Clutch of automobile generator spindle

A technology for automotive generators and clutches, which is applied in the direction of non-mechanical drive clutches, clutches, magnetic drive clutches, etc. It can solve problems such as unfavorable maintenance, inability to combine and slip, and uneven clutch combination, so as to achieve fast and reliable response and good heat dissipation effect, the effect of low working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

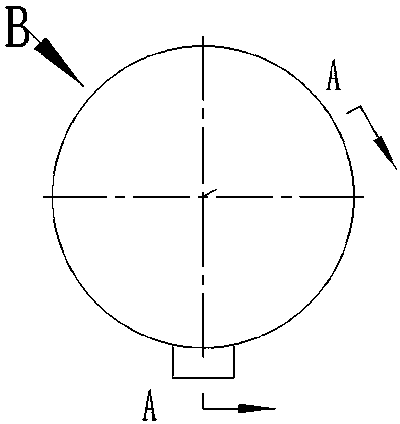

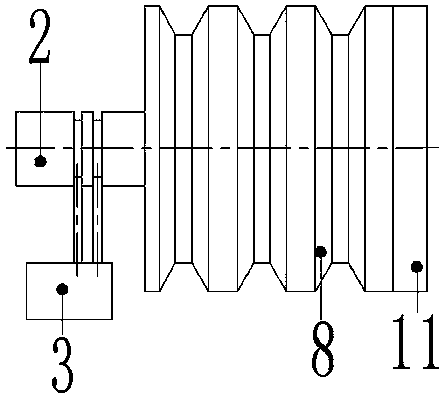

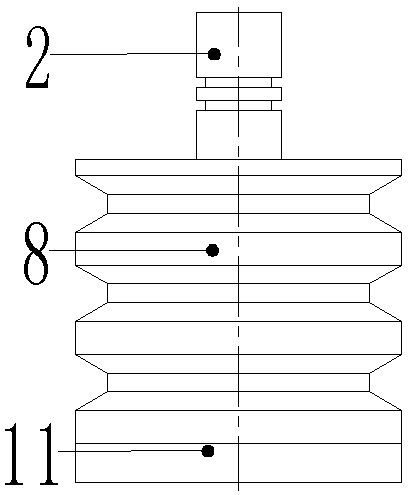

[0060] Embodiment 1: as Figure 1-27 As shown, an automobile generator main shaft clutch includes a spline shaft 2, a controller 3, a large bearing 4, an electromagnet coil 5, a slider 6, a three-pivot assembly 7, a belt pulley 8, a spring 9, and a small bearing 10. End cover 11; the spline shaft 2 is connected to the belt pulley 8 through the large bearing 4, one end of the spline shaft 2 is connected to the external generator main shaft 1, and the other end of the spline shaft 2 is connected to the end cover 11 through the small bearing 10 Connected, the end cover 11 is fixed on the belt pulley 8 by bolts, the belt pulley 8 is externally connected to the engine engine 12, the controller 3 is connected to the spline shaft 2 through a brush, and the controller 3 is connected with the electromagnet coil 5 to realize the electromagnet coil 5. The switch of the power supply. Electromagnet coil 5, slide block 6, three pivot assembly 7, spring 9 are successively installed on belt p...

Embodiment 2

[0061] Embodiment 2: as Figure 1-27 As shown, an automobile generator main shaft clutch includes a spline shaft 2, a controller 3, a large bearing 4, an electromagnet coil 5, a slider 6, a three-pivot assembly 7, a belt pulley 8, a spring 9, and a small bearing 10. End cover 11; the spline shaft 2 is connected to the belt pulley 8 through the large bearing 4, one end of the spline shaft 2 is connected to the external generator main shaft 1, and the other end of the spline shaft 2 is connected to the end cover 11 through the small bearing 10 Connected, the end cover 11 is fixed on the belt pulley 8 by bolts, the belt pulley 8 is externally connected to the engine engine 12, the controller 3 is connected to the spline shaft 2 through a brush, and the controller 3 is connected with the electromagnet coil 5 to realize the electromagnet coil 5. The switch of the power supply. Electromagnet coil 5, slide block 6, three pivot assembly 7, spring 9 are successively installed on belt p...

Embodiment 3

[0063] Embodiment 3: as Figure 1-27 As shown, an automobile generator main shaft clutch includes a spline shaft 2, a controller 3, a large bearing 4, an electromagnet coil 5, a slider 6, a three-pivot assembly 7, a belt pulley 8, a spring 9, and a small bearing 10. End cover 11; the spline shaft 2 is connected to the belt pulley 8 through the large bearing 4, one end of the spline shaft 2 is connected to the external generator main shaft 1, and the other end of the spline shaft 2 is connected to the end cover 11 through the small bearing 10 Connected, the end cover 11 is fixed on the belt pulley 8 by bolts, the belt pulley 8 is externally connected to the engine engine 12, the controller 3 is connected to the spline shaft 2 through a brush, and the controller 3 is connected with the electromagnet coil 5 to realize the electromagnet coil 5. The switch of the power supply. Electromagnet coil 5, slide block 6, three pivot assembly 7, spring 9 are successively installed on belt p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com