Oriented electrical steel sheets and method for manufacturing the same

A technology of grain-oriented electrical steel sheet and manufacturing method, applied in the field of grain-oriented electrical steel sheet and its manufacturing, can solve the problems of complicated manufacturing process and rising cost, and achieve the effects of reducing manufacturing cost, reducing manufacturing cost and excellent iron loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

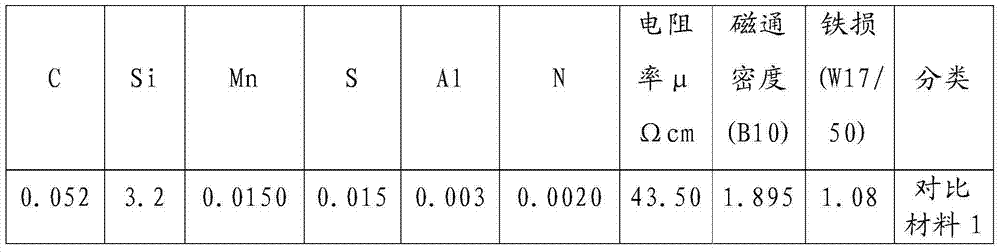

Examples

Embodiment 2

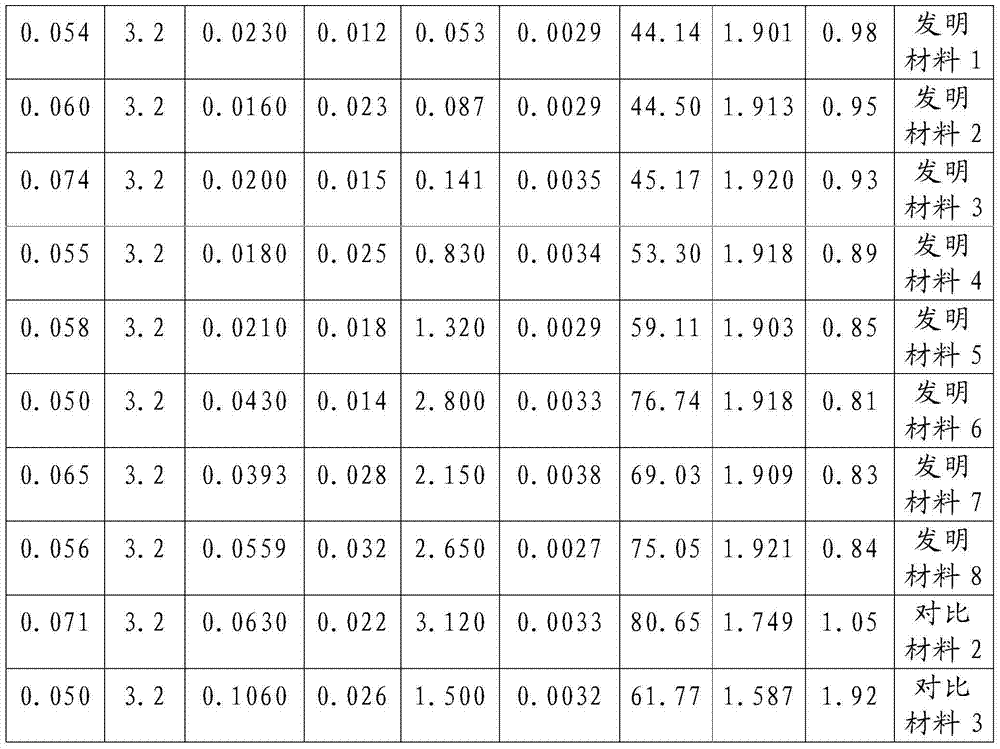

[0081] The slabs containing 0.05% C, 3.2% Si, 0.03% Mn, 0.003% Al, 0.003% N as basic components, and adding different contents of S, Sn, Sb, and Bi were vacuum melted into ingots.

[0082] Next, the ingot was heated at a temperature of 1250° C., and then hot-rolled to a thickness of 2.3 mm. After the hot-rolled hot-rolled sheet was heated to a temperature of 950° C., soaking was performed for 180 seconds, and then the hot-rolled sheet was annealed.

[0083] After pickling the steel plate annealed by the hot-rolled plate, it is cold-rolled into a cold-rolled plate with a thickness of 0.30 mm. The cold-rolled steel sheet was held at a temperature of 810° C. for 180 seconds in a moist hydrogen-nitrogen mixed gas atmosphere to perform decarburization and recrystallization heat treatment.

[0084] After coating the annealing separator MgO on the steel sheet, final annealing was performed in a coiled state. The final annealing was carried out in a mixed atmosphere of 25% by volum...

Embodiment 3

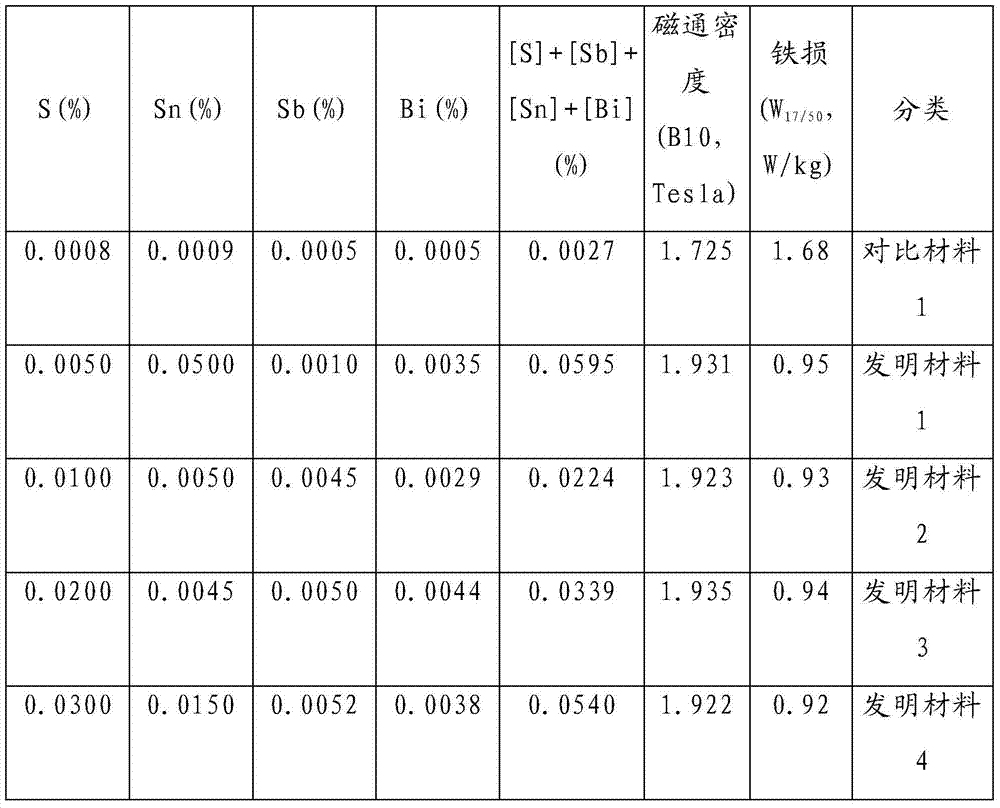

[0092] The slab contains 0.045% of C, 3.15% of Si, 0.020% of Mn, 0.020% of S, 0.05% of Sn, 0.03% of Sb, 0.015% of Bi in % by weight as a basic component, and the following table Al and N contents were varied as shown in 3, and the slab was vacuum melted into ingots.

[0093] Next, after heating the ingot at a temperature of 1200° C., it was hot-rolled to a thickness of 2.3 mm. Heat the hot-rolled sheet after hot rolling to 1100° C., then heat soak at a temperature of 900° C. for 120 seconds, and then anneal the hot-rolled sheet.

[0094] Thereafter, the steel sheet annealed by the hot-rolled sheet was cooled, pickled, and cold-rolled into a cold-rolled sheet having a thickness of 0.23 mm. The cold-rolled steel sheet is kept at 850° C. for 180 seconds in a moist hydrogen-nitrogen mixed gas atmosphere to perform decarburization and recrystallization heat treatment.

[0095] After coating the annealing separator MgO on the steel sheet produced in this way, final annealing was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com