Pharmaceutical composition containing colistin sulfate and preparation method of pharmaceutical composition

A technology of colistin sulfate and composition, which is applied in the field of pharmaceutical composition containing colistin sulfate and its preparation, and can solve the problems of ineffective treatment and growth promotion, difficulty in achieving content uniformity, and colistin bioavailability. In order to improve the effective drug concentration and action time, improve the intestinal morphology, and reduce the frequency of medication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

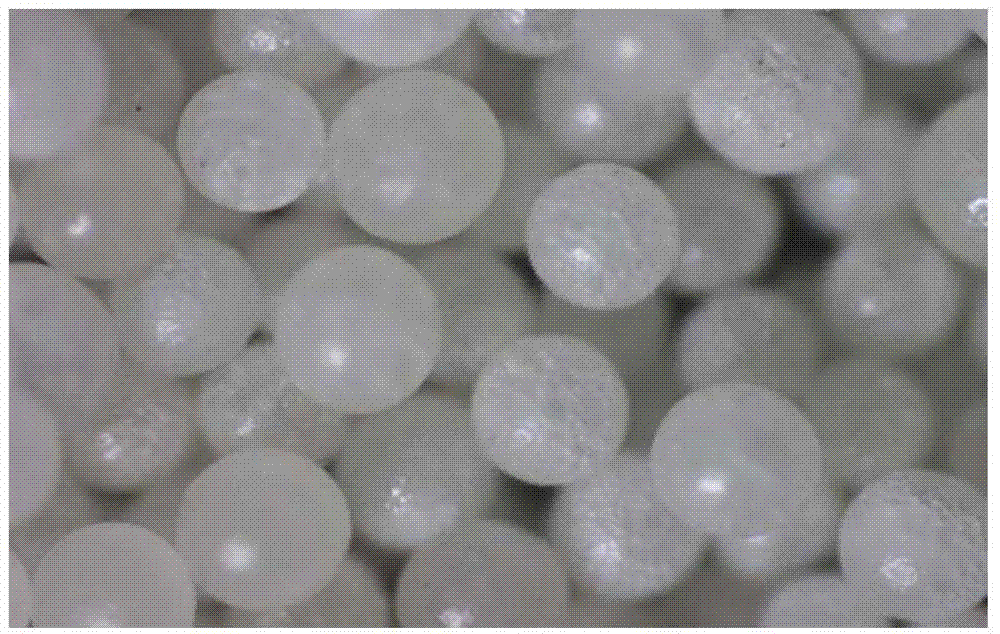

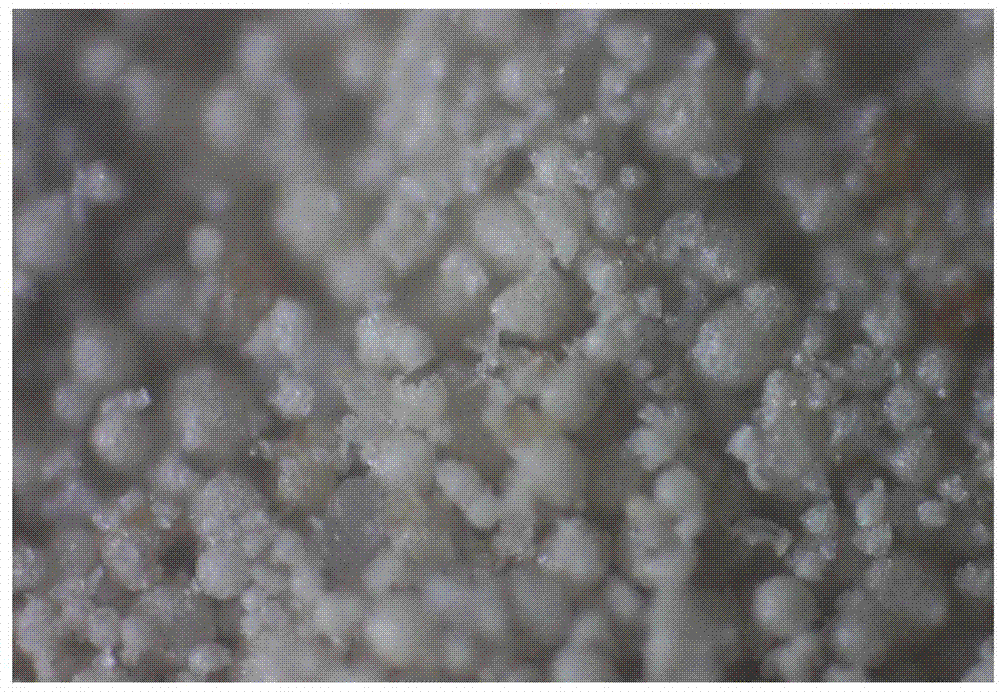

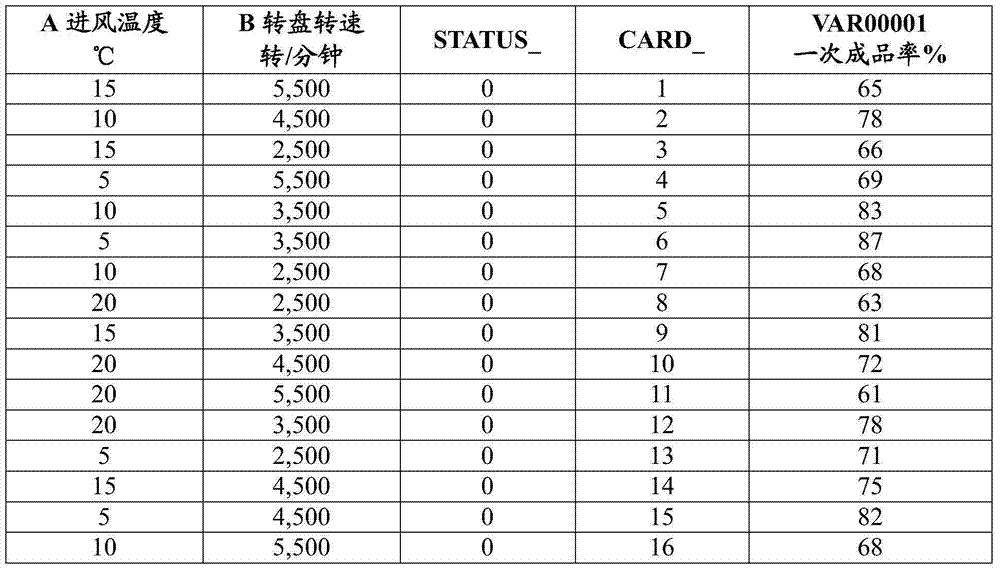

[0048] Select 172.5kg of stearic acid as an embedding agent, put it into a 300L heating tank (effective volume: 200kg), heat it to 100°C-130°C while stirring continuously to completely melt the stearic acid, and then cool it to 90°C-100°C , the accurately weighed 27.5kg colistin sulfate crude drug is dropped into the heating tank, and stirred for 30 minutes with a stirring speed of 100 rev / min, so that the two are fully mixed. Start the centrifugal turntable sprayer, set the rotational speed of the centrifugal turntable to 3500 rpm, the inlet air temperature to ≤15°C, and the outlet air temperature to 25°C. The prepared granules were sieved with a 24-60 mesh vibrating sieve to finally obtain 191.4 kg of 10% colistin sulfate microcapsule granules with a yield of 95.7%.

Embodiment 2

[0050] Select 172.5kg of glyceryl monostearate as an embedding agent, put it into a 300L heating tank (with an effective volume of 200kg), heat it to 100°C-130°C, and stir continuously to completely melt the glyceryl monostearate, and then cool it To 90 ℃ ~ 100 ℃, accurately weighed 27.5kg of colistin sulfate crude drug into the heating tank, stirring with a stirring speed of 100 rpm for 30 minutes, so that the two are fully mixed evenly. Start the centrifugal turntable sprayer, set the rotational speed of the centrifugal turntable to 3500 rpm, the inlet air temperature to ≤15°C, and the outlet air temperature to 25°C. The prepared granules were sieved with a 24-60 mesh vibrating sieve to finally obtain 188.4 kg of 10% colistin sulfate microcapsule granules with a yield of 94.2%.

Embodiment 3

[0052] Select 162.5kg of embedding agent stearic acid and 10kg of paraffin, put them into a 300L heating tank (effective volume is 200kg), heat to 100°C-130°C, and keep stirring at the same time to completely melt the stearic acid and paraffin, and then cool to At 90°C to 100°C, put 27.5kg of accurately weighed colistin sulfate bulk drug into a heating tank, and stir for 30 minutes at a stirring speed of 100 rpm to fully mix the two. Start the centrifugal turntable sprayer, set the rotational speed of the centrifugal turntable to 3500 rpm, the inlet air temperature to ≤15°C, and the outlet air temperature to 25°C. The prepared granules were sieved with a 24-60 mesh vibrating sieve to finally obtain 193.8 kg of 10% colistin sulfate microcapsule granules with a yield of 96.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com