Railway vehicle static weighing detection method, automatic walking trolley and automatic detection and weighing system

A technology for automatic walking and railway vehicles, which is applied in the direction of railway vehicle shape measuring devices, railway car body parts, railway auxiliary equipment, etc., and can solve problems such as error-prone, difficult weighing operations, and large errors in the weighing weight of a single wheel, and achieve Easy to operate, wide application range, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

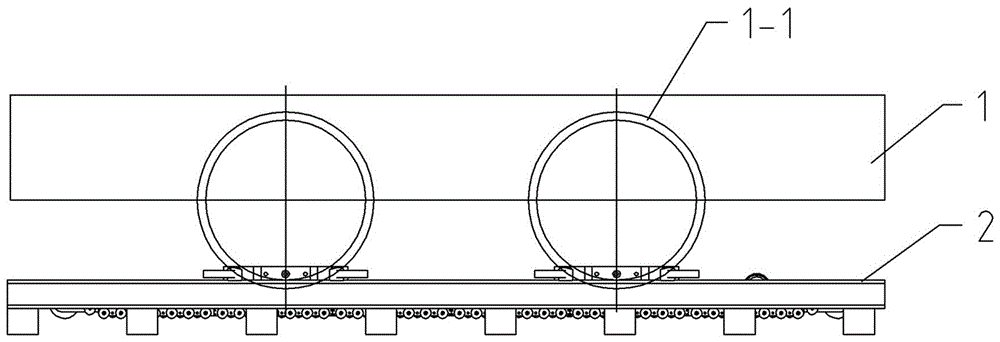

[0036] see figure 1 , figure 2 , the present embodiment discloses a static weighing detection method for a railway vehicle, and its implementation is as follows:

[0037] 1) Use one or two self-propelled trolleys to run on the sleeper in the middle of the railway track under the vehicle;

[0038] 2) The self-propelled trolley is equipped with a lifting component and a load cell component; the vehicle is lifted by the lifting component, and two or four of the front bogie and the rear bogie are simultaneously lifted by one self-propelling trolley. two or four wheels of the bogie and weigh them; or if figure 1 As shown, one automatic walking trolley is used to lift two or four wheels of the front and rear bogies in turn and weigh them, or two front and rear automatic walking trolleys are used, and the front and rear two automatic walking trolleys Lift the two or four wheels of the front and rear bogies respectively and weigh them to obtain the vehicle quality signal;

[0039...

Embodiment 2

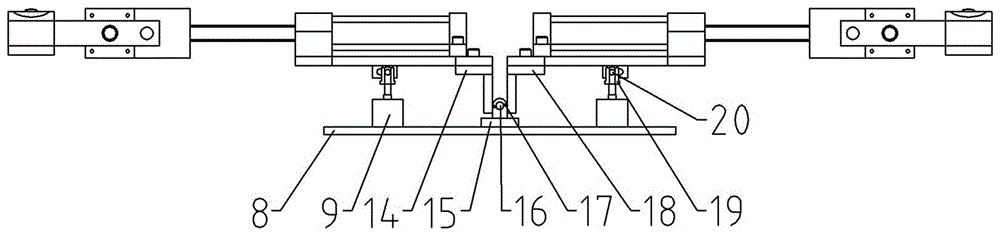

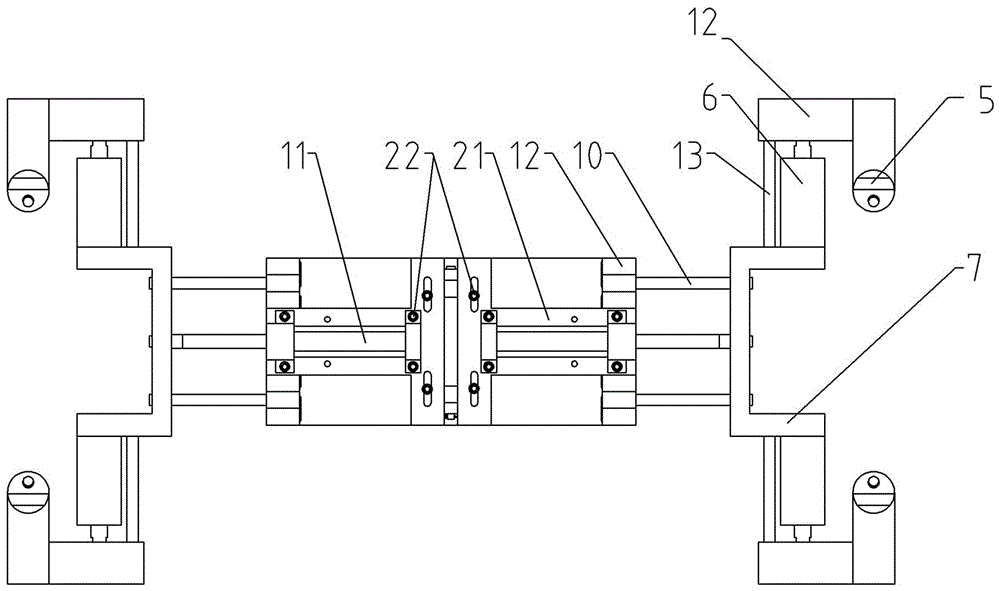

[0043] see figure 2 , image 3 , Figure 4 , the present embodiment discloses a self-propelled trolley for realizing the aforementioned railway vehicle static weighing detection method, such as figure 2 As shown: the self-propelled trolley includes a frame and a traveling mechanism, an electrical control system, and a hydraulic control system. Such as image 3 , Figure 4 As shown: there are two sets of lifting assemblies at the front and rear on the vehicle frame, and each set of lifting assemblies 4-2 includes two sets of left and right lifting mechanisms. 11 is fixed on the vehicle frame, and each group of lifting mechanisms is provided with at least one lifting cylinder 5, and each group of lifting mechanisms corresponds to a wheel of the train bogie; the hydraulic control system cooperates with the lifting components.

Embodiment 3

[0045] The difference between the self-propelled trolley disclosed in this embodiment and used to implement the above-mentioned static weighing detection method for railway vehicles is that a group of lifting components are provided on the frame, and the left and right two parts are used for weight measurement. The group lifting mechanism lifts a wheel on both sides of the front or rear of the train bogie respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com