Chromic oxide-doped carbon nitride composite visible photocatalyst, and preparation method and application thereof

A technology of chromium trioxide and nitrogen carbide, which is applied in the field of visible light catalysis, can solve the problems of low activity, achieve the effects of simple preparation process, solve environmental problems, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

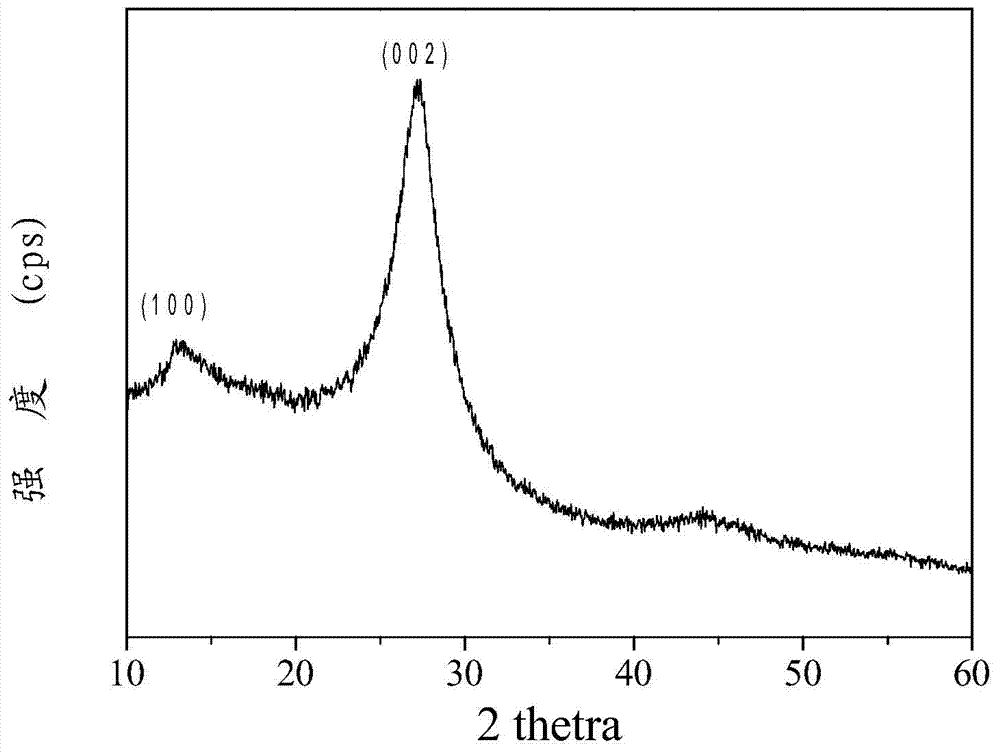

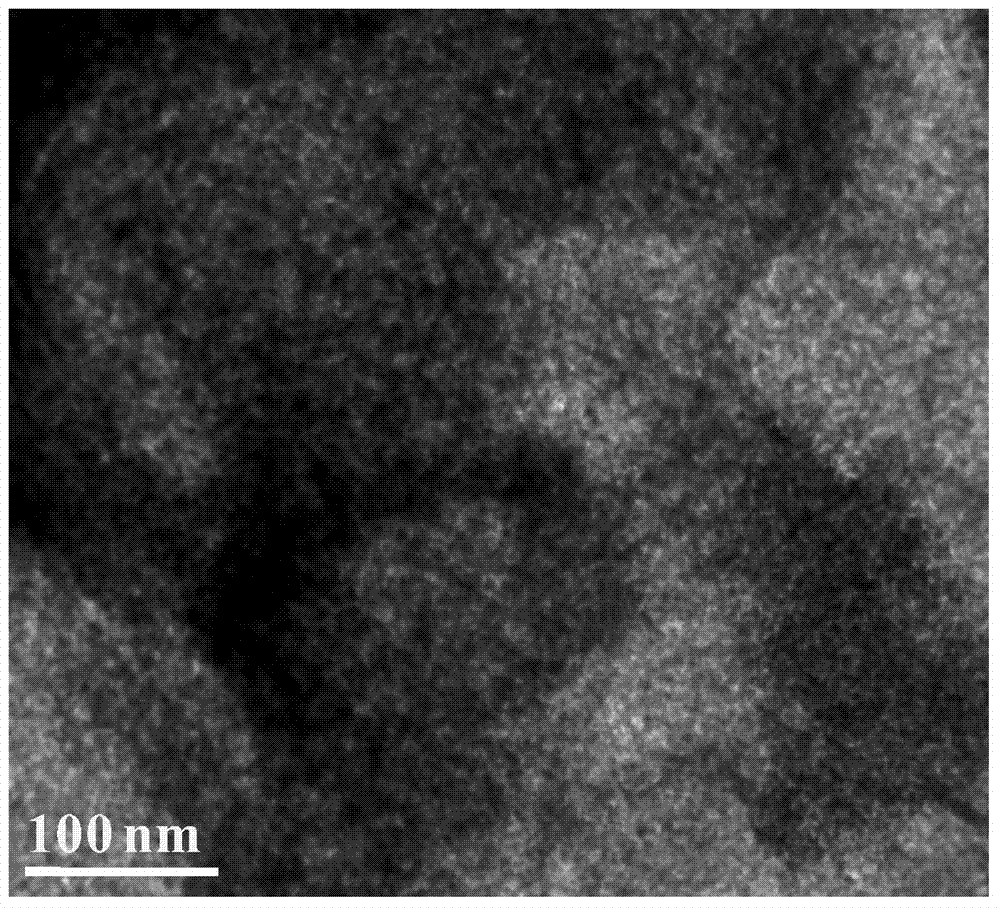

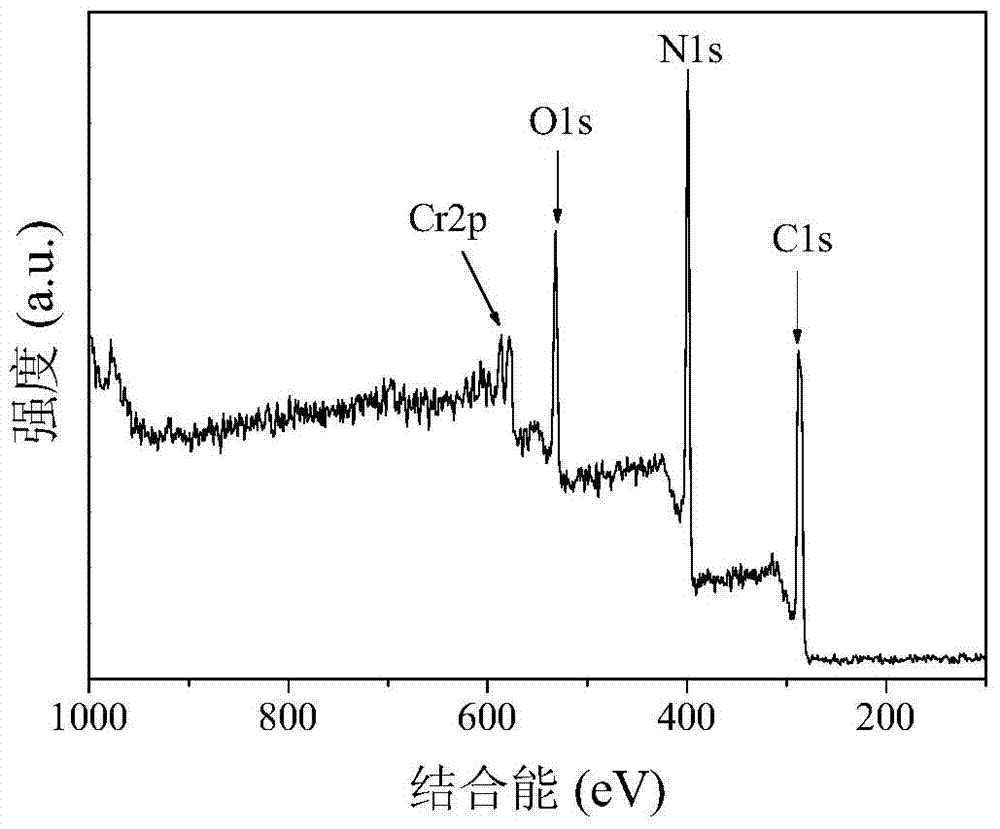

[0032] Weigh 4.0g of dicyandiamide and dissolve it in water. Then weigh 0.4g Cr(NO 3 ) 3 9H 2 Dissolve O in the above solution, keep stirring, and dry the water. Then put it into a tube furnace, under nitrogen protection, and calcined at 600°C for 4h to obtain the corresponding Cr 2 o 3 g-C 3 N 4 Composite photocatalytic materials. Test the photocatalytic degradation performance of the material for rhodamine B, such as Figure 4 shown.

Embodiment 2

[0034] Weigh 4.0g of dicyandiamide and dissolve it in water. Then weigh 0.8g Cr(NO 3 ) 3 9H 2 Dissolve O in the above solution, keep stirring, and dry the water. Then put it into a tube furnace, under nitrogen protection, and calcined at 600°C for 4h to obtain the corresponding Cr 2 o 3 g-C 3 N 4 Composite photocatalytic materials. The photocatalytic degradation performance of the material for Rhodamine B was tested. After 9 hours of visible light irradiation, the removal rate of Rhodamine B could reach 70.1%.

Embodiment 3

[0036] Weigh 4.0g of dicyandiamide and dissolve it in water. Then weigh 0.04g Cr(NO 3 ) 3 9H 2 Dissolve O in the above solution, keep stirring, and dry the water. Then put it into a tube furnace, under nitrogen protection, and calcined at 600°C for 4h to obtain the corresponding Cr 2 o 3 g-C 3 N 4 Composite photocatalytic materials. The photocatalytic degradation performance of the material for rhodamine B was tested. After 9 hours of visible light irradiation, the removal rate of rhodamine B could reach 51.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com