Shallow-buried flexible pipeline construction method

A technology of flexible pipelines and construction methods, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of insufficient backfill compaction between pipeline layers and easy displacement of pipelines, etc., achieving significant social Economic benefit, high finish and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A construction method for a shallow buried flexible pipeline, the steps of which are:

[0082] 1) Measure and set out the line, excavate the trench, and the trench is trapezoidal.

[0083] 2) Backfill the pyrite cushion layer to the bottom of the trench, the thickness of the pyrex cushion layer is 5-7cm; tamp it with a flat vibrator; use a flat vibrator to tamp it more than four times, and the compaction degree is above 95%.

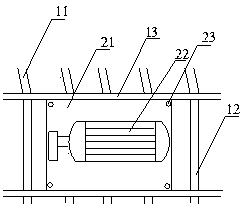

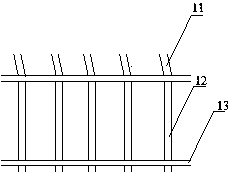

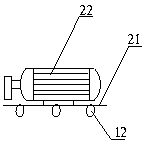

[0084] 3) Install and lay the first layer of pipes on the lime pad. When installing the first layer of pipes, set a pipe positioning frame every 5-10 meters to position the pipes to prevent the pipes from shifting and ensure that the distance between the pipes is consistent. Change; the first layer of pipes is laid according to the requirements of the drawing, adjust the straightness and pipe spacing, and then use the pipe positioning frame to position each pipe. The pipe positioning frame positions the pipes as follows Figure 5 shown.

[0085]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com