Telescoping lunch box production method

A production method and lunch box technology, applied in travel goods, applications, clothing, etc., can solve the problems of troublesome handling, pollution, waste of resources, etc., and achieve the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The telescopic lunch box production method of the present invention, its concrete steps are as follows:

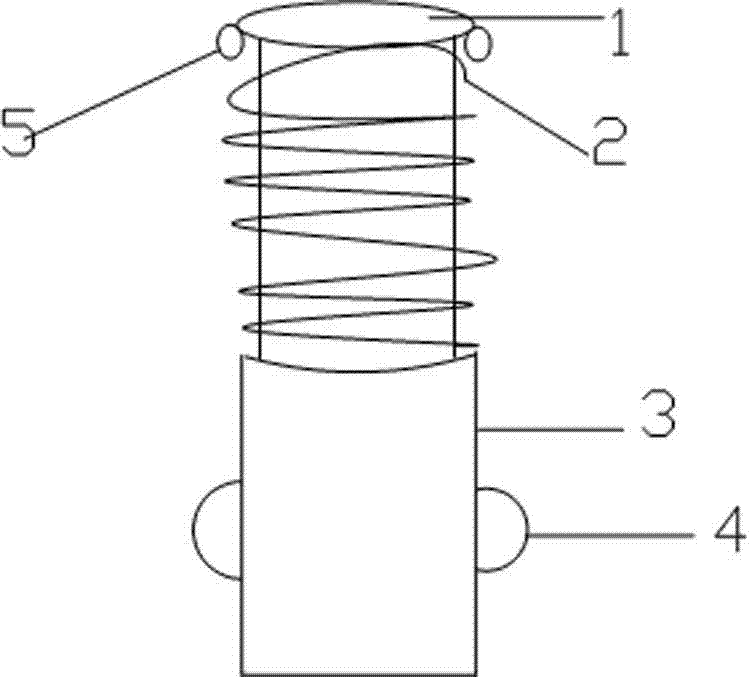

[0014] ①. The retractable lunch box includes: a box cover 1, the box body 2 is connected to the bottom of the box cover 1, the box body 2 is screwed to the box bottom 3, handles 4 are arranged on both sides of the outer wall of the box bottom 3, and the box cover 1 is provided with With clasp 5;

[0015] ②, Integral molding box cover 1 and box body 2;

[0016] ③. Weld the clasp 5 on the box cover 1;

[0017] ④. Make external threads by tapping on the outer wall of box body 2, and make internal threads by tapping on the inner wall of box bottom 3, and the meshing teeth of the outer wall threads of box body 2 and the inner wall threads of box bottom 3 are consistent;

[0018] ⑤. Fix the handle 4 on the outer wall of the box bottom 3;

[0019] ⑥. Screw the box body 2 into the bottom 3 of the box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com