Method for preparing feed by transforming various cellulose-containing by-products by using Rhodospira rubrum rubrum

A technology of Rhodospirillum rubrum and cellulose, applied in animal feed, animal feed, applications, etc., can solve the problems of unseen feed production reports, long production cycle, etc., to shorten the production cycle, increase value, and expand raw materials category effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method of producing feed by acid hydrolysis with discarded grains, primary neutralization, ammoniation, secondary neutralization, and fermentation of Rhodospira rubrum comprises the following steps:

[0025] (1) Raw material handling. The dregs with a moisture content of 9.9% after drying are pulverized into 40 mesh uniform particles;

[0026] (2) Acid hydrolysis. Mix 100 parts of pulverized grains with 100 parts of 1% sulfuric acid solution, heat up to 90° C. for 1 h, and the process needs to replenish water to the original volume;

[0027] (3) One time neutralization. Add 1.6 parts of CaCO to the above acid hydrolyzate 3 Neutralize and stir evenly;

[0028] (4) Amination. Add 400 parts of 0.2% ammonia water to the above-mentioned neutralization product, and keep it airtight and insulated at 90° C. for 1.5 h;

[0029] (5) Secondary neutralization. The amide is cooled to 35 °C, and the pH is adjusted to 7.0 with a 1% concentration of phosphoric acid solution;...

Embodiment 2

[0034] The method for preparing feed by acidolysis of sauce residue, primary neutralization, ammoniation, secondary neutralization, and fermentation of Rhodospirillum rubrum comprises the following steps:

[0035] (1) Raw material handling. Grinding the dried sauce residue with a moisture content of 10.2% into 60-mesh uniform particles;

[0036] (2) Acid hydrolysis. Mix 100 parts of pulverized sauce residue with 150 parts of 1% phosphoric acid solution evenly, heat up to 100°C and keep it warm for 1.5 h. During the process, water needs to be replenished to the original volume;

[0037] (3) One time neutralization. Add 2 parts of CaCO to the above acid hydrolyzate 3 , and stir evenly;

[0038] (4) Amination. Add 250 parts of 0.3% ammonia water to the above-mentioned neutralization product, and keep it airtight and insulated at 95° C. for 2 h;

[0039] (5) Secondary neutralization. The amide is cooled to 36 ° C, and the pH is adjusted to 7.0 with 1% sulfuric acid solution...

Embodiment 3

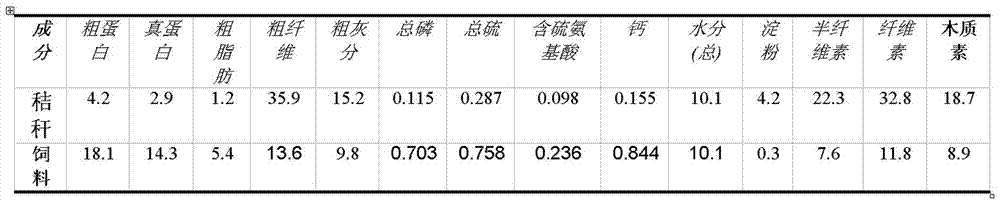

[0044] The method for preparing feed by acidolysis of rice straw, primary neutralization, ammoniation, secondary neutralization, and fermentation of Rhodospira rubrum includes the following steps:

[0045] (1) Raw material handling. Grinding the dry straw with a moisture content of 10.1% into 40 mesh uniform particles;

[0046] (2) Acid hydrolysis. Mix 100 parts of pulverized straw with 150 parts of 1% sulfuric acid solution evenly, heat up to 95°C for 1.5 h, and the process needs to replenish water to the original volume;

[0047] (3) One time neutralization. Add 1.8 parts of CaCO to the above acid hydrolyzate 3 , and stir evenly;

[0048] (4) Amination. Add 250 parts of ammoniacal liquor of 0.3% concentration to above-mentioned neutralization product, and keep airtight at 90 DEG C for 2.5 h;

[0049] (5) Secondary neutralization. The amide is cooled to 36°C, and the pH is adjusted to 7.0 with 1% phosphoric acid solution;

[0050] (6) Fermentation. Add 50 copies of R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com