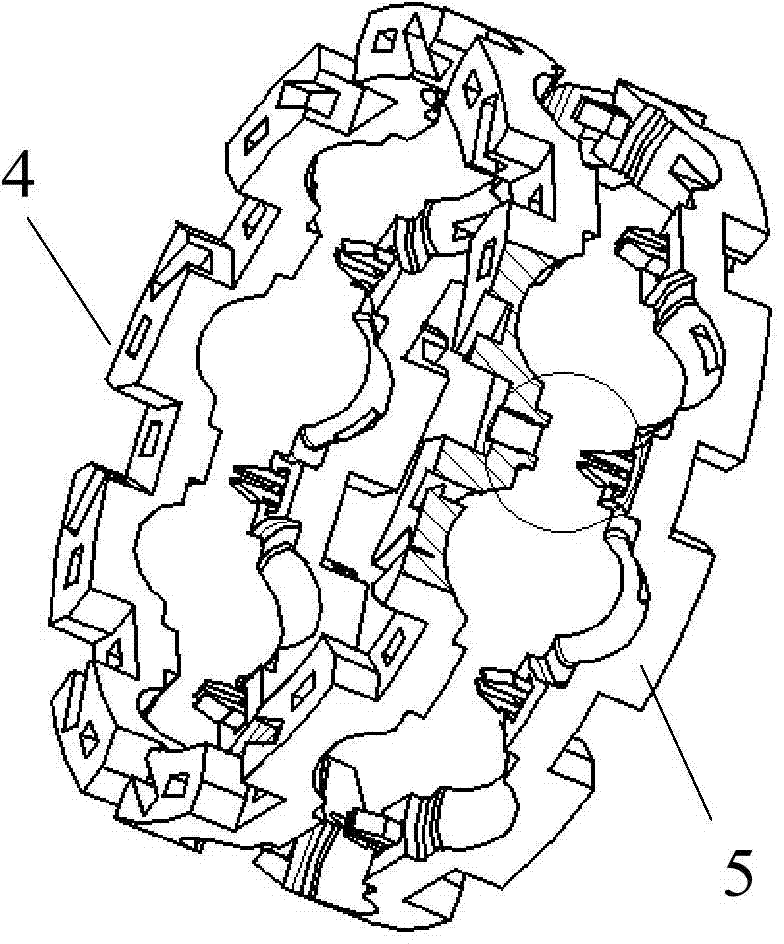

[0023] Such as figure 1 and figure 2 As shown, the double-wedge seal buckle reverse stop bearing proposed by the present invention includes an outer ring 1, an inner ring 2, steel balls 3, an upper retainer 4, a lower retainer 5, wedges 6, springs 7, and an upper fixed cover 8, the lower fixed cover 9, the upper sealing ring 11 and the lower sealing ring 10.

[0024] The upper holder 4 and the lower holder 5 are snapped together to form a holder 100, wherein both the upper holder 4 and the lower holder 5 are made of nylon. The upper cage 4 and the lower cage 5 are interlocked with the steel ball 3 , the outer ring 1 and the inner ring 2 as a whole, and the cage 100 is located between the outer ring 1 and the inner ring 2 . The steel ball 3 is located in the cage 100 and can roll so that the outer ring 1 and the inner ring 2 can rotate relative to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com