Integrated multifunctional hydraulic component

A hydraulic component and multi-functional technology, which is applied in the direction of engine components, servo motor components, fluid pressure actuators, etc., can solve the problems of large volume, complex system and high cost of the hydraulic control system, so as to reduce the number of parts and improve the process performance , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

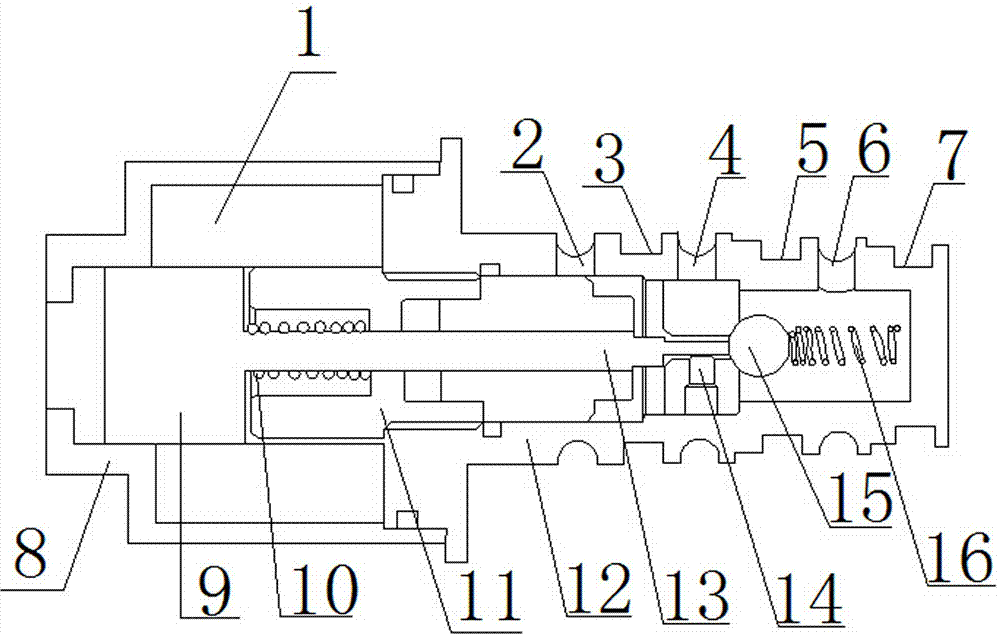

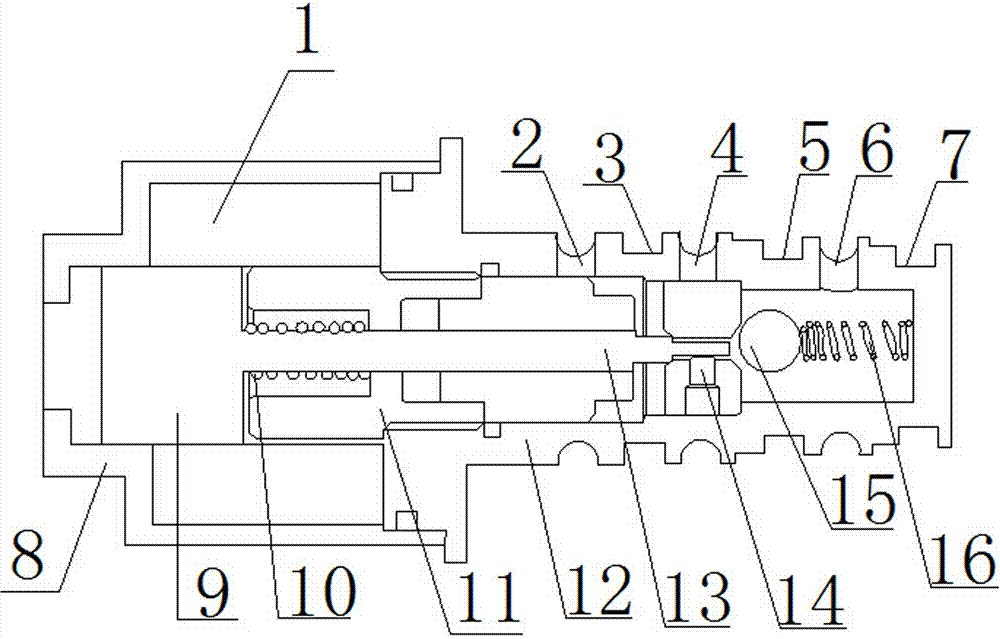

[0011] Such as figure 1 , 2 As shown, an integrated multifunctional hydraulic component includes a magnetic yoke 8, a valve body 12, a valve core 13, and a double-sided sealing seat 14. The magnetic yoke is provided with an electromagnetic coil 1 inside the electromagnetic coil A movable iron 9 is provided, and the movable iron is connected with a fixed iron core 11, a return spring 10 is arranged between the fixed iron core and the valve core, and a liquid inlet 2 is sequentially arranged on the valve body from the end close to the solenoid coil. , Sealing ring Ⅰ3, hydraulic regulating port 4, sealing ring Ⅱ5, pressure relief port 6, sealing ring Ⅲ 7, the central hole of the double-sided sealing seat is connected with the hydraulic regulating port, one side is connected with the valve core, and the other side is provided There is a steel ball 15, the small end face of the valve core is connected with the steel ball, the large end face is connected with one side of the double-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com