Compound feed with improving meat quality of Wenchang chicken and preparation method thereof

A compound feed and functional technology is applied in the field of feed that can improve chicken quality, and achieves the effects of high conversion rate, reduction of breeding costs, and improvement of digestion and absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1

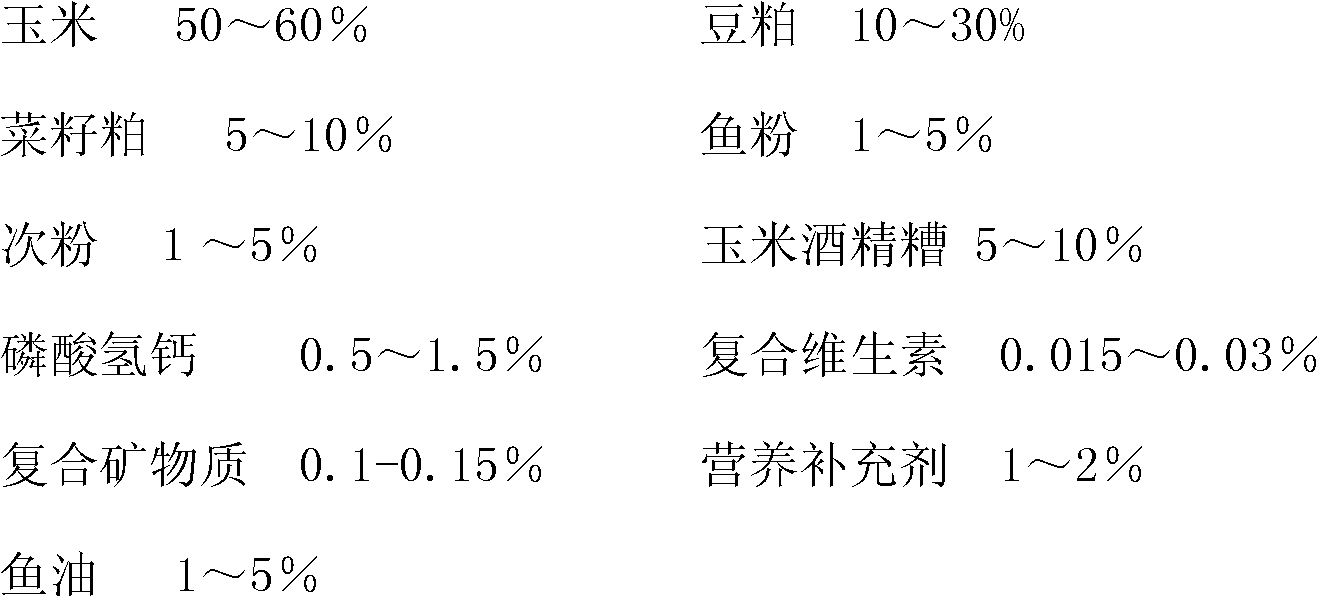

[0032] 1. Weigh the component raw materials in the following weight percentages:

[0033] Corn 50%, soybean meal 20%, rapeseed meal 5%, fish meal 2%, secondary meal 5%, corn distillers grains 5%, rice bran 5%, stone powder 1%, calcium hydrogen phosphate 1%, multivitamin 0.025%, compound mineral Substance 0.12%, nutritional supplement 2%, fish oil 3.855%. The nutritional supplement is composed of the following components in parts by weight: 30 lysine, 20 methionine, 10 threonine, 10 choline, 3.5 enzyme preparations and 20 baking soda.

[0034] The enzyme preparation is a mixture of xylanase, β-glucanase and β-mannanase.

[0035] 2. Mix the raw materials of the above components at room temperature and stir evenly.

[0036] 3. Grind the mixed raw materials through a pulverizer so that they can pass through a 150-micron screen.

[0037] 4. Move the pulverized material into the modulator, pass in 90°C steam for 5 minutes, and extrude and granulate at 95°C.

...

Example Embodiment

[0040] Example 2:

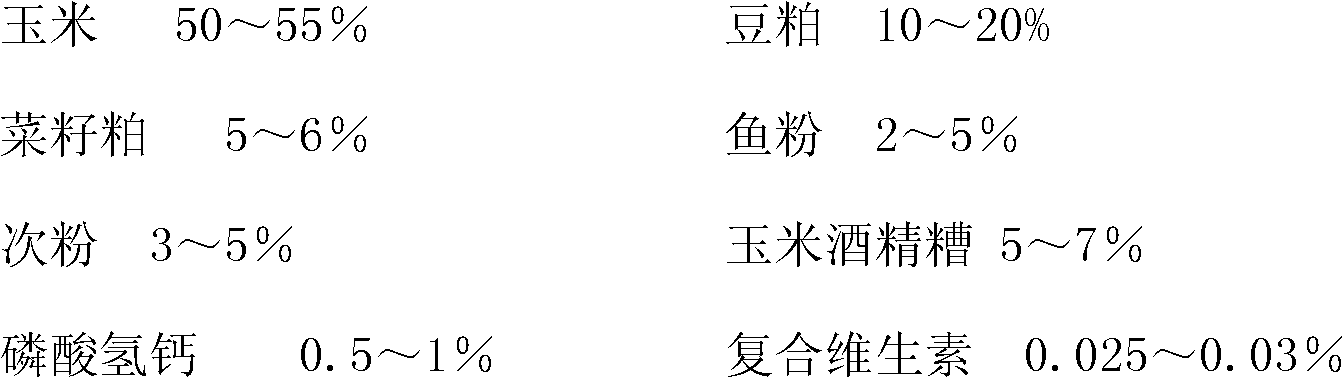

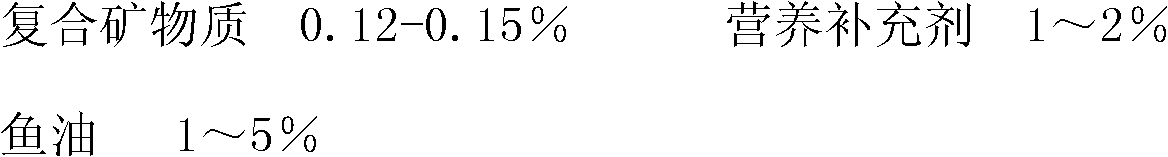

[0041] 1. Weigh the component raw materials in the following weight percentages:

[0042] Corn 60%, soybean meal 10%, rapeseed meal 10%, fish meal 1%, secondary meal 2%, corn distillers grains 7%, rice bran 1.885%, stone powder 0.5%, calcium hydrogen phosphate 1.5%, multivitamin 0.015%, compound mineral Substance 0.1%, Nutritional Supplement 1%, Fish Oil 5%. The nutritional supplement is composed of the following components in parts by weight: 10 lysine, 8 methionine, 2 threonine, 8 choline, 5 enzyme preparations, and 20 baking soda.

[0043] The enzyme preparation is a mixture of xylanase, β-glucanase and β-mannanase.

[0044] 2. Mix the raw materials of the above components at room temperature and stir evenly.

[0045] 3. Grind the mixed raw materials through a pulverizer so that they can pass through a 220-micron screen.

[0046] 4. Move the pulverized material into the modulator, pass in 85°C steam for 5 minutes, and extrude and granulate at 100°C. ...

Example Embodiment

[0049] Example 3:

[0050] 1. Weigh the component raw materials in the following weight percentages:

[0051] Corn 55%, soybean meal 15%, rapeseed meal 6%, fish meal 5%, secondary meal 3%, corn distillers grains 10%, rice bran 2%, stone powder 1%, calcium hydrogen phosphate 0.5%, multivitamin 0.03%, compound mineral Substance 0.15%, Nutritional Supplement 1.32%, Fish Oil 1%. The nutritional supplement is composed of the following components in parts by weight: 26 lysine, 12 methionine, 2 threonine, 5 choline, 3.5 enzyme preparations and 25 baking soda.

[0052] The enzyme preparation is a mixture of xylanase, β-glucanase and β-mannanase.

[0053] 2. Mix the raw materials of the above components at room temperature and stir evenly.

[0054] 3. Grind the mixed raw materials through a pulverizer so that they can pass through a 200-micron screen.

[0055] 4. Move the pulverized material into the modulator, pass in steam at 89°C for 4 minutes, and extrude and granulate at 92°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com