Printing method for pattern having 3D visual effect on mobile phone lens

A printing method and visual effect technology, which is applied in the field of printing technology with 3D visual effect patterns, and can solve problems such as numerous processes, low yield, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

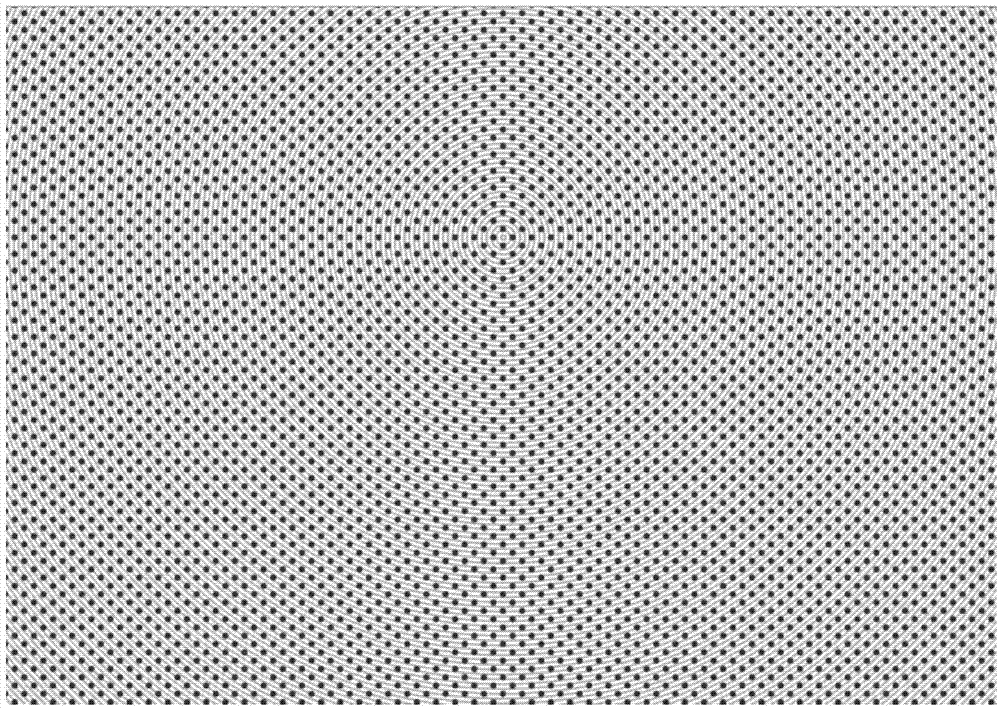

[0019] Step 1. The first silk screen dots: Use a silk screen to screen a layer of black dots on one side of the glass. The diameter is 0.2mm and the spacing is 0.6mm. Materials needed: black oil: varnish: curing agent: Thinner=100:50:10:3, screen mesh is 500 mesh composite steel wire mesh, squeegee hardness is 75A, baking temperature is 150℃, baking time is 3min, ink thickness is 2μm.

[0020] Step 2. The second silk-screen CD pattern: A layer of varnish is silk-printed on the entire surface of the first small dot, the wire diameter is 0.1mm, and the spacing is 0.2mm. Materials needed: Shenhua varnish (one-component ink), 550 mesh composite steel wire mesh, squeegee hardness 75A, baking temperature 150°C, baking time 4min, ink thickness 2μm.

[0021] Step 3. Screen printing white oil 1: Screen printing a layer of white oil on the entire surface of the second CD pattern: Material required: ink: curing agent: thinner = 140:1:0, screen mesh number is 350 meshes Ester net yarn, squeeg...

Embodiment 2

[0027] Step 1. The first silk-screen dots: a layer of semi-transparent black dots with a diameter of 0.4mm and a spacing of 0.8mm with a silk screen on one side of the glass. The required materials: black oil: varnish: curing Agent: thinner=100:60:15:6, screen mesh is 450 mesh composite steel wire mesh, squeegee hardness is 80A, baking temperature is 150℃, baking time is 3min, ink thickness is 2μm.

[0028] Step 2. The second silk-screen CD pattern: A layer of varnish is silk-printed on the entire surface of the first small dot, the wire diameter is 0.15mm, and the spacing is 0.4mm. Materials needed: Shenhua varnish (one-component ink), 500 mesh composite steel wire mesh, squeegee hardness 80A, baking temperature 150°C, baking time 4min, ink thickness 2μm.

[0029] Step 3. Screen printing white oil 1: Screen printing a layer of white oil on the entire surface of the second CD pattern: Material required: ink: curing agent: thinner = 140:2:1, screen mesh number is 350 meshes Ester m...

Embodiment 3

[0034] Step 1. The first silk-screen dots: a layer of semi-transparent black dots with a diameter of 0.6mm and a spacing of 0.9mm with a silk screen on one side of the glass. The required materials: black oil: varnish: curing Agent: thinner=100:60:15:6, screen mesh number is 400 mesh composite steel wire mesh, squeegee hardness 80A, baking temperature is 150°C, baking time 3min, ink thickness 2μm.

[0035] Step 2. The second silk-screen CD pattern: silk-print a layer of varnish on the entire surface of the first small dot, the wire diameter is 0.1mm, and the spacing is 0.1mm. Materials needed: Shenhua varnish (one-component ink), 650 mesh composite steel wire mesh, squeegee hardness 80A, baking temperature 150°C, baking time 4min, ink thickness 2μm.

[0036] Steps 3 to 5 are the same as in Example 2.

[0037] After the above steps, a mobile phone lens with a 3D visual effect pattern with an overall ink thickness of 15-20 μm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com