Hydrogen peroxide orientation catalytic composite additive and application of additive to pretreatment of cotton

A technology of hydrogen peroxide and composite additives, applied in the field of textile dyeing and finishing, to achieve the effects of reducing the dichromate index, reducing energy consumption costs, and simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

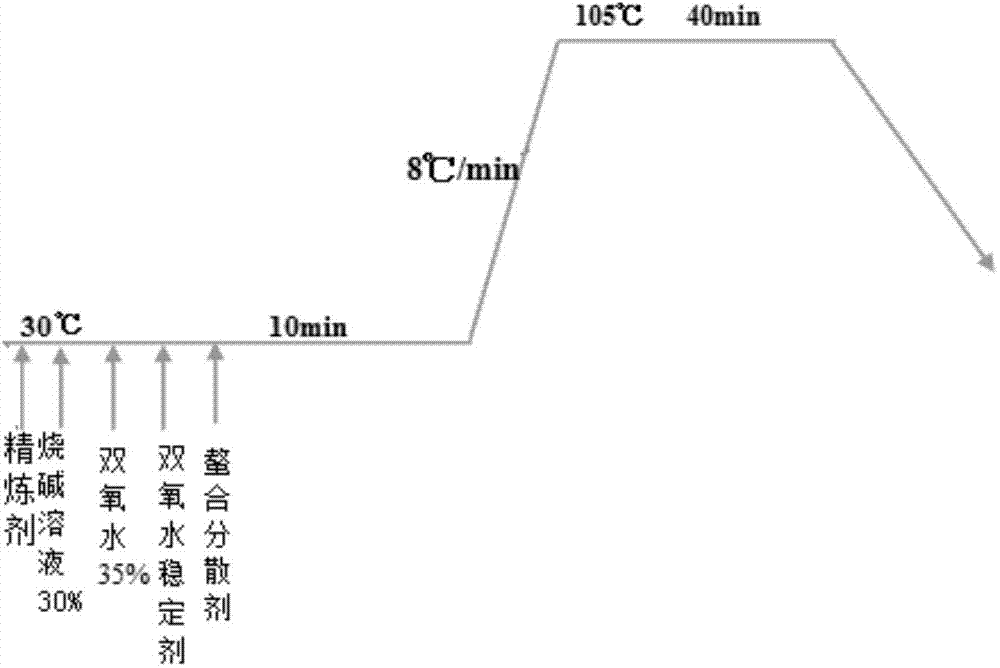

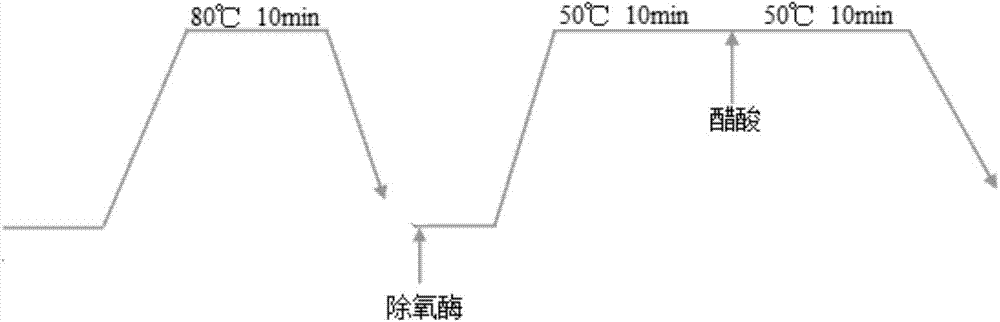

Method used

Image

Examples

Embodiment 1

[0097] Hydrogen peroxide positioning catalysis composite promoter XAT is composed of the following raw materials according to mass percentage:

[0098] Copper sulfate 3%, iron sulfate 0.002%, ammonia 3%, lactic acid 3%, dodecyl dimethyl benzyl ammonium chloride 3%, flat addition O3%, sodium dodecyl sulfonate 3%, twelve Sodium alkyl sulfate 3%, 78.998% of purified water, the total content of the above components is 100%;

[0099] The preparation method of hydrogen peroxide positioning catalysis composite auxiliary agent XAT, weigh the following raw materials according to mass percentage: copper sulfate 3%, iron sulfate 0.002%, ammonia 3%, lactic acid 3%, dodecyl dimethyl benzyl chloride Ammonium sulfide 3%, flat addition of O3%, sodium dodecyl sulfonate 3%, sodium lauryl sulfate 3%, 78.998% of purified water, the total content of the above components is 100%; will be weighed Heat purified water to 40°C; add the weighed copper sulfate, iron sulfate, ammonia, lactic acid, dodecyl dim...

Embodiment 2

[0103] Hydrogen peroxide positioning catalysis composite promoter XAT is composed of the following raw materials according to mass percentage:

[0104] Copper sulfate 2.5%, iron sulfate 0.001%, ammonia 2.5%, citric acid 2.5%, dodecyl dimethyl benzyl ammonium chloride 2.5%, flat plus 0.25%, sodium dodecyl sulfonate 2.5% , Sodium lauryl sulfate 2.5%, 82.499% of purified water, the total content of the above components is 100%;

[0105] The preparation method of hydrogen peroxide positioning catalysis composite promoter XAT, weigh the following raw materials according to mass percentage:

[0106] Copper sulfate 2.5%, iron sulfate 0.001%, ammonia 2.5%, citric acid 2.5%, dodecyl dimethyl benzyl ammonium chloride 2.5%, flat plus 0.25%, sodium dodecyl sulfonate 2.5% , Sodium lauryl sulfate 2.5%, 82.499% of purified water, the total content of the above components is 100%; the weighed copper sulfate, iron sulfate, ammonia, citric acid, dodecyl dimethyl benzyl Ammonium chloride, flat additi...

Embodiment 3

[0110] Hydrogen peroxide positioning catalysis composite promoter XAT is composed of the following raw materials according to mass percentage:

[0111] Copper chloride 5%, iron chloride 0.003%, ammonia 3.5%, sulfosalicylic acid 3.5%, dodecyl dimethyl benzyl ammonium chloride 3.5%, flat plus O3.5%, dodecyl Sodium sulfonate 3.5%, sodium lauryl sulfate 3.5%, 73.997% of purified water, the total content of the above components is 100%;

[0112] The preparation method of hydrogen peroxide positioning catalysis composite promoter XAT, weigh the following raw materials according to mass percentage:

[0113] Copper chloride 5%, iron chloride 0.003%, ammonia 3.5%, sulfosalicylic acid 3.5%, dodecyl dimethyl benzyl ammonium chloride 3.5%, flat plus O3.5%, dodecyl Sodium sulfonate 3.5%, sodium lauryl sulfate 3.5%, 73.997% of purified water, the total content of the above components is 100%; the weighed copper chloride, ferric chloride, ammonia, and sulfosalicin Acid, dodecyl dimethyl benzyl am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com