Production method of cube sugar

A production method and technology of sugar cubes, applied in the fields of application, food preparation, food science, etc., can solve the problem of no sugar cubes, etc., and achieve the effects of good masking of peculiar smell, pure and natural sweetness, and low GI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

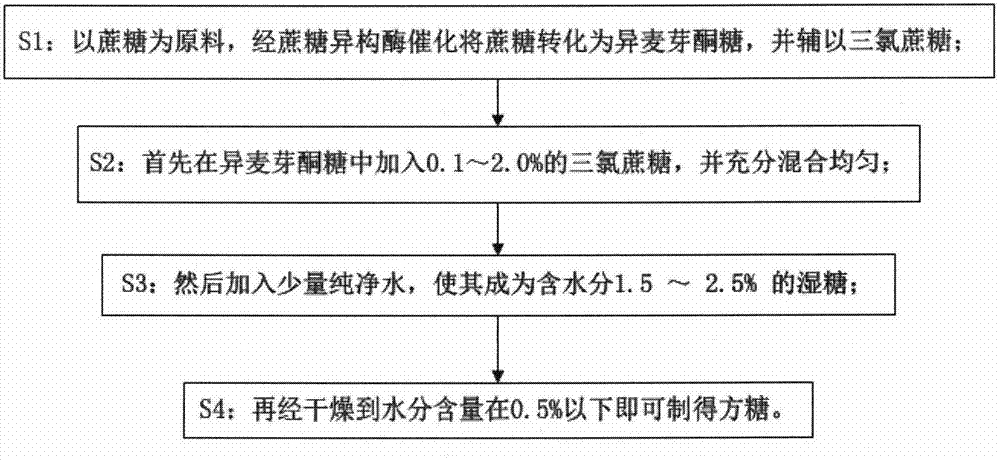

[0015] The method for producing sugar cubes provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0016] Such as figure 1 As shown, an embodiment of the present invention provides a method for producing sugar cubes, which is characterized by including the following steps:

[0017] S1: Using sucrose as a raw material, sucrose isomerase catalyzed the conversion of sucrose into isomaltulose, supplemented with sucralose;

[0018] S2: First, add 0.1-2.0% sucralose to isomaltulose, and mix well;

[0019] S3: Then add a small amount of purified water to make it into a wet sugar with a moisture content of 1.5 to 2.5%;

[0020] S4: After drying to the moisture content below 0.5%, sugar cubes can be obtained.

[0021] The GI value of the sugar cube is 44 and the II value is 0.22. Compared with the glucose, the GI value is 100 and the II value is 0.25, both of which are low. The isomaltulose in the raw materials not o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com