Automatic following control system for machine tool

A machine tool, automatic technology, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of inconvenient adjustment of the air outlet position, the inability to guarantee the cooling effect, and the inability to realize the synchronous movement of the nozzle and the machining tool of the machine tool, etc. To achieve the effect of ensuring the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

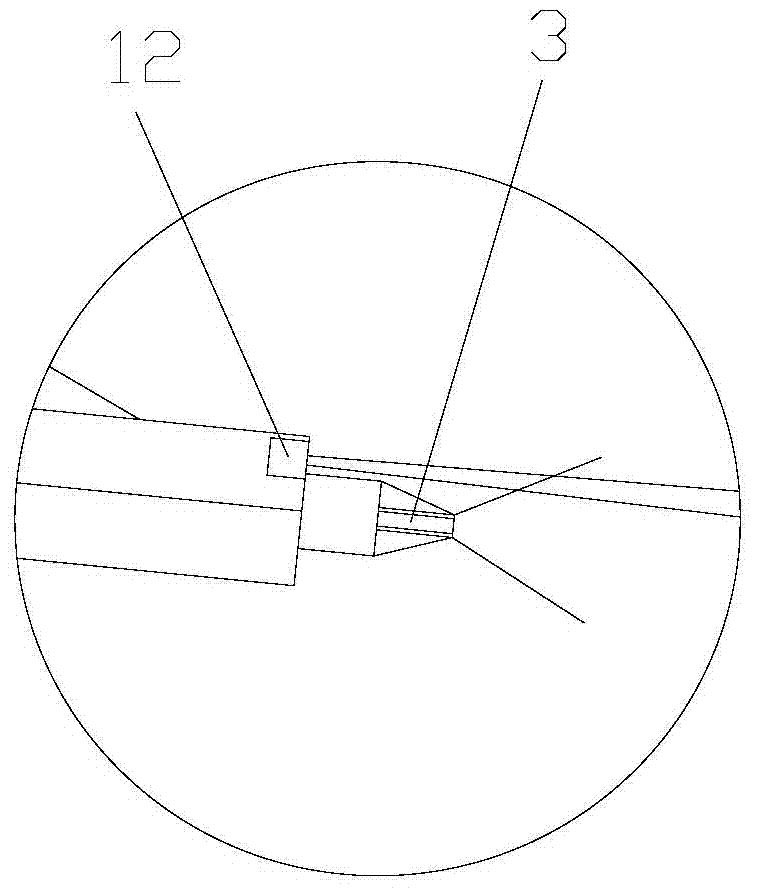

[0014] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 The enlarged view at A in the middle is as shown in the figure: the machine tool automatic follow-up control system of this embodiment includes a cooling device 1, a mechanical arm 2, a controller (not shown in the figure) and a tool for detecting the position of the machine tool 4 Detection device, the cold air nozzle 3 of described cooling device 1 is fixed on mechanical arm 2, and described detection device comprises camera, and the signal output end of camera is connected to controller (not shown in the figure); Described controller (not shown in the figure) shown) is connected to the mechanical arm 2 for image recognition and controls the mechanical arm 2 to keep the relative position between the cold air nozzle 3 and the machine tool 4 unchanged, and the controller (not shown) integrates image recognition software , can identify the position of the tool 4 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com