Potato-containing mutton soup and processing method thereof

A processing method and potato technology, applied in application, food preparation, food science, etc., can solve the problems of low nutritional value and poor taste, and achieve the effect of delicious taste, consistent quality and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

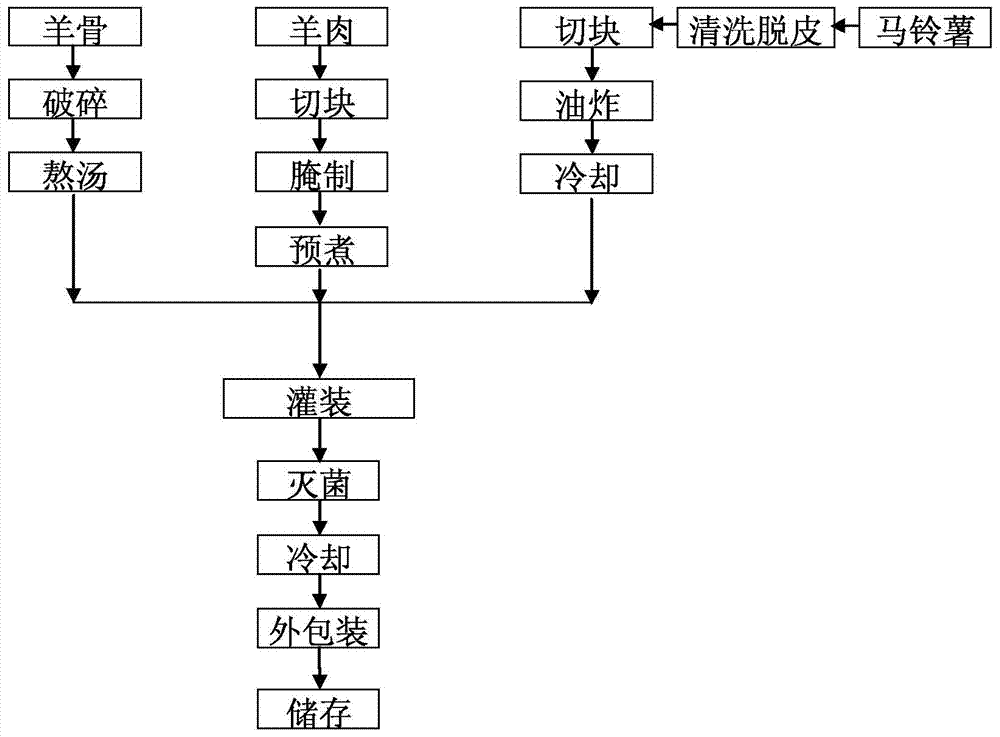

Image

Examples

Embodiment 1

[0025] The invention provides a potato and mutton stew, which comprises the following components in parts by mass: 1 part of mutton meat base, 1 part of fried potato pieces and 1 part of mutton bone soup. Its processing method comprises the following steps:

[0026] Step 1. Wash the fresh potatoes, peel them with a peeling machine, cut them into pieces with a slitting machine, and cut them into 2cm×2cm×2cm cubes, then fry them at 160°C for 3 minutes, drain the oil and set aside.

[0027] Step 2. After washing the fresh mutton with bones, cut it into 3cm in length, 3cm in width and 2cm in thickness. If it is frozen mutton, it needs to be thawed at 0°C before using it. Fresh mutton is 100 parts by mass Add 1 part of table salt, 0.5 part of white sugar, 0.1 part of monosodium glutamate and 0.01 part of sodium erythorbate in parts by mass to carry out rolling and kneading for marinating. The pressure of the curing tank is -0.08Mpa. Repeat this, the marinating time is 5 hours, pre...

Embodiment 2

[0031] The invention provides a potato and mutton stew, which comprises the following components in parts by mass: 1 part of mutton meat base, 2 parts of fried potato pieces and 4 parts of mutton bone soup. Its processing method comprises the following steps:

[0032] Step 1. Wash the fresh potatoes, peel them with a peeling machine, cut them into pieces with a cutting machine, and cut them into 2cm×2cm×2cm cubes, then fry them at 190°C for 10 minutes, drain the oil and set aside.

[0033] Step 2. After washing the fresh cut mutton, cut it into 6cm in length, 4cm in width and 3cm in thickness. If it is frozen mutton, it needs to be thawed at 7°C before using it. It is calculated as 100 parts by mass of fresh mutton , add 2 parts of salt, 1 part of white sugar, 0.2 part of monosodium glutamate and 0.05 part of sodium erythorbate in parts by mass to carry out rolling and kneading for marinating. Repeatedly, the marinating time is 18h, precook the marinated meat base, the precoo...

Embodiment 3

[0037]The invention provides a potato and mutton stew, which comprises the following components in parts by mass: 1 part of mutton meat base, 1 part of fried potato pieces and 1 part of mutton bone soup. Its processing method comprises the following steps:

[0038] Step 1. Wash the fresh potatoes, peel them with a peeling machine, cut them into pieces with a slitting machine, and cut them into 2cm×2cm×2cm cubes, then fry them at 160°C for 3 minutes, drain the oil and set aside.

[0039] Step 2. After washing the fresh mutton with bones, cut it into 3cm in length, 3cm in width and 2cm in thickness. If it is frozen mutton, it needs to be thawed at 0°C before using it. Fresh mutton is 100 parts by mass Add 1 part of table salt, 0.5 part of white sugar, 0.1 part of monosodium glutamate and 0.01 part of sodium erythorbate in parts by mass for static pressure-swing pickling. The pickling temperature is 0°C and the vacuum degree is -70Kpa. , and then marinated at normal pressure for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com