Preparation method for Cu3BiS3 micro/nanosheet

A technology of precursor and copper precursor, which is applied in the field of preparation of Cu3BiS3 micro/nanosheets, can solve the problems of high requirements for reagents and equipment, complicated process, difficult to popularize, etc., and achieves the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

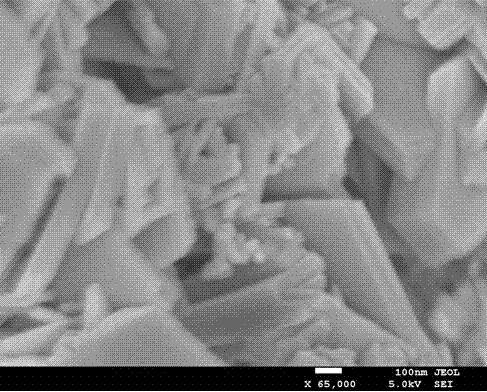

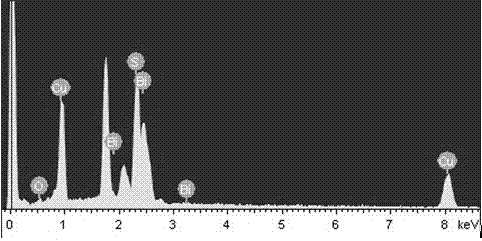

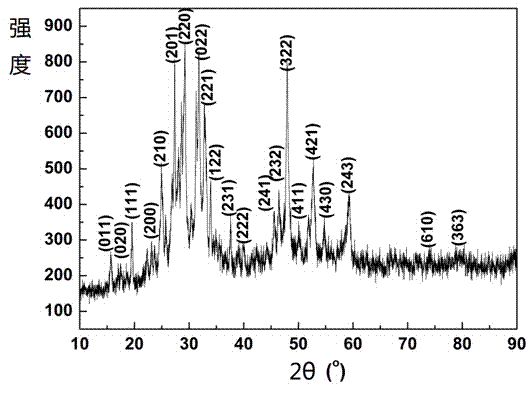

Image

Examples

Embodiment 1

[0026] Step 1. Dissolve 3 mmol of copper nitrate, 1 mmol of bismuth nitrate, 3 mmol of thiourea, and 2 mmol of reduced glutathione in 80 mL of water to prepare a solution, and adjust the pH of the solution to 10;

[0027] Step 2. Transfer the above solution to a hydrothermal reaction kettle for heating, control the temperature at 90°C, and react for 10 minutes, then naturally cool to room temperature and centrifuge at a speed of 10,000 r / min, and use deionized water and After washing with ethanol 10 times and drying, Cu 3 BY 3 micro / nanochips.

Embodiment 2

[0029] Step 1. Dissolve 3 mmol of copper sulfate, 1 mmol of bismuth nitrate, 3 mmol of thiourea, and 2 mmol of reduced glutathione in 80 mL of water to prepare a solution, and adjust the pH of the solution to 5;

[0030] Step 2. Transfer the above solution to a hydrothermal reactor for heating. Control the temperature at 180°C. After reacting for 6 hours, cool down to room temperature naturally and centrifuge at a speed of 12000 r / min. Use deionized water and ethanol to dissolve the precipitate obtained by centrifugation. After washing 10 times and drying, Cu 3 BY 3 micro / nanochips.

Embodiment 3

[0032] Step 1. Dissolve 3 mmol of copper acetate, 1 mmol of bismuth acetate, 3 mmol of thioacetamide, and 4 mmol of reduced glutathione in 80 mL of deionized water to prepare a solution, and adjust the pH of the solution to 6;

[0033] Step 2. Transfer the above solution to a hydrothermal reactor for heating. Control the temperature at 120°C. After reacting for 6 hours, cool down to room temperature naturally and centrifuge at a speed of 10,000 r / min. Use deionized water and ethanol to dissolve the precipitate obtained by centrifugation. After washing 10 times and drying, Cu 3 BY 3 micro / nanochips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com