Transmission shifting mechanism assembly

A shifting mechanism and transmission technology, applied in the direction of instruments, controlled components, mechanical equipment, etc., can solve the problems of large installation space, unstable shifting performance, and a large number of parts, so as to achieve improved power, reliable quality, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] specific implementation plan

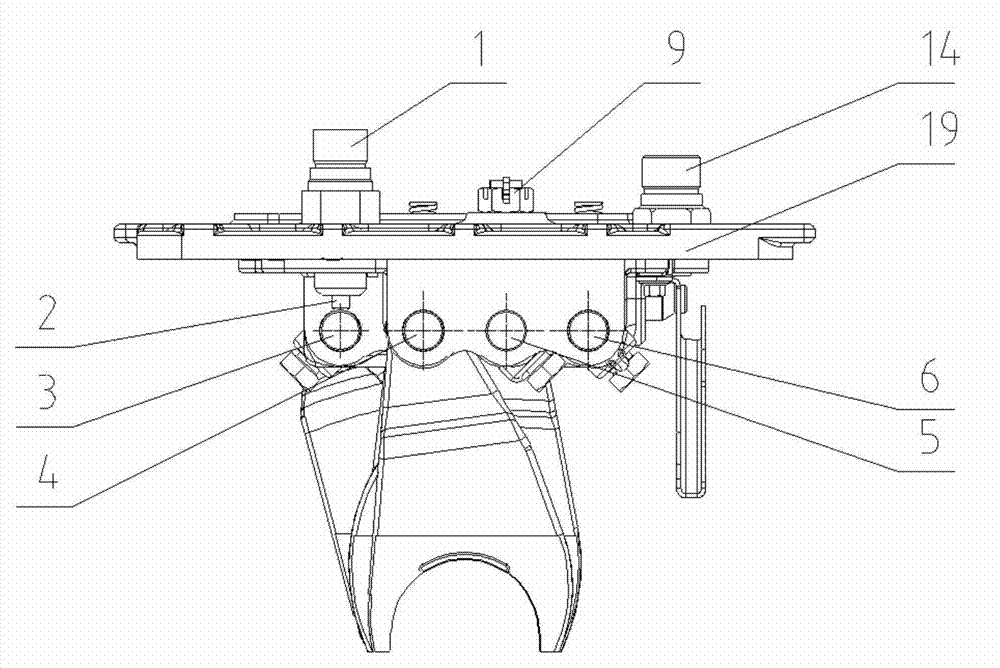

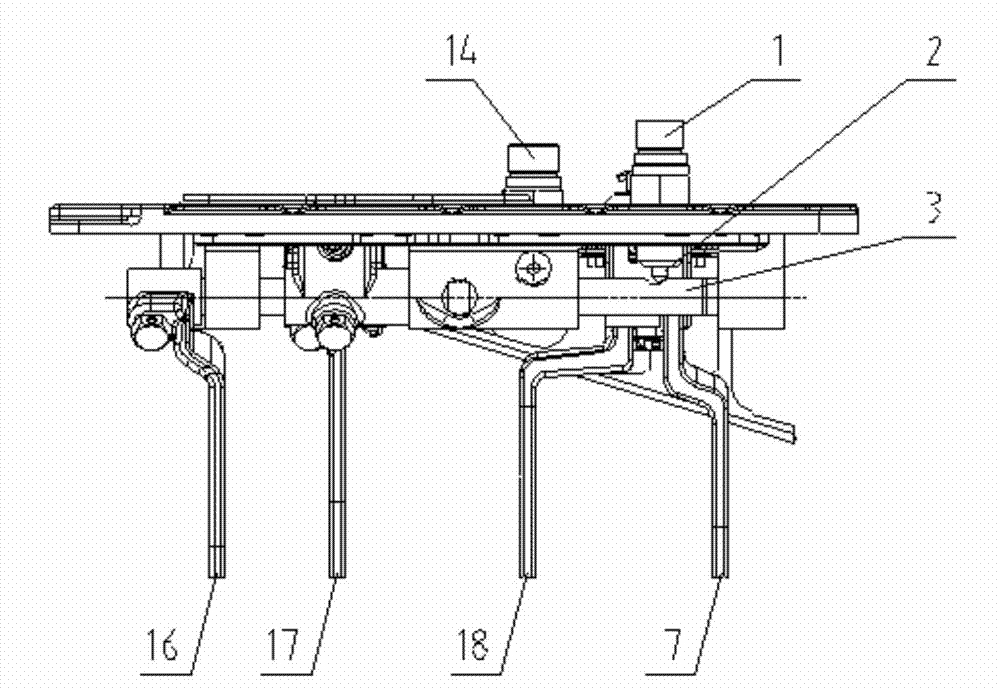

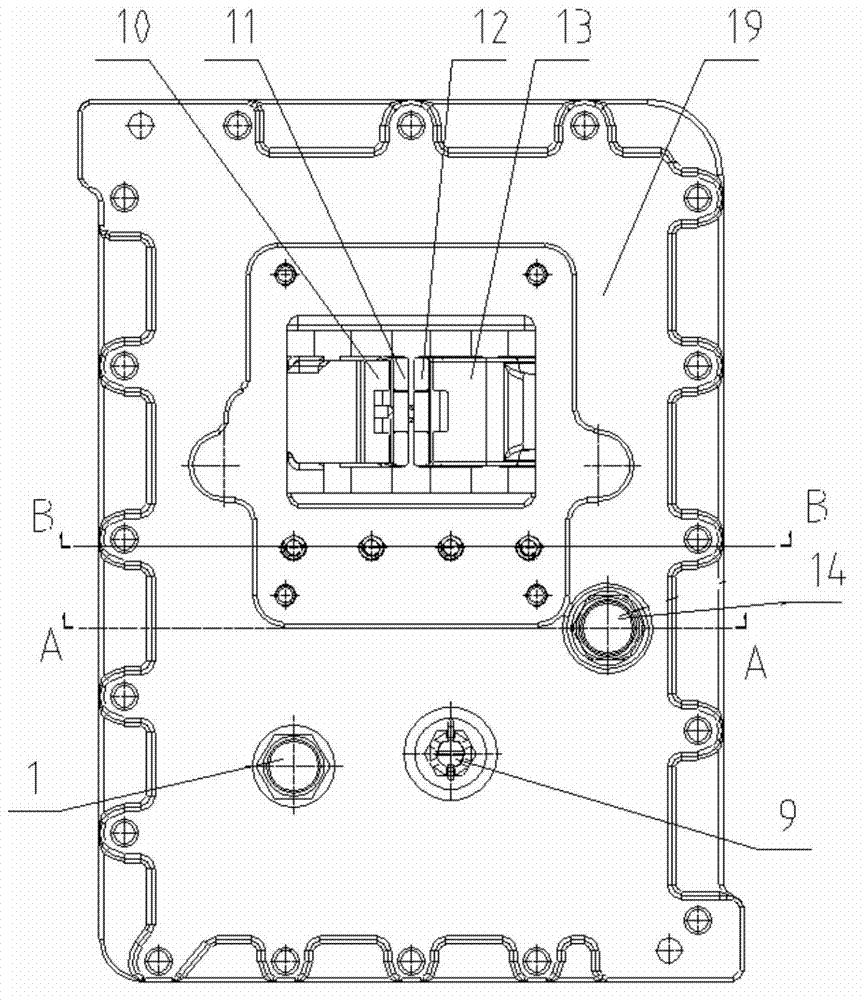

[0071] The present invention will be further described below in conjunction with the accompanying drawings: the heavy-duty transmission shift mechanism assembly is composed of a transmission upper cover assembly and four fork shaft assemblies, and a shift guide block and a shift dial are fixed on each shift fork shaft The fork and the shift guide block form four gear selection positions. The fork legs of the shift fork are respectively inserted into the grooves of the gear sleeve. The neutral and reverse switches are installed on the upper cover of the transmission.

[0072] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0073] refer to figure 1 , Figure 4 , the gearshift mechanism assembly of the present invention comprises transmission loam cake 19 and first and second gear shift fork shaft 4, third and fourth gear shift fork shaft 5, fifth and sixth gear shift fork shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com